Split type ultrasonic precise distance measuring device

A distance measuring device and ultrasonic technology, applied in the field of ultrasonic waves, can solve the problems of high requirements for the emission echo surface, the reflection angle cannot be too large, and the echo interference cannot be formed, so as to achieve the advantages of simple operation, reduced use conditions, and expanded use occasions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

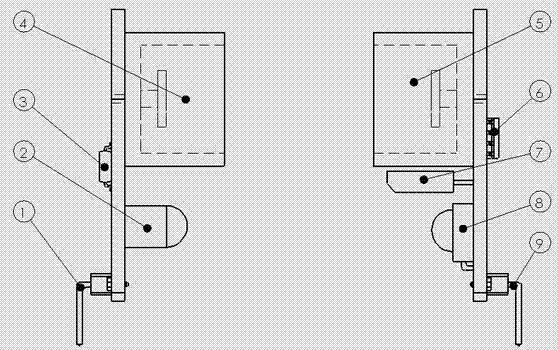

[0019] Such as figure 1 As shown, a split-type ultrasonic precision distance measuring device, the distance measuring device includes:

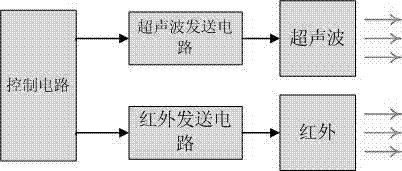

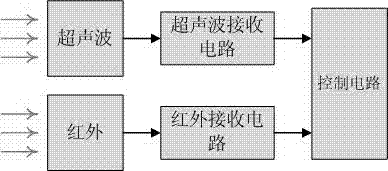

[0020] A central processing chip at the transmitting end is connected with the infrared transmitting tube and the ultrasonic transmitting probe to control the signal emission of the infrared transmitting tube and the ultrasonic transmitting probe;

[0021] An infrared emitting tube, connected to the central processing chip at the transmitting end, and sending an infrared signal according to the control signal of the central processing chip at the transmitting end;

[0022] An ultrasonic transmitting probe, which is connected to the central processing chip at the transmitting end, and sends ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com