Cable pulling and cutting device

A cutting device and cable pulling technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low precision, difficult cutting accuracy, production efficiency and enterprise production benefit reduction, etc., to achieve cable The traction process is fast and safe, the device layout is simple and efficient, and the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

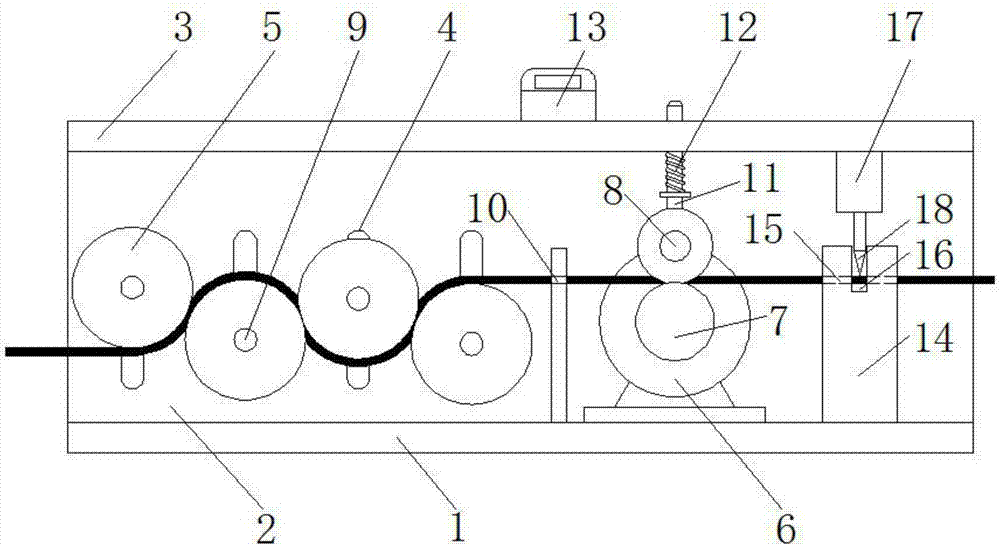

[0017] Such as figure 1 As shown, a cable pulling and cutting device includes a fixed bracket, a pulling assembly and a cutting assembly, the pulling assembly and the cutting assembly are installed on the fixing bracket, the fixing bracket includes a horizontally arranged bottom plate 1, a vertically arranged side plate 2 and The bottom plate 1 is parallel to the top plate 3, and the side plate 2 is longitudinally provided with an adjustment hole array composed of oblong adjustment holes 4. There are at least three adjustment holes 4, preferably four adjustment holes 4 in this embodiment.

[0018] The traction assembly includes a tension adjustment wheel 5, a speed regulating moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com