Defect elimination guidance-based spare part management system and terminal device

A technology of spare parts and management system, which is applied in the field of spare parts management system and terminal equipment based on the elimination of defects, can solve the problems that affect the efficiency of defect elimination processing, cannot know the quantity of spare parts, and cannot provide defect elimination guidance, etc., to achieve The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The spare parts management system based on the elimination of defects in the embodiment of the present invention is based on the mysql platform and implemented by using the JAVA language and the LINUX language.

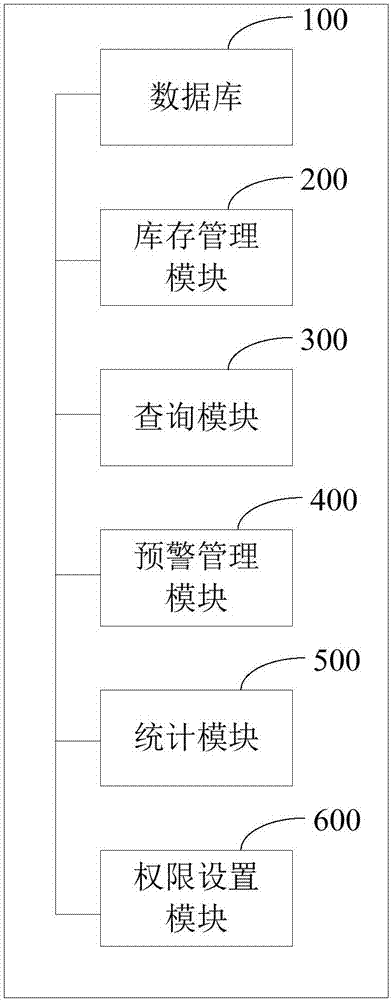

[0040] figure 1 It shows a schematic diagram of the structure of the spare parts management system based on the elimination of defects, and the details are as follows:

[0041] The spare parts management system based on defect elimination orientation in this embodiment includes: a database 100 , an inventory management module 200 , a query module 300 , an early warning management module 400 , a statistics module 500 and an authority setting module 600 .

[0042] The database 100 is used to store the basic information of spare parts, equipment defect information and defect elimination guidance information corresponding to the equipment defect information, and provide the query module 300 with equipment defect information and corresponding defect elimination guid...

Embodiment 2

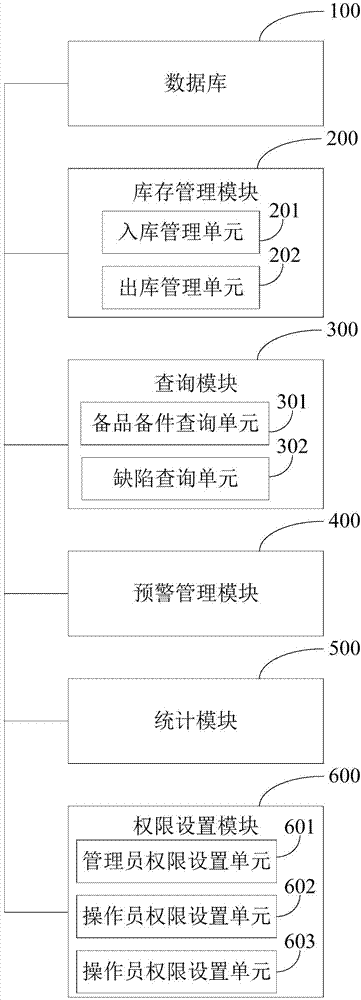

[0050] figure 2 It shows another structural diagram of spare parts management system based on defect elimination orientation, which is described in detail as follows:

[0051] The spare parts management system based on defect elimination orientation in this embodiment includes: a database 100 , an inventory management module 200 , a query module 300 , an early warning management module 400 , a statistics module 500 and an authority setting module 600 .

[0052] The database 100 is used to store the basic information of spare parts, equipment defect information and defect elimination guidance information corresponding to the equipment defect information, and provide the query module 300 with the basic information of spare parts, equipment defect information and corresponding defect elimination guidance information.

[0053] The inventory management module 200 is used to record the basic information of spare parts entering the warehouse and spare parts leaving the warehouse. ...

Embodiment 3

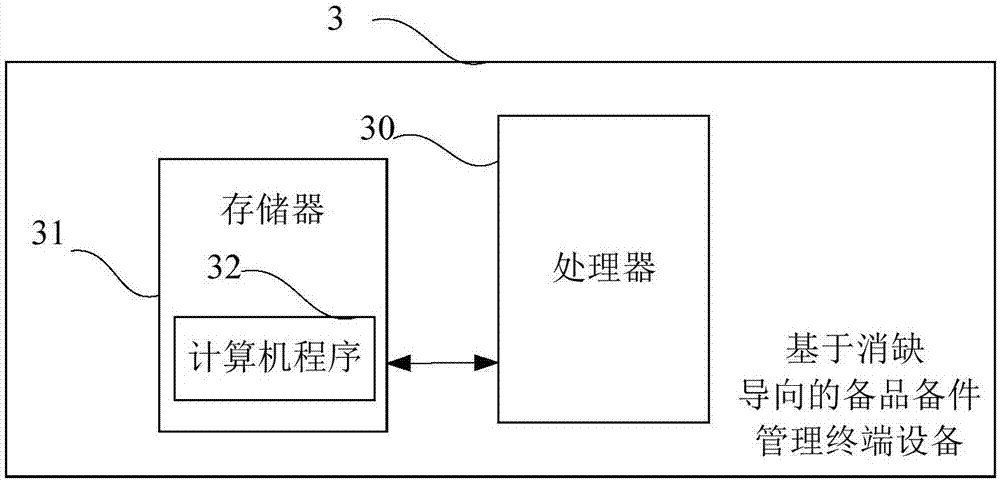

[0088] image 3 It is a schematic diagram of a spare parts management terminal device based on defect elimination guidance provided by an embodiment of the present invention. like image 3 As shown, the spare parts management terminal device 3 based on the defect elimination guide of this embodiment includes: a processor 30, a memory 31, and a computer program 32 stored in the memory 31 and operable on the processor 30, for example, using The artificial neural network is used to carry out the program of spare parts data statistics. When the processor 30 executes the computer program 32, it realizes the functions of each module / unit in the above-mentioned device embodiments, for example figure 1 The functions of modules 100 to 600 are shown.

[0089] Exemplarily, the computer program 32 can be divided into one or more modules / units, and the one or more modules / units are stored in the memory 31 and executed by the processor 30 to complete this invention. The one or more mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com