Method for testing biaxial yield and hardening behaviors of sheet metal

A metal plate and behavioral technology, applied in the preparation of test samples, using stable tension/pressure to test the strength of materials, measuring devices, etc., can solve problems such as large measurement errors, difficult positioning, and a large number of numerical simulations. Achieve the effect of easy positioning and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

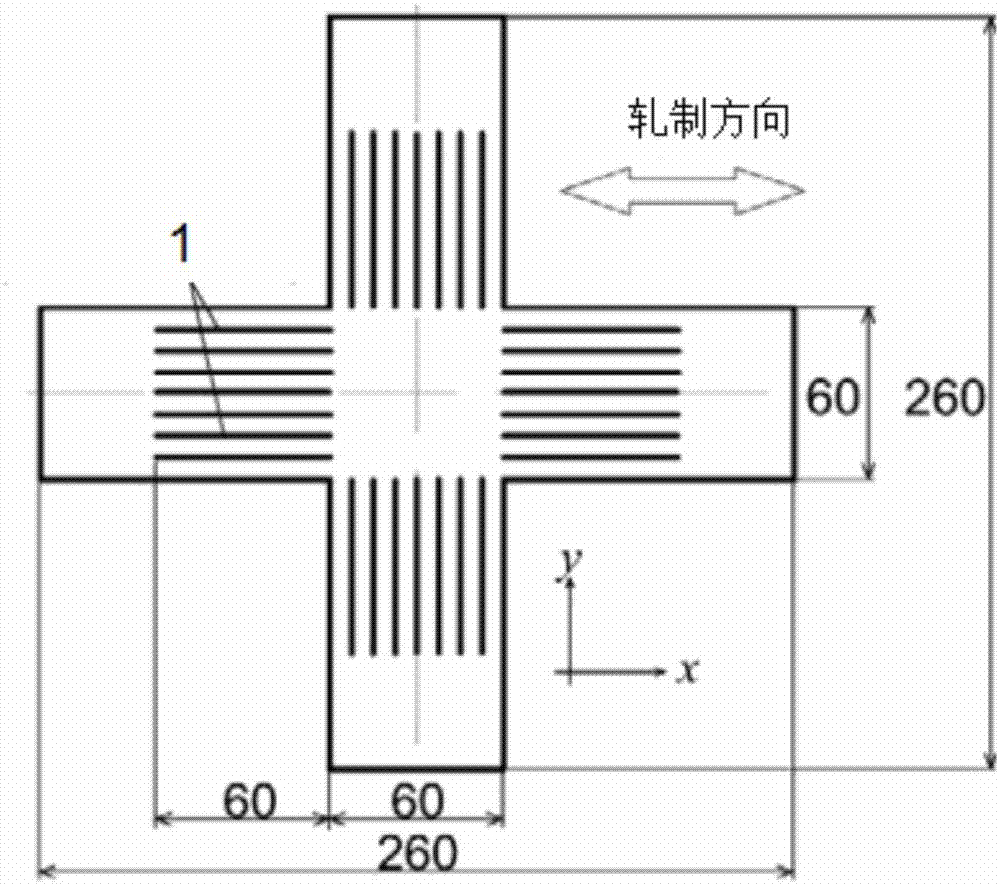

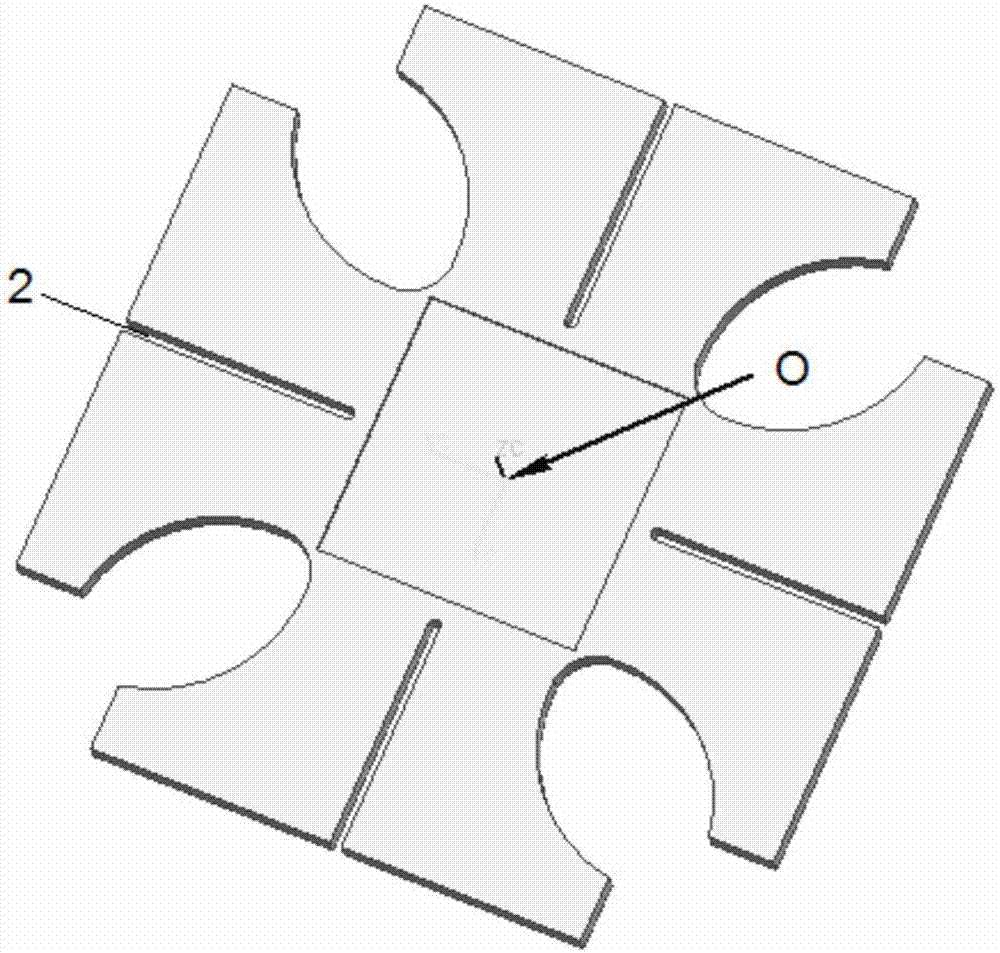

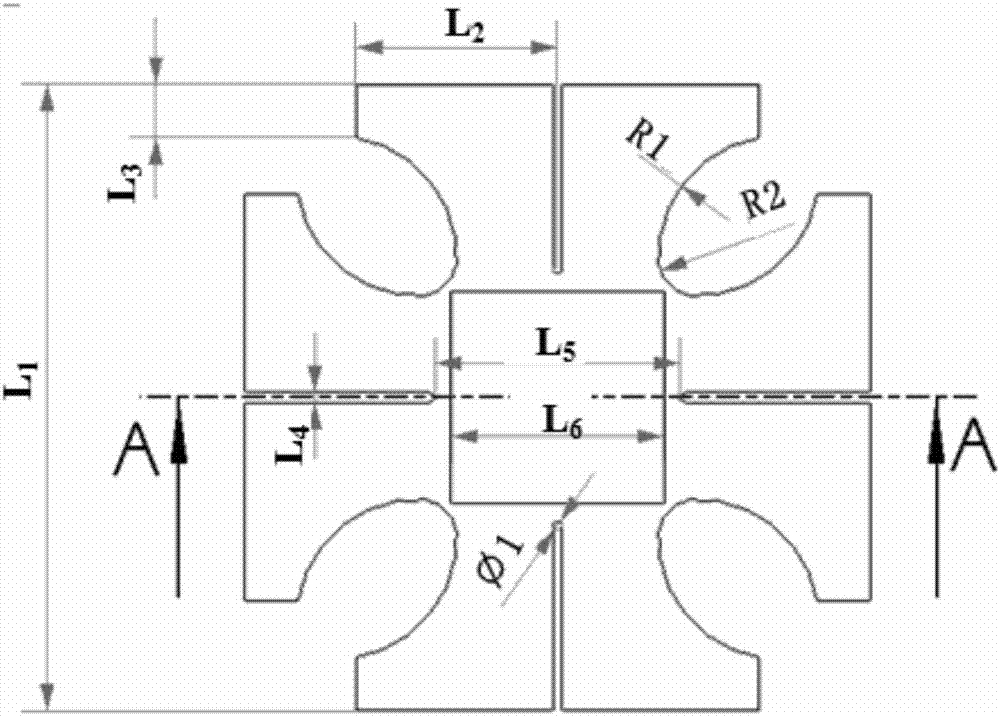

[0042] Such as Figure 3(a)-Figure 3(b) As shown, the size of the sample in this embodiment: the used notch fillet radius R1 = 9.08mm, R2 = 2.77mm, the size of the central deformation zone L 5 =16mm,L 6 =18.5mm, T 1 = 0.9mm and T 2 = 1.5 mm.

[0043] The present embodiment adopts numerical method to illustrate feasibility and accuracy of the present invention, and its basic process is as follows:

[0044] (1) Cruciferous sample model. The model is modeled with 3D modeling software and meshed. The parameters in the model are fitted by uniaxial experimental yield stress and anisotropy parameters, and Mises, Hill 48, Balart_Lian 89, and YLD 2000 are used to verify the feasibility and accuracy of the samples.

[0045] (2) Loading of cross-shaped sample model. Apply stress σ on the x-axis and y-axis respectively x :σ y 1:1, 1:0.4, 1:0.2, 1:0.01 load conditions.

[0046] (3) Comparison of model validation. Take the central strain measurement point O as the deformation ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com