Gas-liquid photoelectric combined slip ring

A technology of photoelectric combination and conductive slip ring, which is applied in the field of communication, can solve the problems that the slip rings are difficult to combine together, and achieve the effect of improving the efficiency of use and changing the way of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

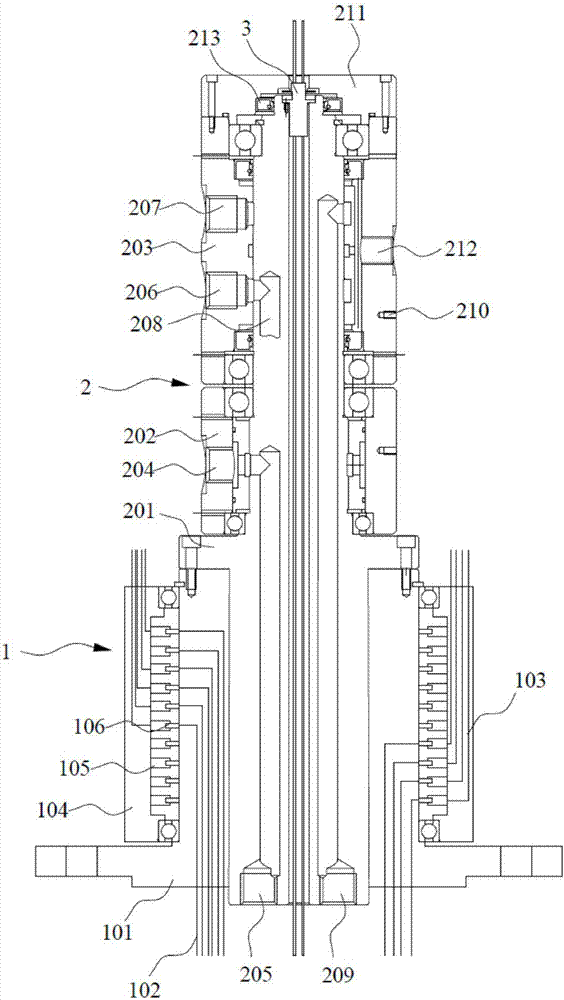

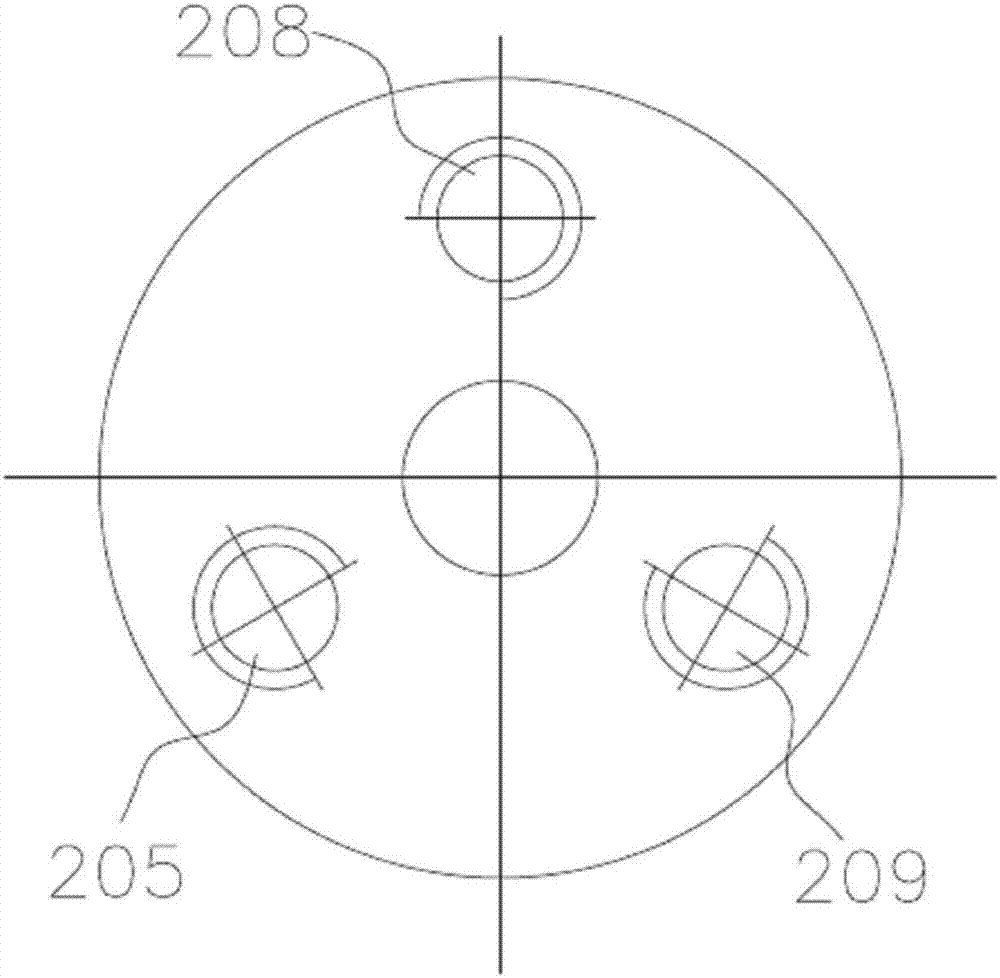

[0022] like Figure 1-Figure 2 As shown, this embodiment provides an air-liquid photoelectric combination slip ring, including a conductive slip ring module 1, an air-liquid slip ring module 2, and an optical fiber slip ring 3; the conductive slip ring module 1 is located at the forefront of the entire device, and it includes The conductive slip ring shaft 101, the rotor cable 102, the stator cable 103 and the conductive slip ring housing 104, the conductive slip ring housing 104 is sleeved on the conductive slip ring shaft 101, and the inside of the conductive slip ring housing 104 is provided with a carbon brush holder 105 , and the carbon brush ring 106 is also fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com