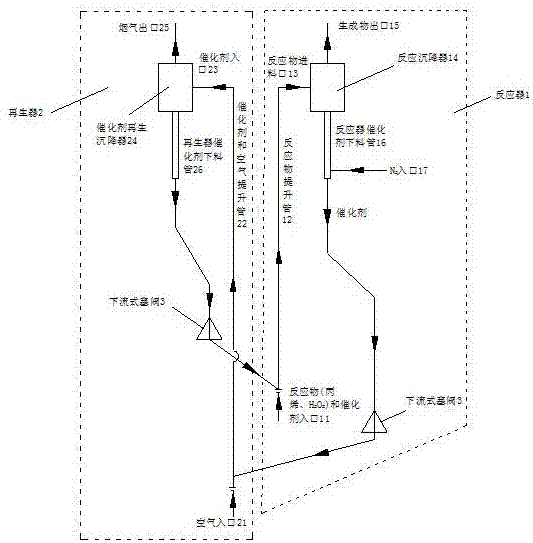

Down-flow plug valve for fluidization up-flow multi-reactor serial-connection and regeneration technique

A reactor and downstream technology, applied in the chemical and petroleum fields, can solve the problems of high parking costs, short service life, frequent driving, etc., and achieve the effects of improving safety, reducing costs, and easy feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

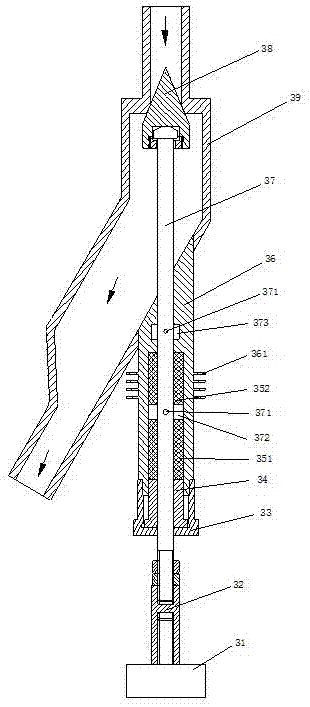

[0029] Example 1 Downflow plug valve

[0030] See figure 1 , Downflow plug valve, which includes: electric mechanism 31, transmission mechanism 32, valve seat 33, adjustment sleeve 34, sealing ring, valve stem sleeve 36, valve stem 37, valve head 38, valve body 39;

[0031] Described valve body 39, its upper part is parallel with valve rod 37, is vertically arranged, and lower part is inclined; Described valve rod 37 is a rotary body, and its lower end is connected with transmission mechanism 32, and upper end is connected with valve head 38; Valve head 38 is a cone, its lower end links to each other with valve stem 37, and its outer surface matches with valve body 39 upper end entrance; Described valve stem cover 36 is a rotary body, is fixed as one with valve body 39, The upper part of the valve body 39 is on the same axis;

[0032] The valve seat 33 is located at the bottom of the stem sleeve 36, and its upper end is connected with the valve stem sleeve 36; the sealing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com