Antifriction heat-conducting lubricating grease for motor bearings of pure electric vehicles

A pure electric vehicle, motor bearing technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of pure electric vehicle maintenance and use costs, large thermal load of motor bearings, shortened service life of bearings, etc., to reduce friction coefficient, heat load reduction, and operating temperature reduction effects

Inactive Publication Date: 2018-05-08

SHANDONG NORTH ZITE SPECIAL OIL

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

With the development of pure electric vehicles in the direction of high speed, small size and heavy load, the thermal load that the motor bearing needs to bear is increasing, which leads to the long-term work of the bearing at high temperature, which eventually leads to a greatly shortened service life of the bearing. The maintenance of pure electric vehicles and usage costs continue to increase

[0003] However, the thermal load problem of pure electric vehicle motor bearings has not attracted the attention of pure electric vehicle manufacturers and lubricant material researchers. Lubricating grease to meet the requirements of new grease for the development of pure electric vehicles

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

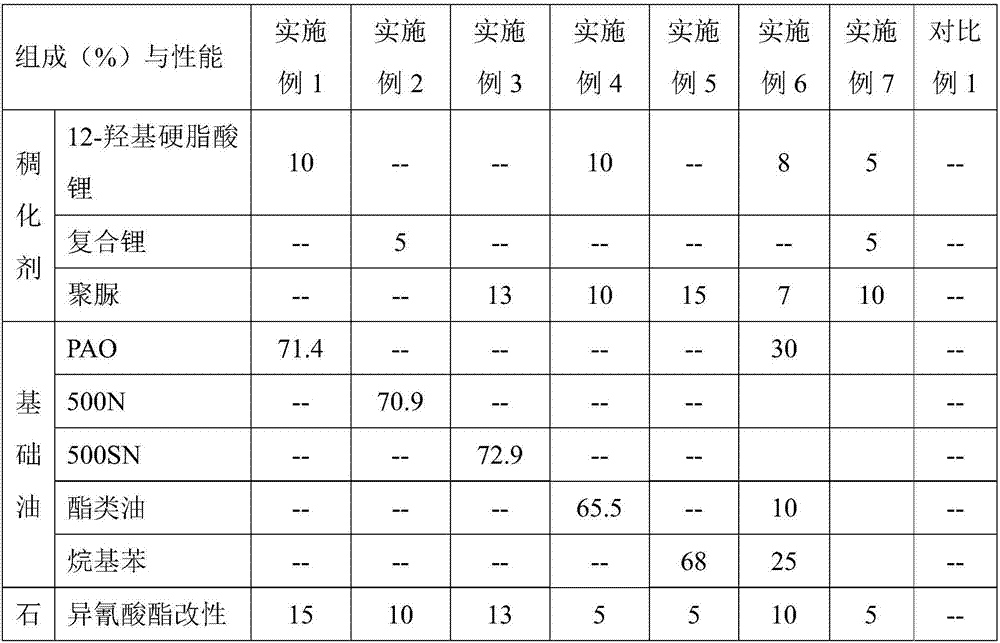

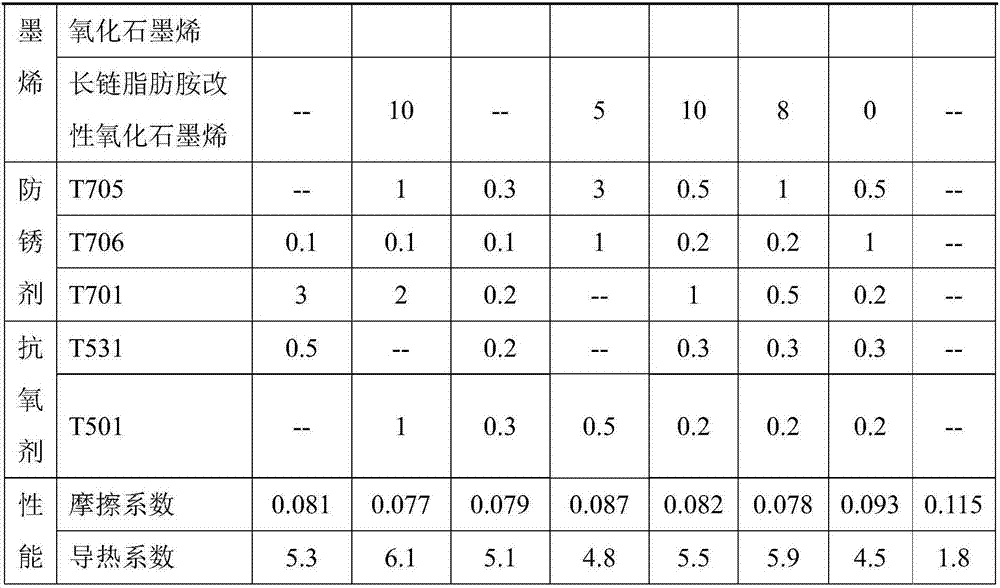

Embodiment 1-7

[0027] The proportioning and performance of embodiment 1-7 and comparative example 1 are shown in table 1

[0028] The performance analysis of table 1 embodiment 1-7 and comparative example 1

[0029]

[0030]

[0031] Note: The unit of thermal conductivity is W / (m.K)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an antifriction heat-conducting lubricating grease for motor bearings of pure electric vehicles. The lubricating grease is prepared from, by weight, 65-85% of base oil, 5-20%of thickener, 0.1-5% of antioxidant, 0.1-5% of rust and corrosion inhibitor, and 5-20% of modified graphite. The lubricating grease has the advantages of friction reduction, energy conservation, excellent heat conductivity and the like. The product meets the lubricating requirements of high-rotating-speed, high-temperature, high-load and extremely-low-temperature motor bearings of pure electric vehicles, significantly reduces the friction coefficient of motor bearings and saves electric energy; meanwhile, the product has great heat conductivity, so that the running temperature of bearings is greatly reduced, and accordingly the service life of bearings is prolonged.

Description

technical field [0001] The invention relates to the field of lubricants, in particular to a friction-reducing and heat-conducting lubricating grease for motor bearings of pure electric vehicles. Background technique [0002] A pure electric vehicle is a vehicle driven by a motor, and the main friction part of the motor is the motor bearing. With the development of pure electric vehicles in the direction of high speed, small size and heavy load, the thermal load that the motor bearing needs to bear is increasing, which leads to the long-term work of the bearing at high temperature, which eventually leads to a greatly shortened service life of the bearing. The maintenance of pure electric vehicles and usage costs continue to increase. [0003] However, the thermal load problem of pure electric vehicle motor bearings has not attracted the attention of pure electric vehicle manufacturers and lubricant material researchers. Lubricating grease meets the requirements of new type ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10N30/06C10N30/08C10N40/02C10N50/10

CPCC10M169/048C10M2201/14C10M2203/065C10M2203/1025C10M2205/0285C10M2207/026C10M2207/127C10M2207/128C10M2215/065C10M2215/223C10M2217/045C10M2219/044C10N2030/06C10N2030/08C10N2040/02C10N2050/10C10N2020/02C10N2010/02C10N2010/04

Inventor 冯克权王秀东杨庆超董慧美杨闻焕王春艳

Owner SHANDONG NORTH ZITE SPECIAL OIL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com