Vehicle body

A body and vehicle technology, applied in the field of vehicles, can solve the problems of single force transmission channel and low force transmission efficiency, and achieve the effects of ensuring living space, reducing the amount of intrusion, and avoiding serious damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

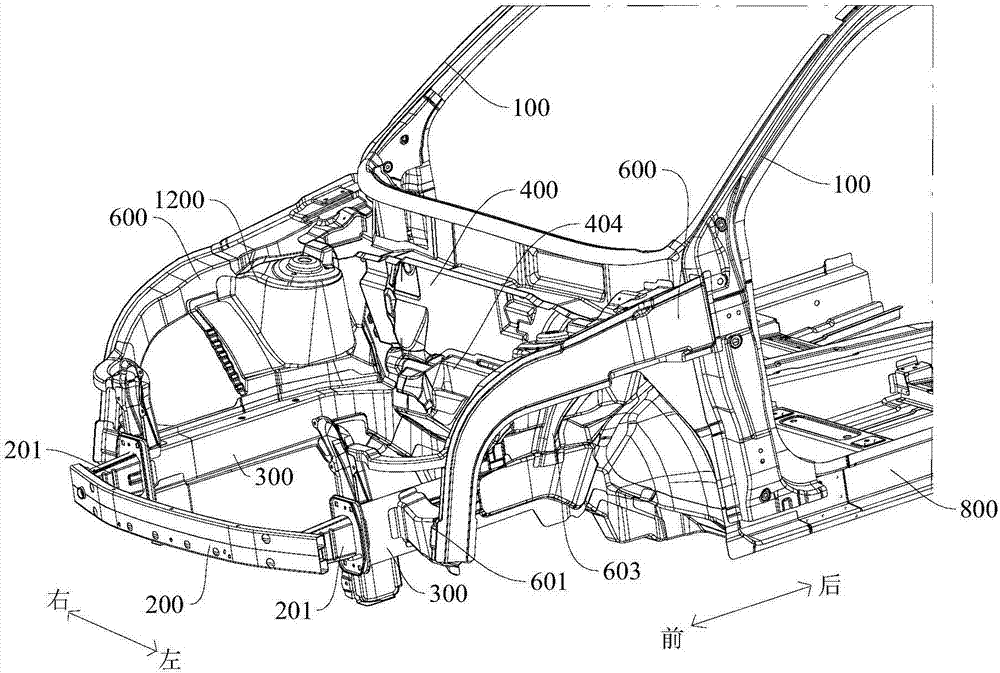

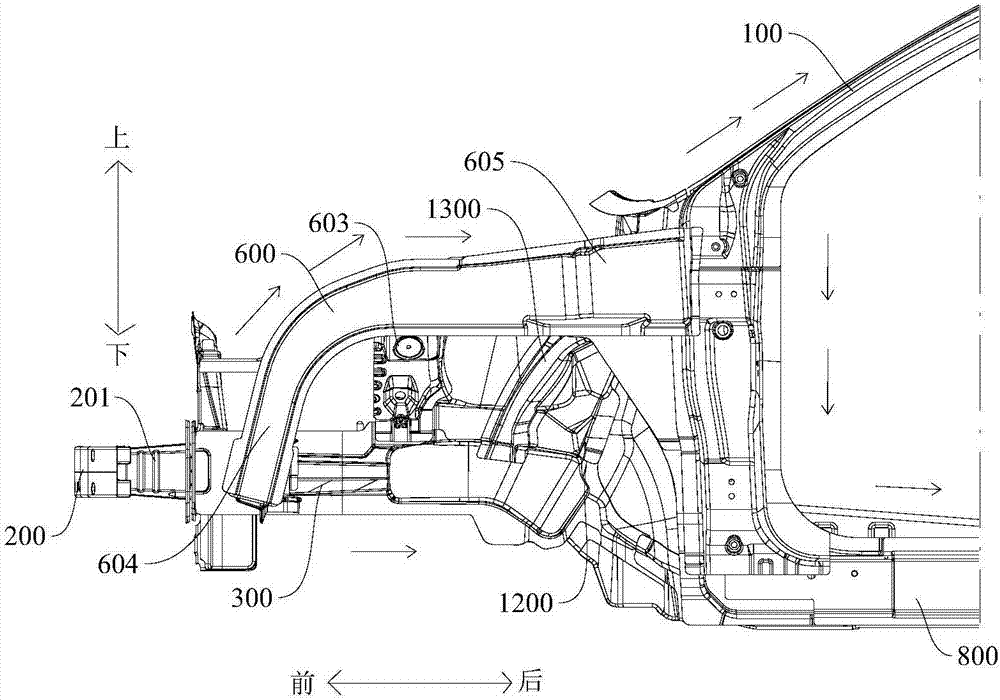

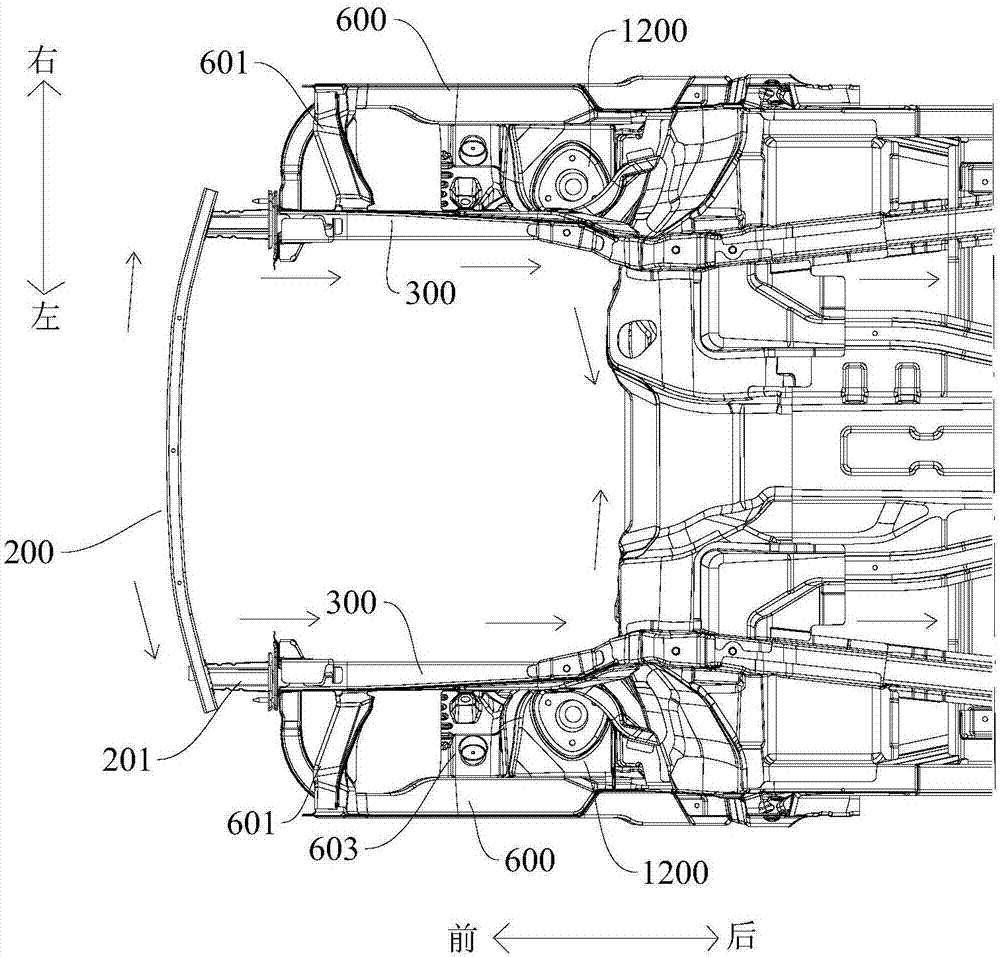

[0065] The following will refer to Figure 1-Figure 23 The vehicle body 10000 of the embodiment of the present invention will be described in detail in conjunction with the embodiments.

[0066] The vehicle body 10000 according to the embodiment of the present invention may include: two A-pillars 100, a front anti-collision beam 200, two front longitudinal beams 300, a dash panel 400, a dash upper cross member 402, a dash lower vertical beam 403 and two The front floor longitudinal beam 500 , of course, the vehicle body 10000 may also include other components, for example, the upper side rail 600 , the door sill beam 800 and the rear floor longitudinal beam 900 and so on.

[0067] Such as figure 1 As shown, the front ends of the two front longitudinal beams 300 are respectively connected to the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com