Cable measurement device

A measuring device and cable technology, applied in measuring devices, instruments, etc., can solve problems such as inflexible operation, inaccurate measurement, and difficulty in finding cable problems, so as to prevent inaccurate measurement, stable and accurate measurement, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

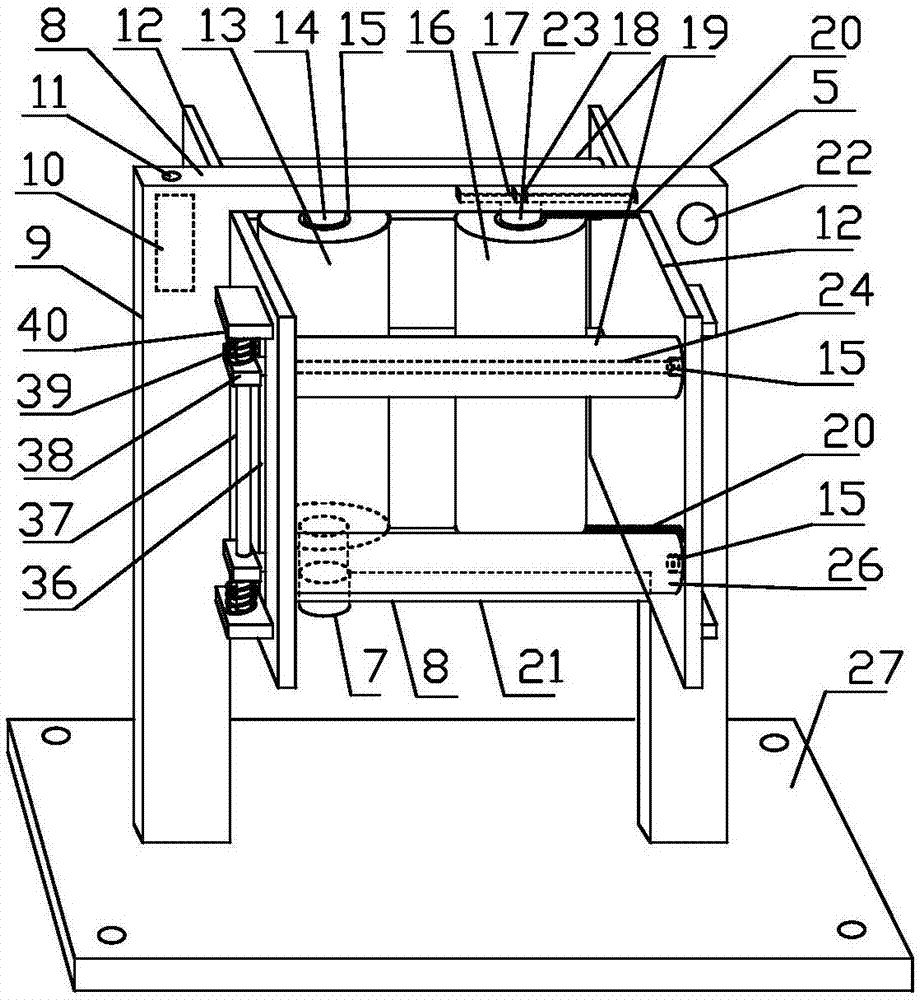

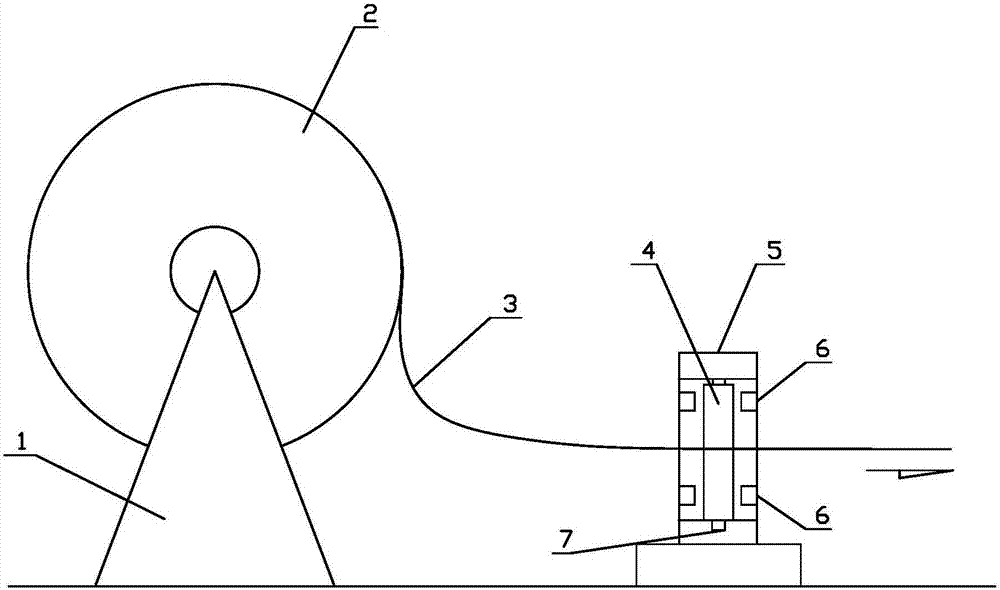

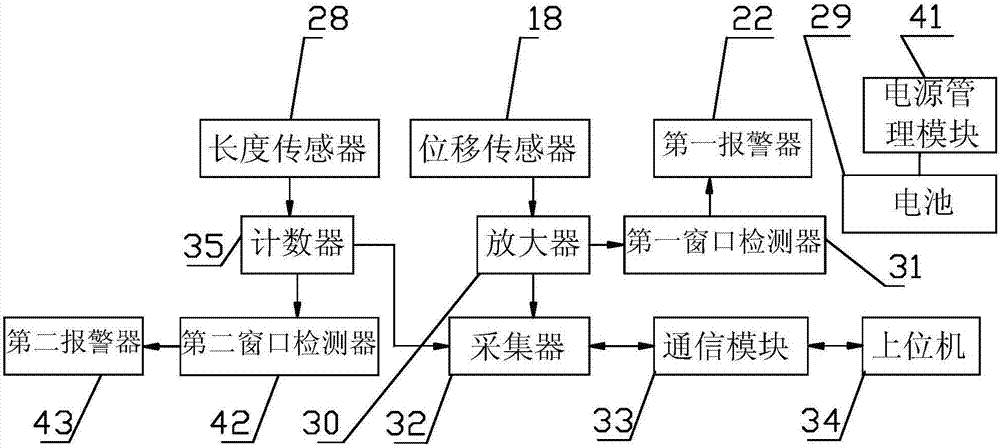

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 The cable measuring device shown in is used for real-time length and wire diameter measurement of the cable when it is released from the cable drum at the construction site.

[0024] Such as figure 1 The cable measuring device is provided with a horizontal base, and an outer frame 9 fixed to the base 27, and the outer frame 9 is provided with a fixed rod 8 for connecting a pair of rollers. The outer frame is provided with a fixed roller 13 and a measuring roller 16 vertically arranged with the fixed rod. The direction setting of fixed bar 13 and measuring roller 16 is not limited, only need to be stably fixed with outer frame, or become a part of outer frame 9, as an embodiment in figure 1 , 2 Adopt the fixed rod that horizontally arranges in the middle, and fixed rod 8 is set to a pair of high and low positions, is respectively referred to as top rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com