An absolute grating ruler and displacement measuring method

A grating scale and absolute technology, applied in the field of optical measurement, can solve the problems of long signal processing time period, affecting the quality of machining, and low response speed, etc., to reduce signal processing time, improve measurement response speed, and short time period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

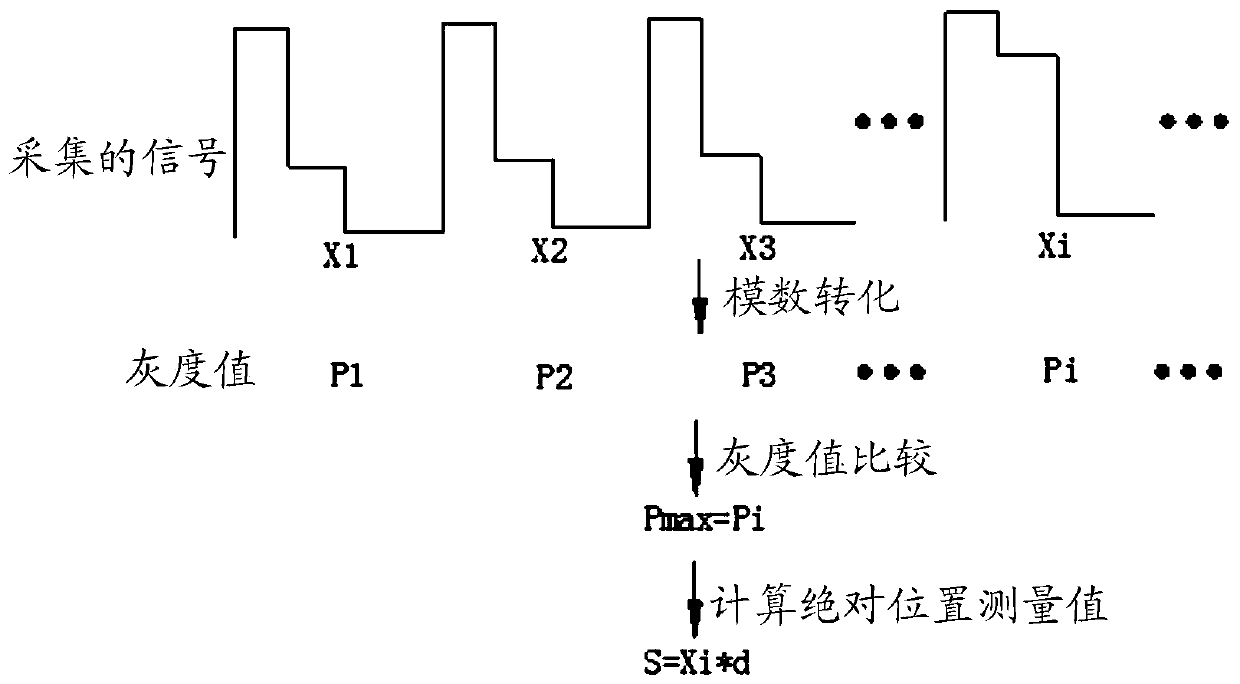

[0079] Preferably, in a specific implementation manner, the specific process of calculating the absolute position measurement value of the target spot according to the position value of the target photosensitive element may include:

[0080] Obtain the photosensitive element pixel center distance of the image sensor array;

[0081] The absolute position measurement of the target spot is calculated according to the following formula:

[0082] s=x i *d;

[0083] In the formula, s is the absolute position measurement value of the target spot; d is the photosensitive element pixel center distance; x i is the position value of the target photosensitive element.

[0084] The displacement measurement method described in the embodiment of the present invention can be realized according to the functions of each functional module of the above-mentioned absolute grating scale, and its specific realization process can refer to the relevant description of the above-mentioned embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com