Power cable connecting joint

A technology for connecting joints and power cables, which is applied to the connection, parts of the connection device, and the connection where permanent deformation plays a role, etc. It can solve the problems of safety threats to ground operators, weak grip of the wrench, and poor use effect. Achieve the effect of simple structure, good use effect and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

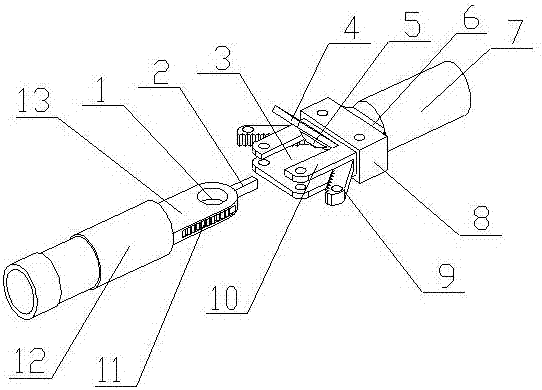

[0022] A power cable connection joint of the present invention is realized in this way. When in use, during power construction, the connection end of one of the cables is first stripped and then put into the main connection sleeve (7), and the connection end of the other cable is stripped. Then put it into the auxiliary connecting sleeve (12), then use the crimping nose pliers to press and fix it respectively, and then insert the connecting piece (13) between the limit plate (10) and the support plate (3), and the connecting piece ( 13) Drive the limit rod (2) to move into the strip groove on the connecting plate (6), and then rotate the two clamping plates (9) so that the two clamping plates (9) are clamped on the connecting piece (13) respectively On both sides of the connecting piece (13), the locking teeth (11) on the two card plates (9) are respectively clamped and fixed with the locking teeth (11) on both sides of the connecting piece (13), so as to fix both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com