Automatic cable shearing and bundling device

A strapping device and automatic technology, applied in the parts, packaging, transportation and packaging of strapping machinery, can solve the problems of low cable cutting and bundling efficiency, low degree of automation, and easy cable damage, and achieve high cutting and bundling efficiency. , high degree of automation, fast and safe effect of cable pulling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

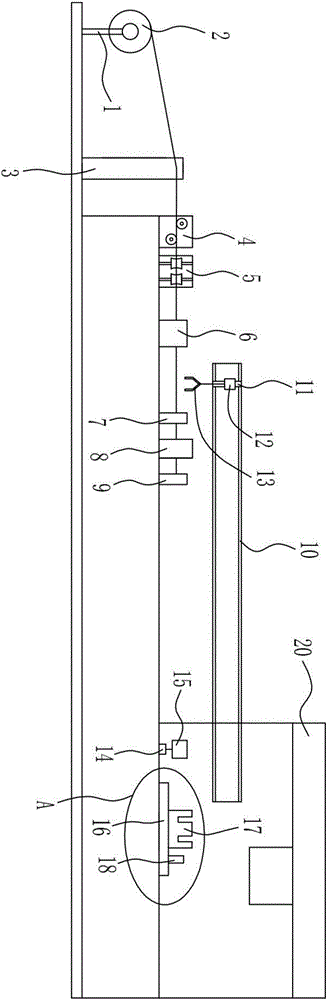

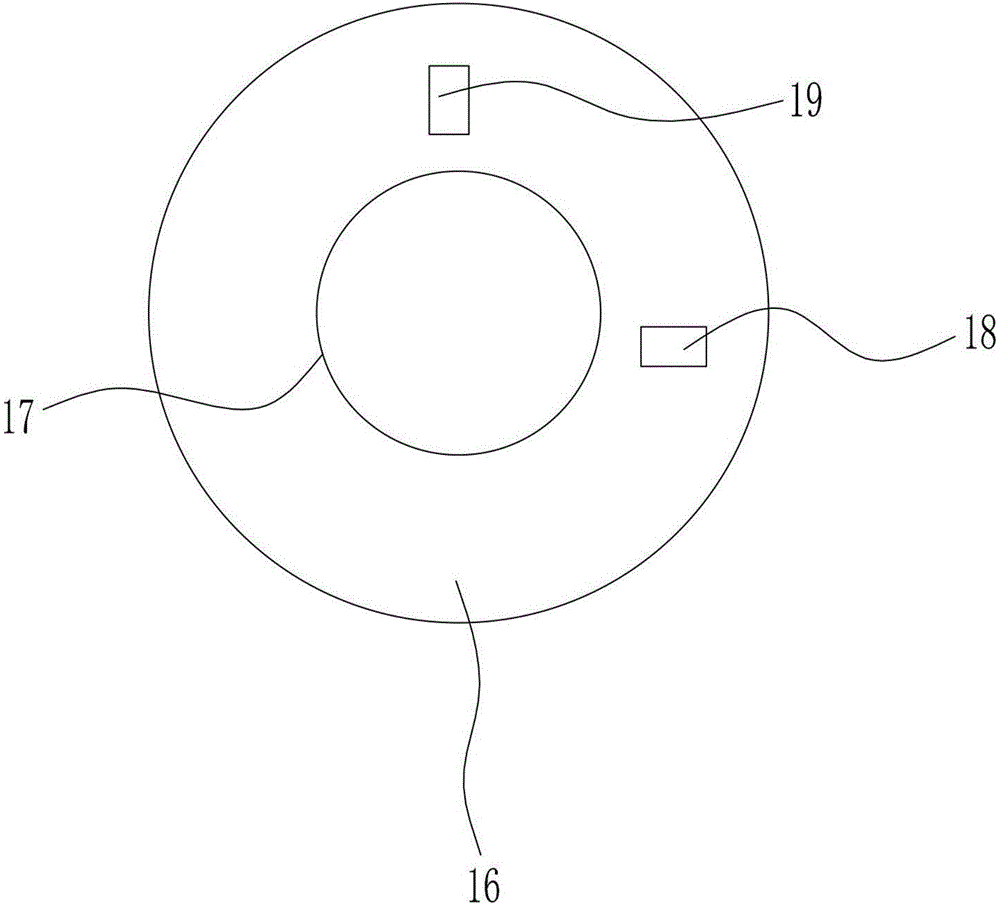

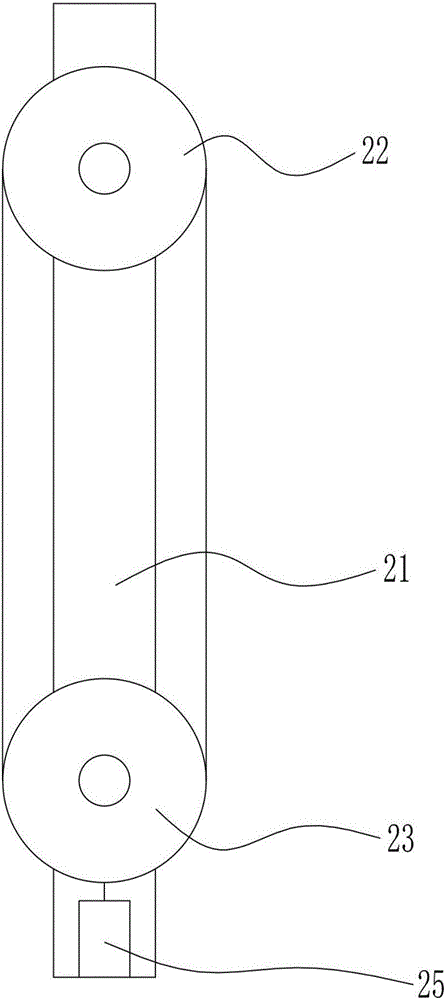

[0026] A cable automatic cutting and binding device, such as Figure 1-Figure 2 As shown, it includes pay-off frame 1, tension control device 3, horizontal guide wheel 4, vertical guide wheel 5, wire guard 6, thread clamp I7, pneumatic cutter 8, thread clamp II9, horizontal guide rail I10, Vertical guide rail 11, guide block 12, manipulator I13, cylinder I14, thread gripper III15, pneumatic turntable 16, winding frame 17, thread gripper IV18, thread gripper V19 and wire binding device 20; the right side of pay-off frame 1 A tension control device 3 is provided, the right side of the tension control device 3 is provided with a horizontal guide wheel 4, the right side of the horizontal guide wheel 4 is provided with a vertical guide wheel 5, the right side of the vertical guide wheel 5 is provided with a wire guard 6, and the wire guard The right side of sleeve 6 is provided with thread gripper I7, the right side of thread gripper I7 is arranged with thread gripper II9, the pneu...

Embodiment 2

[0028] A cable automatic cutting and binding device, such as Figure 1-Figure 6 As shown, it includes pay-off frame 1, tension control device 3, horizontal guide wheel 4, vertical guide wheel 5, wire guard 6, thread clamp I7, pneumatic cutter 8, thread clamp II9, horizontal guide rail I10, Vertical guide rail 11, guide block 12, manipulator I13, cylinder I14, thread gripper III15, pneumatic turntable 16, winding frame 17, thread gripper IV18, thread gripper V19 and wire binding device 20; the right side of pay-off frame 1 A tension control device 3 is provided, the right side of the tension control device 3 is provided with a horizontal guide wheel 4, the right side of the horizontal guide wheel 4 is provided with a vertical guide wheel 5, the right side of the vertical guide wheel 5 is provided with a wire guard 6, and the wire guard The right side of sleeve 6 is provided with thread gripper I7, the right side of thread gripper I7 is arranged with thread gripper II9, the pneu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com