Spiral belt winding guide concentric launching cylinder

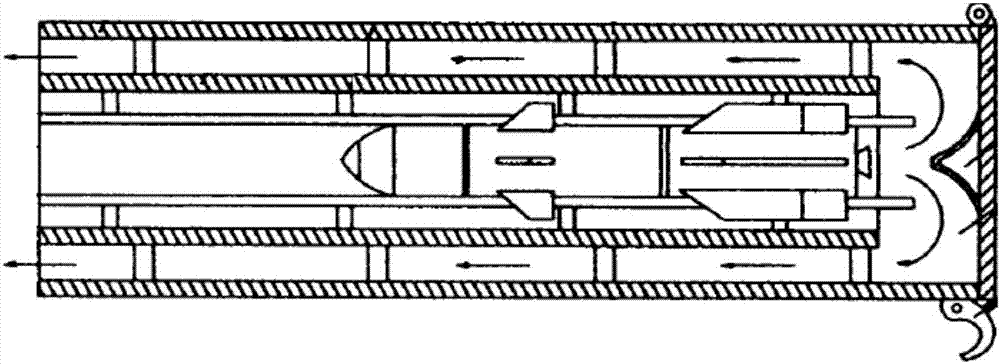

A launch tube and screw technology, which is applied in the field of space launch, can solve the problems affecting the safety of missile launch and the temperature rise of the missile wall, and achieve the effects of easy popularization, improvement of pressure and simple principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

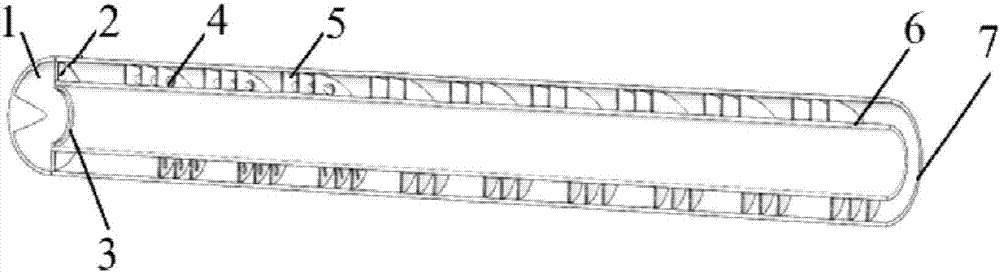

[0035] combine figure 2 , a helically wound tape-guiding concentric launching tube of the present embodiment, comprising an inner tube 6, an outer tube 7 and a diversion cone 1, the inner tube 6 and the outer tube 7 are arranged coaxially, and the diversion cone 1 is fixedly connected to the outer tube 7 ends. The annular cavity between the inner cylinder 6 and the outer cylinder 7 is used for exhausting combustion exhaust gas, and a spiral winding belt 5 surrounds the annular cavity, so that the gas entering the annular cavity after passing through the diversion cone 1 is discharged around the spiral cavity. The spiral winding belt 5 circles along the inner cylinder 6, separates the annular cavity, and forms a spiral cavity. The pitch of the helical winding belt 5 can be adjusted according to the minimum fluid resistance.

[0036] With one end close to the diversion cone 1 as the bottom end and the other end as the outer end, a spiral winding belt 5 wraps around from the b...

Embodiment 2

[0046]The basic structure of the spiral-wound flow-guiding concentric launching tube of this embodiment is the same as that of Embodiment 1, and the improvement is that there are two spiral-wound belts 5, and the pitches of each helically-wound belt 5 are the same, and the spiral-wound belts 5 have the same pitch. The distance between the end of the belt 5 close to the diversion cone 1 and the end of the inner cylinder 6 is 2 times the pitch, so that the gas can quickly enter the annular cavity at the entrance, and the lower end point of the spiral winding belt 5 is flush, and the same vertical On the cross-section of the axis, so that the gas can enter each cavity at the same time.

[0047] As a preferred solution, the two helical belts 5 can be distributed at equal intervals in the circumferential direction to form two helical chambers, and the exhaust gas is discharged around the helical chambers. The distance between the top of the spiral winding belt 5 and the top of the ...

Embodiment 3

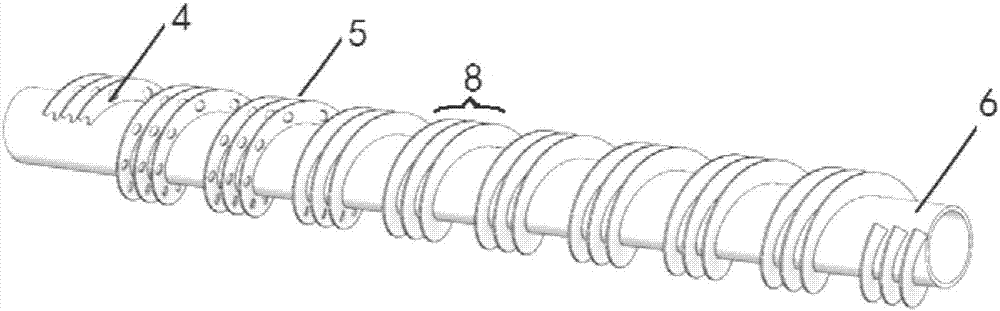

[0050] to combine image 3 , a kind of helical-wound flow-guiding concentric launching tube of this embodiment, its basic structure is the same as that of embodiment 2, the improvement is that: in this embodiment, three helical-wound belts 5 are arranged, and the helically-wound belts 5 are adjacent to Arranged to form a helical winding body 8, the pitch of the helical winding body 8 is the same as that of the helical winding belt 5. But the difference is that a small spiral cavity is formed between the spiral winding strips 5 in the spiral winding body 8 , while the spiral winding body 8 as a whole has a larger spiral cavity.

[0051] In this embodiment, the distance between the helical winding belt 5 and the end of the inner cylinder 6 is a single pitch, and the distance between the top of the helical winding belt 5 and the top of the inner cylinder 6 is 20 mm. In this embodiment, the number of support plates 2 can be set to 3 as a preference, and 3 The support plates 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com