a boost sb 2 te 3 Methods for thermoelectric properties of base materials

A thermoelectric performance and base material technology, which is applied in the field of improving the thermoelectric performance of Sb2Te3 base materials, can solve the problems that the performance and process cannot meet the actual application requirements, and achieve the effects of optimizing electrical transmission performance, improving thermoelectric performance, and enhancing phonon scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A raised Sb 2 Te 3 The method for the thermoelectric performance of the base material, the specific steps are as follows:

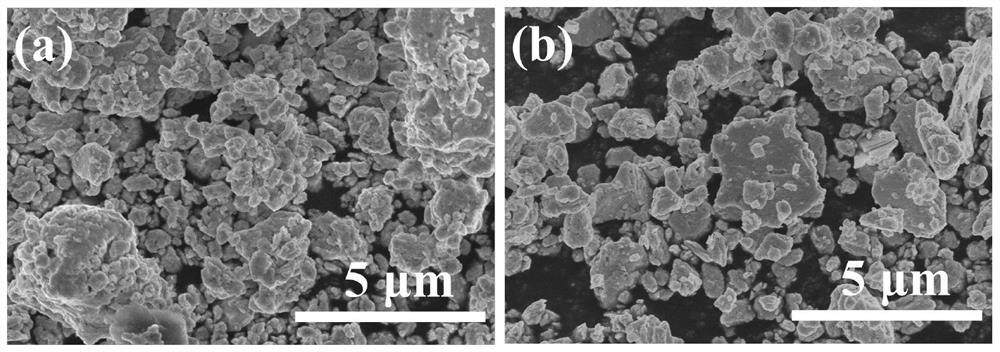

[0037] (1) Bi 2 Te 3 , Sb 2 Te 3 The ingot is crushed into particles with a particle size of 2 to 5mm; then it is vacuum ball-milled on a planetary ball mill to form a powder with a particle size of several hundred nanometers to several microns, and the shape is as follows image 3 shown;

[0038] Among them, the ball milling process on the planetary ball mill is as follows: the ball-to-material ratio is 8:1, the speed is 450rpm, and the speed ratio is 2:1. Both the grinding pot and the balls are A-grade agate. -0.5MPa.

[0039] Bi 2 Te 3 , Sb 2 Te 3 The ingot preparation method is as follows:

[0040] According to Bi 2 Te 3 , Sb 2 Te 3 Stoichiometric ratio Weigh 30g of Bi, Te, Sb pure component particles in a ceramic crucible, and cover 5gB 2 o 3 Protect; prepare Bi by melting in SK2 type box-type resistance furnace 2 Te 3 , Sb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap