Waste heat recycling device of transformer substation and transformer substation equipped with waste heat recycling device

A waste heat recovery device and substation technology, applied in lighting and heating equipment, fluid heaters, etc., can solve problems such as waste of heat, air heat pollution, etc., and achieve the effects of improving operating efficiency, increasing service life, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

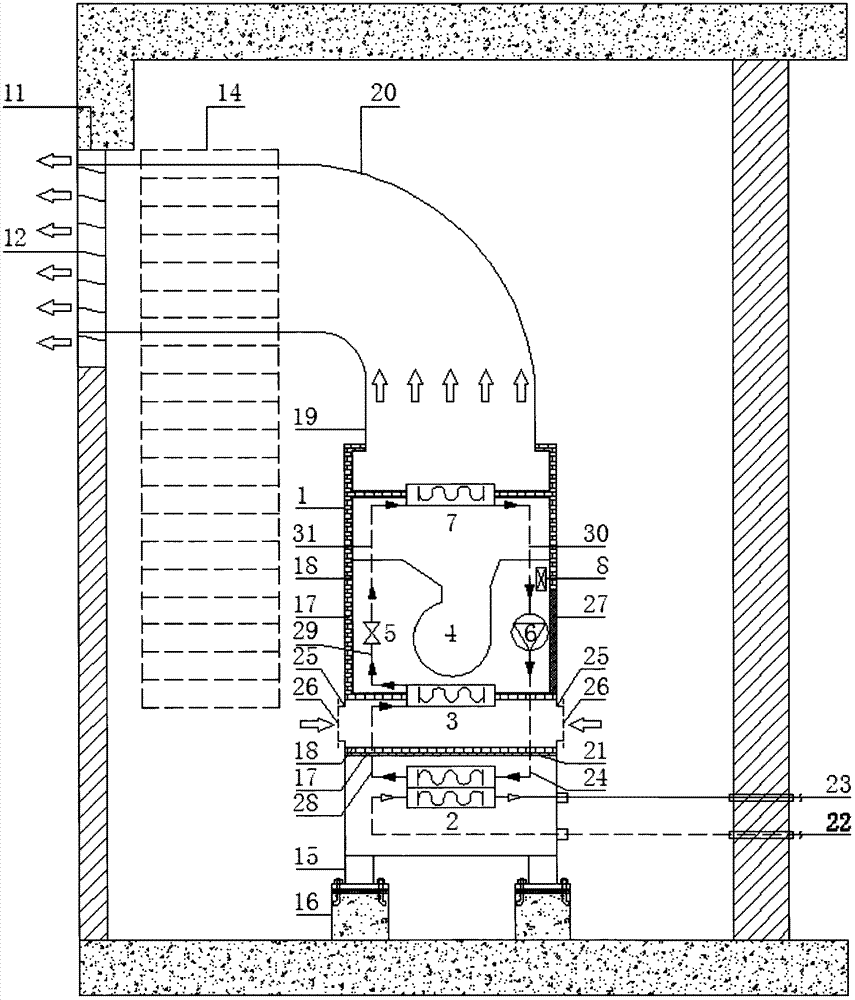

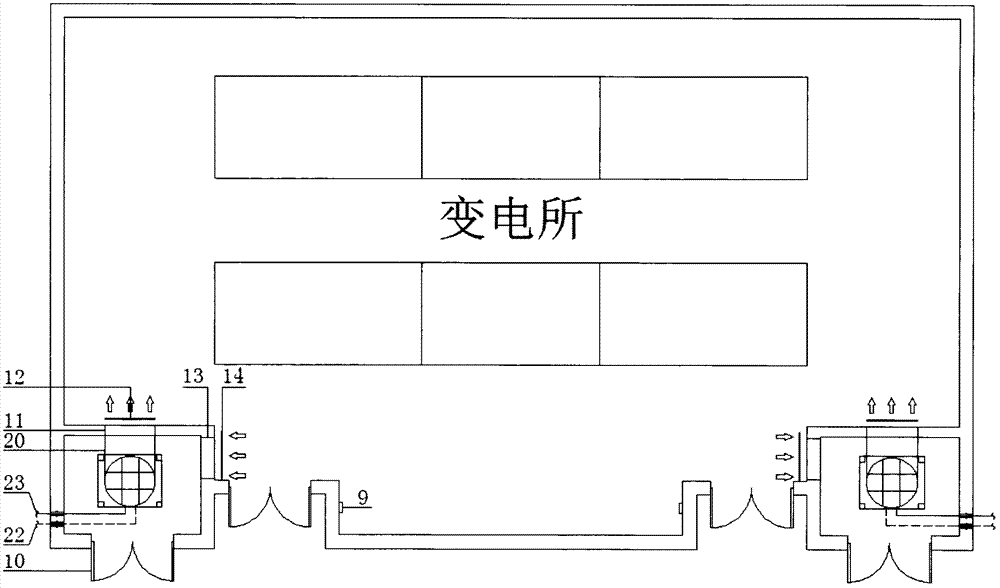

[0015] Such as figure 1 , figure 2 As shown, according to the layout of the internal equipment of the substation, the waste heat recovery device of the substation is installed in the waste heat recovery machine room at both ends of the substation; the inspection door 10 is opened on the outer wall of the waste heat recovery machine room, and the waste heat recovery machine room Air supply port 11 is set on the wall, and air supply louvers 12 are arranged inside the air supply port 11. In order to ensure the air supply effect, the air supply port 11 is set close to the ceiling of the substation; Return air louvers 14 are arranged close to the ceiling of the substation for ensuring the return air effect.

[0016] Such as figure 1 As shown, the substation waste heat recovery device includes: shell 1, water heater 2, recooler 3, air blower 4, expansion valve 5, compressor 6, and evaporator 7; where:

[0017] The shell 1 is a closed frame structure. Four bases 15 are set at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com