Silk spooler

A technology of winding machine and silk material, which is applied in the direction of spinning machine, continuous winding spinning machine, textile and paper making, etc. It can solve the problems that the winding cannot be guaranteed evenly and the silk is easy to break, so as to reduce the broken thread, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

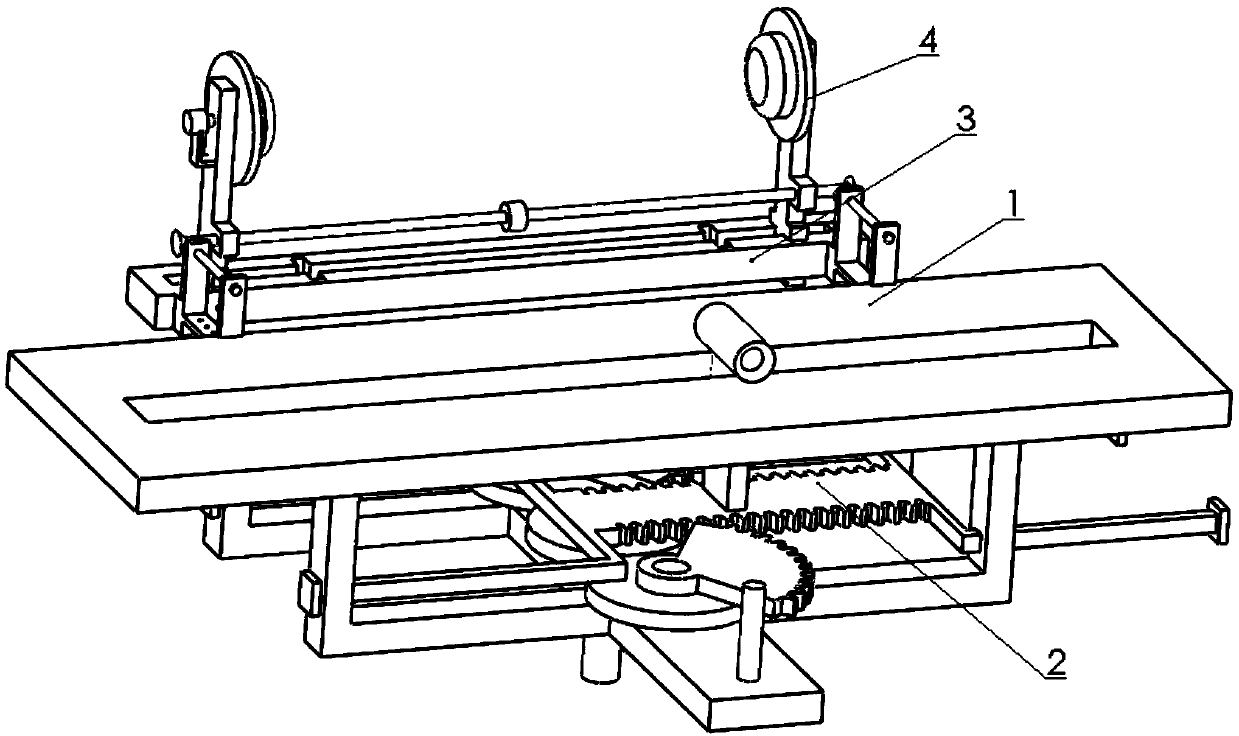

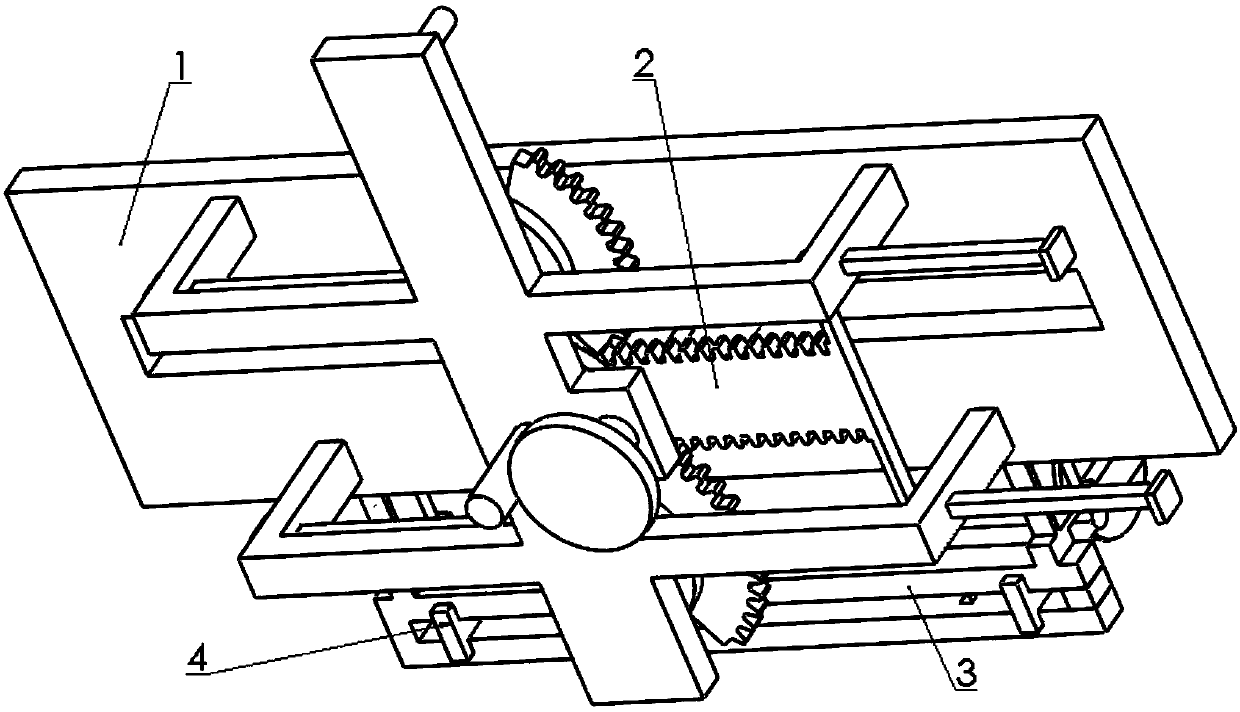

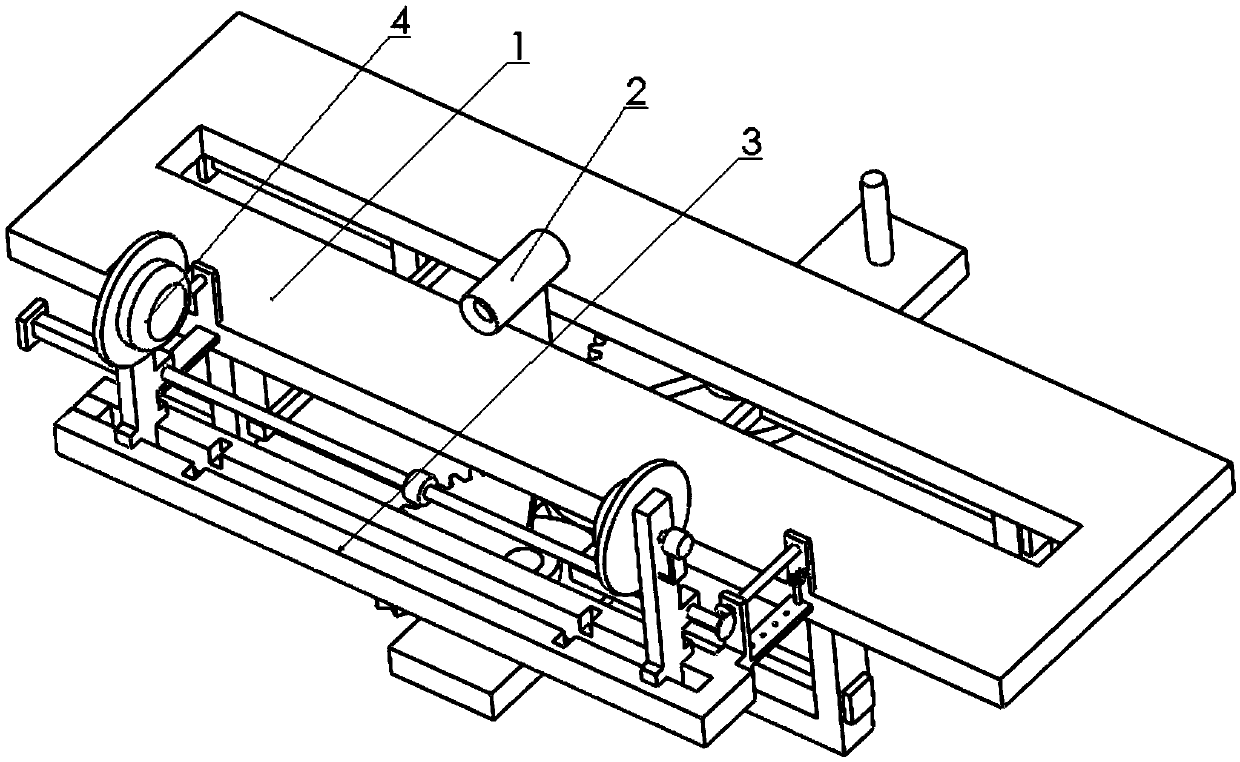

[0026] Combine below Figure 1-11 Describe this embodiment, the present invention relates to the technical field of textile production, more specifically a silk winding machine, comprising a reciprocating component support 1, a reciprocating component 2, a slideway plate component 3 and a reel fixing component 4, the device By turning the lead screw to reduce the distance between the two reel fixing components, the reel can be clamped, and at the same time, the distance between the reel and the lead pipe can be reduced, so that the wire maintains a certain degree of tension during the winding process. Tension degree; the device is equipped with a reciprocating component to make the thread more evenly wound on the reel; the device is equipped with a lead tube, which is not easy to cause winding disorder, and the end face of the lead tube is in the form of an excessive arc to prevent the thread from winding In the process, it is broken due to friction, which reduces the phenomen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com