High-strength self-locking structure

A self-locking structure, high-strength technology, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problem that expansion screws cannot achieve high-strength fixation, and achieve the effect of facilitating secondary installation and reversible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

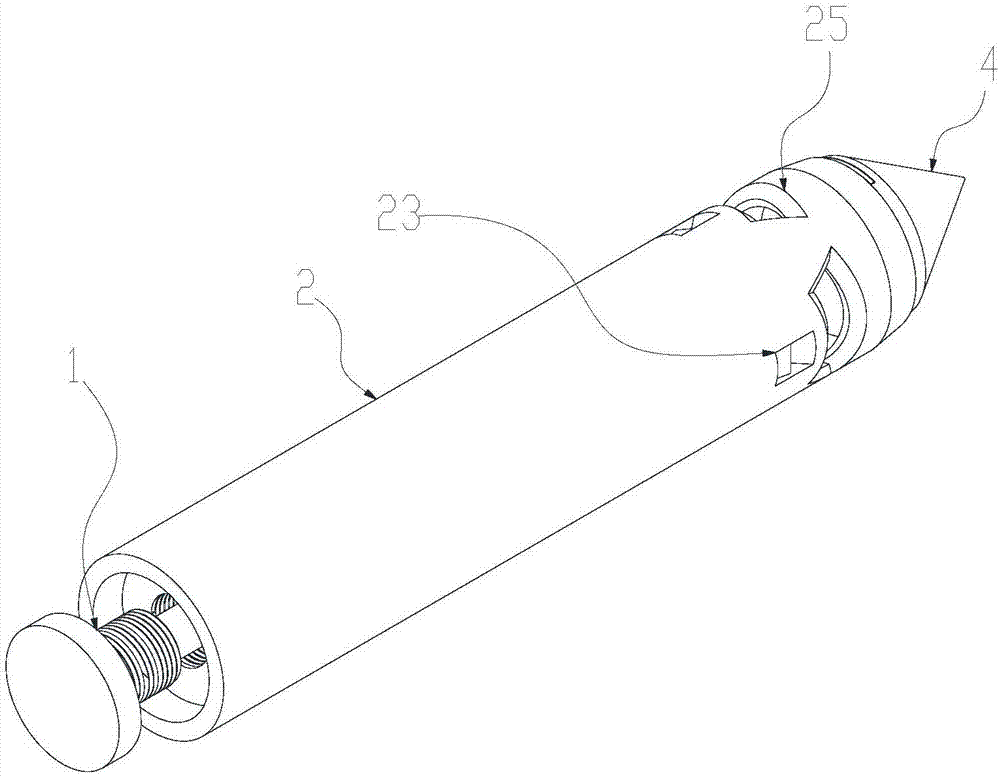

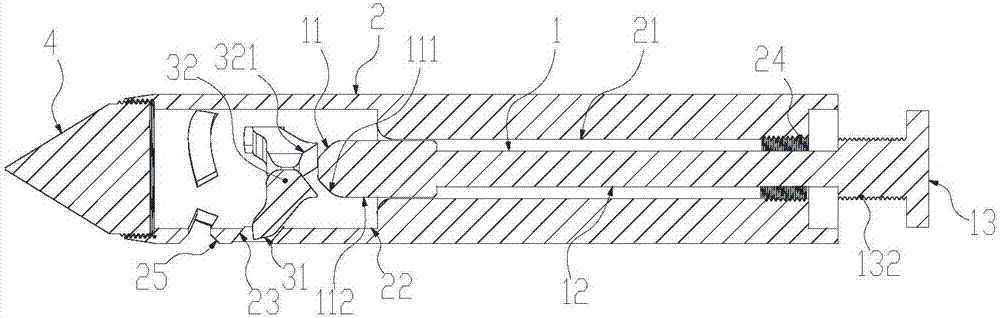

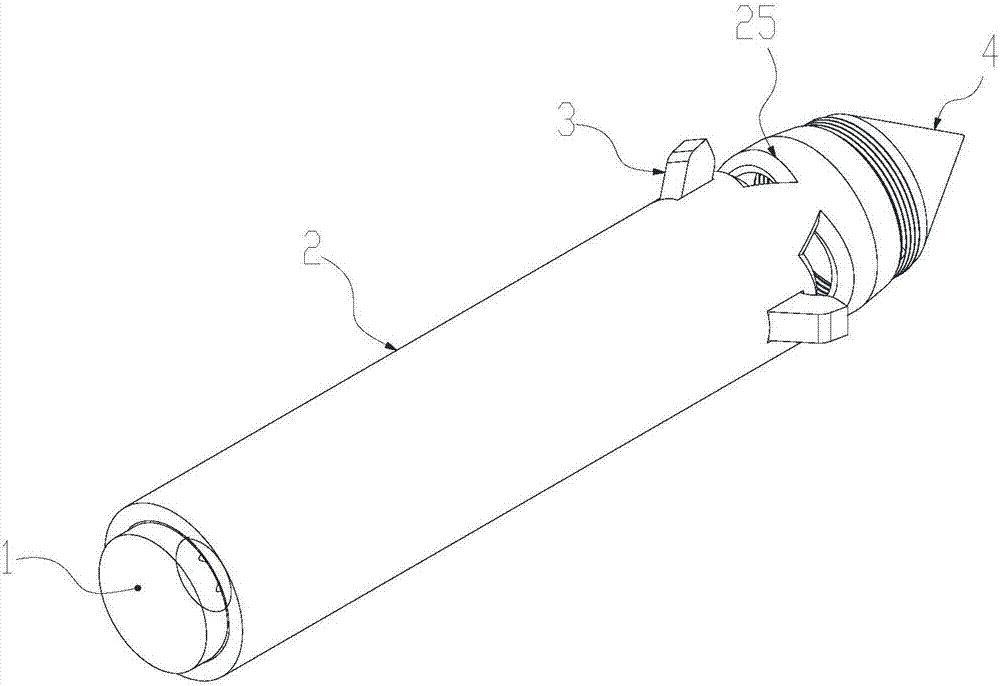

[0028] like Figure 1~4 The shown high-strength self-locking structure includes a fixed push rod 1, a fixed cylinder 2 and a fixed lock 3, and the fixed cylinder 2 is respectively provided with a fixed slideway 21, a lock chamber 22 and a lock through hole 23 . There are one or more fixed latches 3 mentioned above. The number of the lock through holes 23 matches the fixed lock 3, the fixed lock 3 is divided into a self-tapping part 31 and a fixed tail 32, the self-tapping part 31 is placed in the lock through hole 23, and the fixed tail 32 Placed in the locking chamber 22 , the outer diameter of the fixed tail portion 32 is larger than the inner diameter of the locking through hole 23 , and the outer diameter of the self-tapping portion 31 is smaller than the inner diameter of the locking through hole 13 . The above-mentioned fixed propulsion rod 1 is movably socketed in the fixed slideway 11 .

[0029] In order to ensure that the fixed buckle 3 can firmly form a tight fit ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap