Light transmitting brick and preparation method thereof

A technology of light-transmitting bricks and bricks, which is applied in the field of optical fibers, can solve the problems that light-transmitting bricks are easily squeezed and deformed, optical fibers and bricks are easy to fall off or loosen, and achieve the effect of increasing strength and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

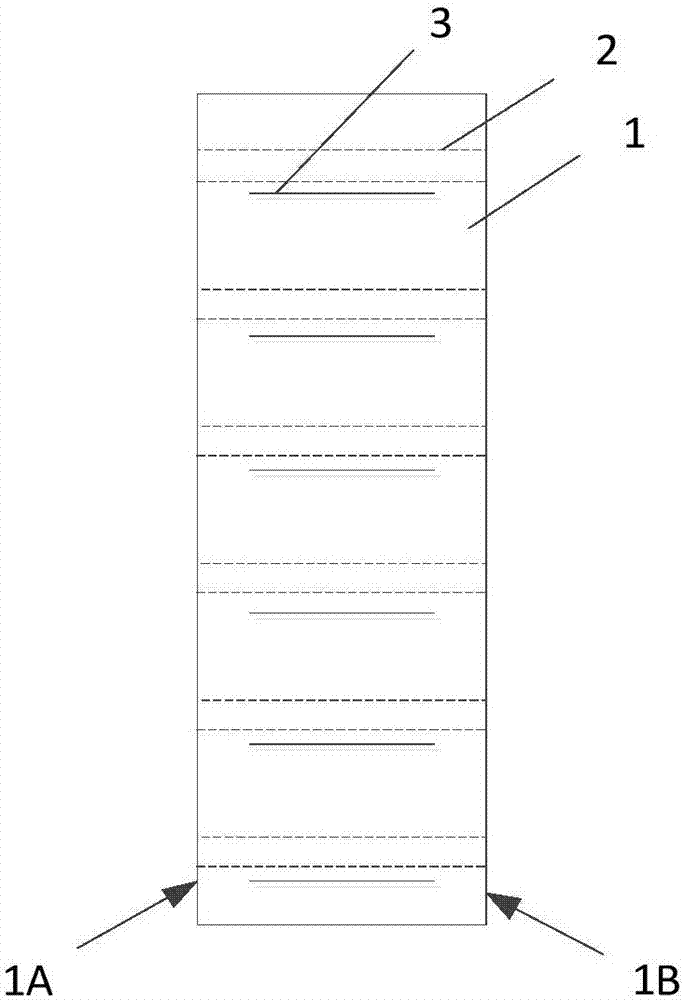

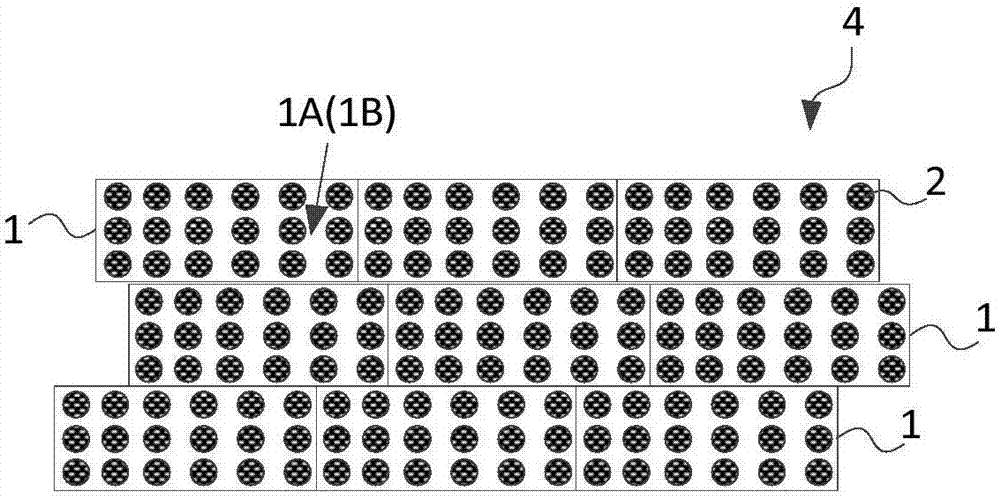

[0026] See figure 1 , is a schematic diagram of a top-view structural principle of a light-transmitting brick in an embodiment of the present invention.

[0027] like figure 1 As shown, the light-transmitting brick includes a brick body 1 and one or more light-transmitting components 2, and the two sides of the brick body 1 that are not adjacent to other brick bodies 1 or walls are respectively defined as the first side 1A and the second side 1B, the light-transmitting components 2 are distributed in the brick body 1, one end of each of the light-transmitting components 2 is located on the first side 1A, and the other end is located on the second side 1B, wherein each light-transmitting component 2 has at least A reinforcing rib 3 is connected / each of the light-transmitting parts is connected with at least one reinforcing rib 3 , and the reinforcing rib is arranged in the brick body 1 .

[0028] By connecting reinforcing ribs on the light-transmitting part, the strength of t...

Embodiment approach 1

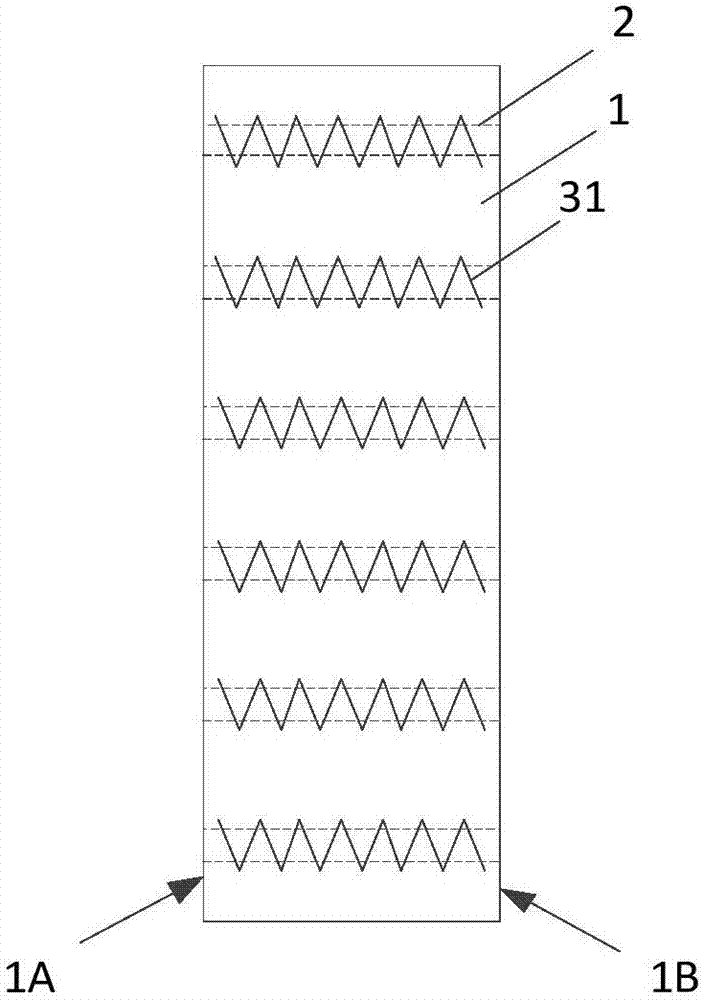

[0032] See image 3 , is a schematic diagram of an implementation principle of the structure of the light-transmitting part and the reinforcing rib in the light-transmitting brick of the present invention. As shown in the figure, the reinforcing rib 3 can be a wire body 31 wound and connected with the light-transmitting part 2 . Wherein, the wire body 31 may be iron wire, copper wire, aluminum wire, cotton wire and the like. In specific implementation, iron wire may be preferred.

Embodiment approach 2

[0034] See Figure 4 , is a schematic diagram of another implementation principle of the structure of the light-transmitting part and the reinforcing rib in the light-transmitting brick of the present invention. As shown in the figure, the reinforcing rib 3 can be a tube body 32 that passes through or covers the light-transmitting part 2 . Wherein, the pipe body 32 may be a steel pipe or a plastic pipe.

[0035] Specifically, see Figure 5 ,for Figure 4 A structural schematic diagram of an implementation of the middle tube body, as shown in the figure, the tube body 32 can be a fastener that can be opened and closed freely. The fastener can have such a structure: one end of the fastener is hinged to realize relative free rotation, and the other end is freely connected to realize free opening and closing connection (that is, it can be freely opened and closed in the K direction or in the opposite direction). When it is on the light-transmitting part, the light-transmitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com