Method for preparing large-area graphene materials by "stitching method"

A graphene, large-area technology, applied in the field of preparation of large-area graphene materials, can solve problems such as high cost, loss of function, small area, etc., and achieve the effects of prolonging life, low cost, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

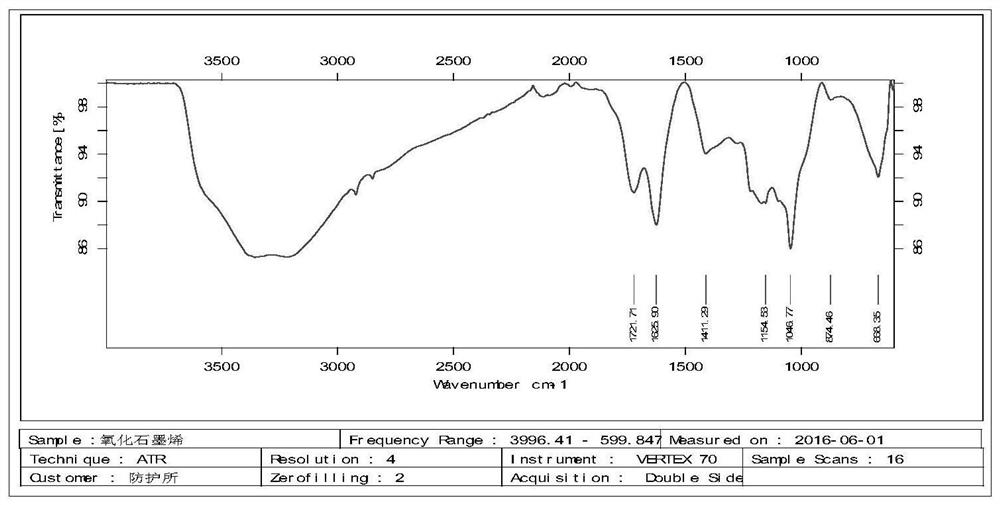

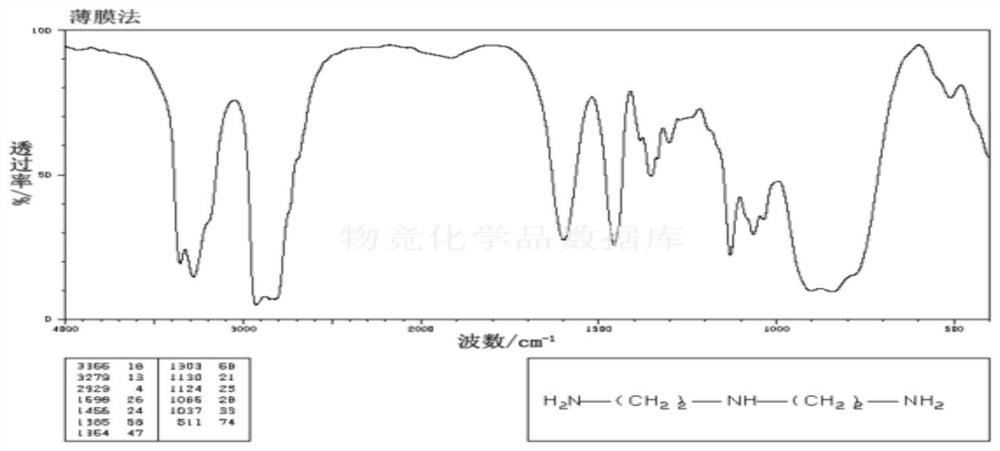

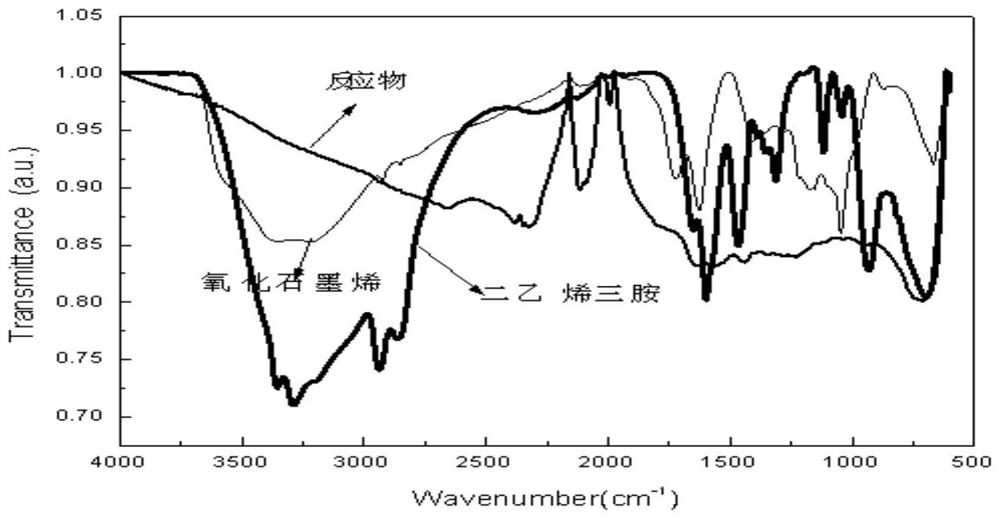

[0021] Graphene oxide GO was added into a conical flask filled with diethylenetriamine at a mass ratio of 1:100. Then use an ultrasonic disperser to disperse for 40 minutes with an ultrasonic intensity of 90%, and observe the dispersion. The solution appeared as a black opaque liquid and dispersed evenly. Immediately moved it into a three-necked flask equipped with a stirring device and a distillation device. While stirring, the temperature was raised, and the reaction temperature was controlled within 120°C. The reaction time was 21 hours. After the reaction, take the reaction solution and apply it evenly on the 20# steel sheet that has been polished and cleaned in advance, cleaned and dried with absolute ethanol, and placed in an oven for 3 hours at 120°C to obtain a graphene film that is "stitched" into a continuous structure .

[0022] The organic amine used as a suture reacts with graphene oxide, and the organic amine with primary amines at both ends reacts with graphene...

Embodiment 2

[0031] Add graphene oxide GO into the Erlenmeyer flask filled with ethylenediamine at a mass ratio of 1:200. Then use an ultrasonic disperser to disperse for 60 minutes with an ultrasonic intensity of 90%, and observe the dispersion. After being uniformly dispersed, immediately transfer it to a three-necked flask equipped with a stirring device and a distillation device. Under stirring, raise the temperature, control the reaction temperature within 140°C, and the reaction time is 21 hours. After the reaction, take the reaction solution and apply it evenly on the 20# steel sheet that has been polished and cleaned in advance, cleaned and dried with absolute ethanol, and placed in an oven for 3 hours at 120°C to obtain a graphene film that is "stitched" into a continuous structure .

Embodiment 3

[0033] Add graphene oxide GO into the Erlenmeyer flask filled with diethylenetriamine at a mass ratio of 1:400. Then use an ultrasonic disperser to disperse for 55 minutes with an ultrasonic intensity of 90%, and observe the dispersion. Immediately after the dispersion is uniform, move it into a three-neck flask equipped with a stirring device and a distillation device. While stirring, raise the temperature and control the reaction temperature within 100-200°C, and the reaction time is 23h. After the reaction, take the reaction solution and apply it evenly on the 20# steel sheet that has been polished and cleaned in advance, cleaned and dried with absolute ethanol, and placed in an oven for 3 hours at 120°C to obtain a graphene film that is "stitched" into a continuous structure .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com