Precision forging die structure facilitating forging

A technology for precision forgings and molds, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc. It can solve the problems of inability to realize forging demoulding, limited mold closing height, and inability to carry out precision forgings, etc. , to achieve the effect of convenient and quick separation, improved quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

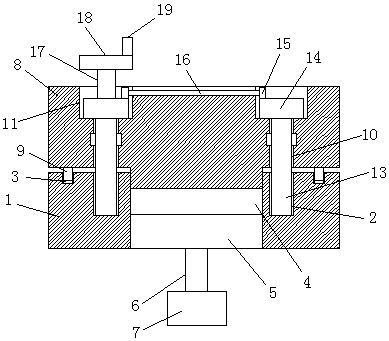

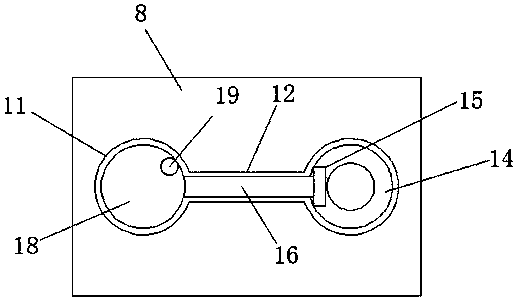

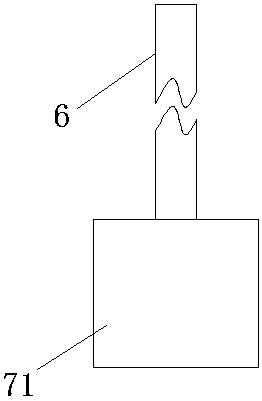

[0020] A die structure for precision forgings that is convenient for forging, including a lower die 1, threaded blind holes 2 are provided on the center of both ends of the lower die 1, guide holes 3 are provided on the outside of the threaded blind holes 2, and the center of the lower die 1 A mold cavity 4 is provided, and a lower mold core plate 5 used in conjunction with the mold cavity 4 is provided. The bottom surface of the lower mold core plate 5 is provided with a lifting rod 6, and the other end of the lifting rod 6 is connected to a power device 7. The power unit 7 includes a cylinder 71 controlled by a manual switch. The output end of the cylinder 71 is connected with a lifting rod 6, which is convenient for the lower mold core plate 5 to be ejected upwards or pulled downwards. The top surface of the lower mold 1 is provided with a The upper mold 8, the bottom surface of the upper mold 8 is respectively provided with a guide post 9 and a threaded through hole 10, the...

Embodiment 2

[0022] A die structure for precision forgings that is convenient for forging, including a lower die 1, threaded blind holes 2 are provided on the center of both ends of the lower die 1, guide holes 3 are provided on the outside of the threaded blind holes 2, and the center of the lower die 1 A mold cavity 4 is provided, and a lower mold core plate 5 used in conjunction with the mold cavity 4 is provided. The bottom surface of the lower mold core plate 5 is provided with a lifting rod 6, and the other end of the lifting rod 6 is connected to a power device 7. The power unit 7 comprises a stepping motor 72 controlled by a manual switch, the output end of the stepping motor 72 is provided with a screw mandrel 73, the screw mandrel 73 is provided with a sliding block 74, and the other end of the sliding block 74 is provided with a lifting rod 6, It is convenient to push out or pull down the core plate 5 of the lower mold. The top surface of the lower mold 1 is provided with an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com