Systems and methods for controlling airflow through power steering system

A technology of controller and engine speed, applied in the direction of power steering mechanism, steering mechanism, engine control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

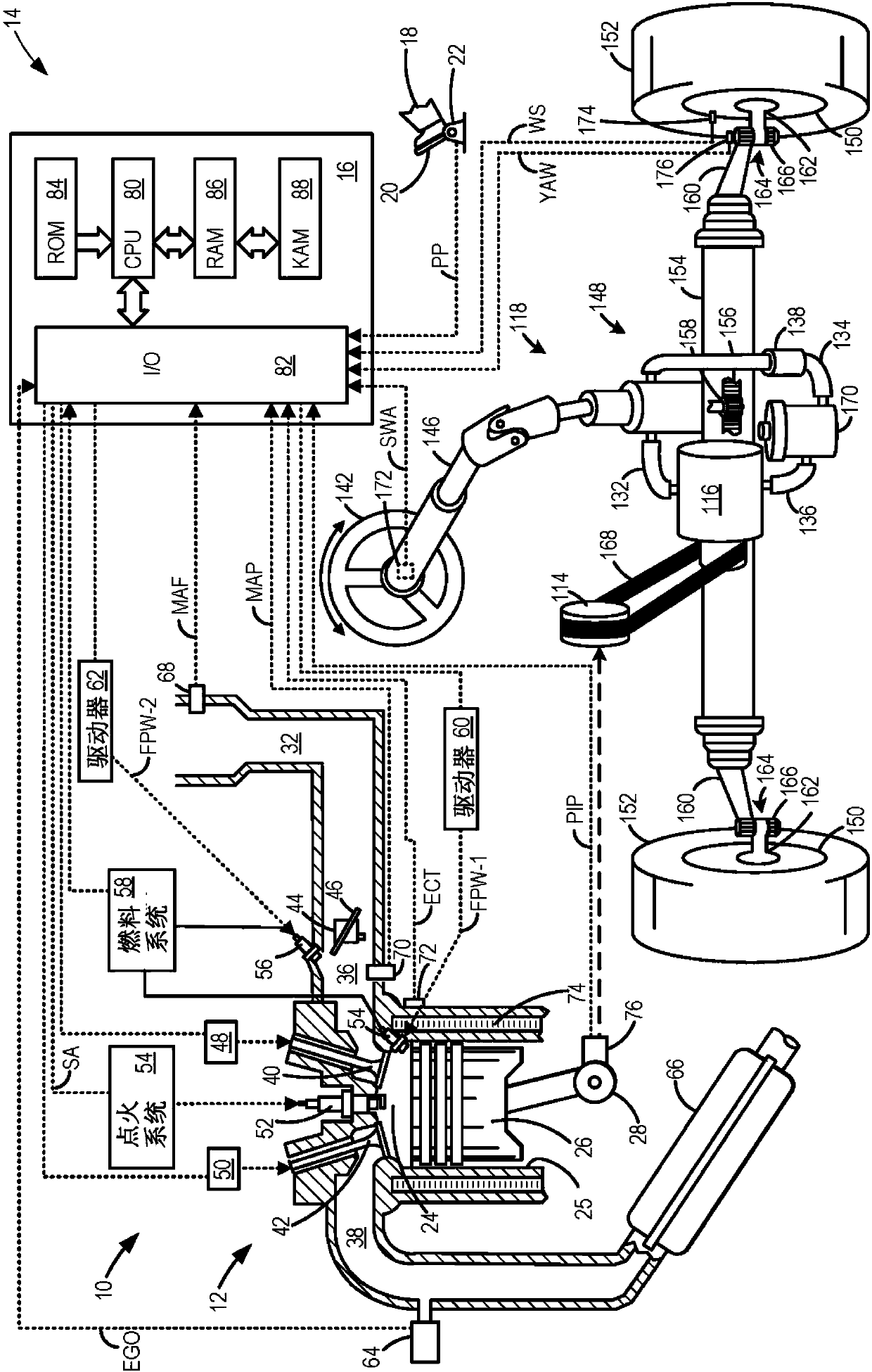

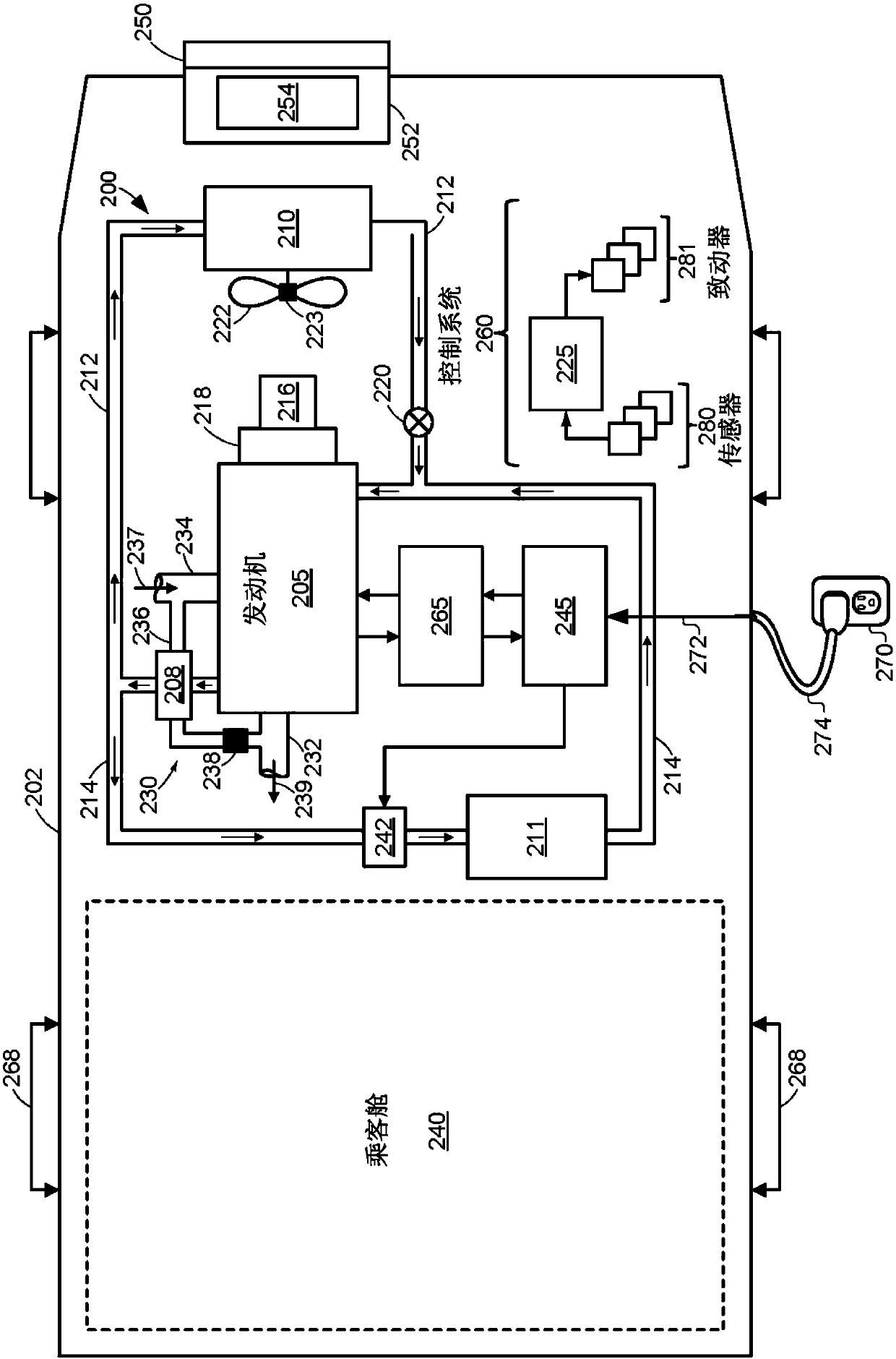

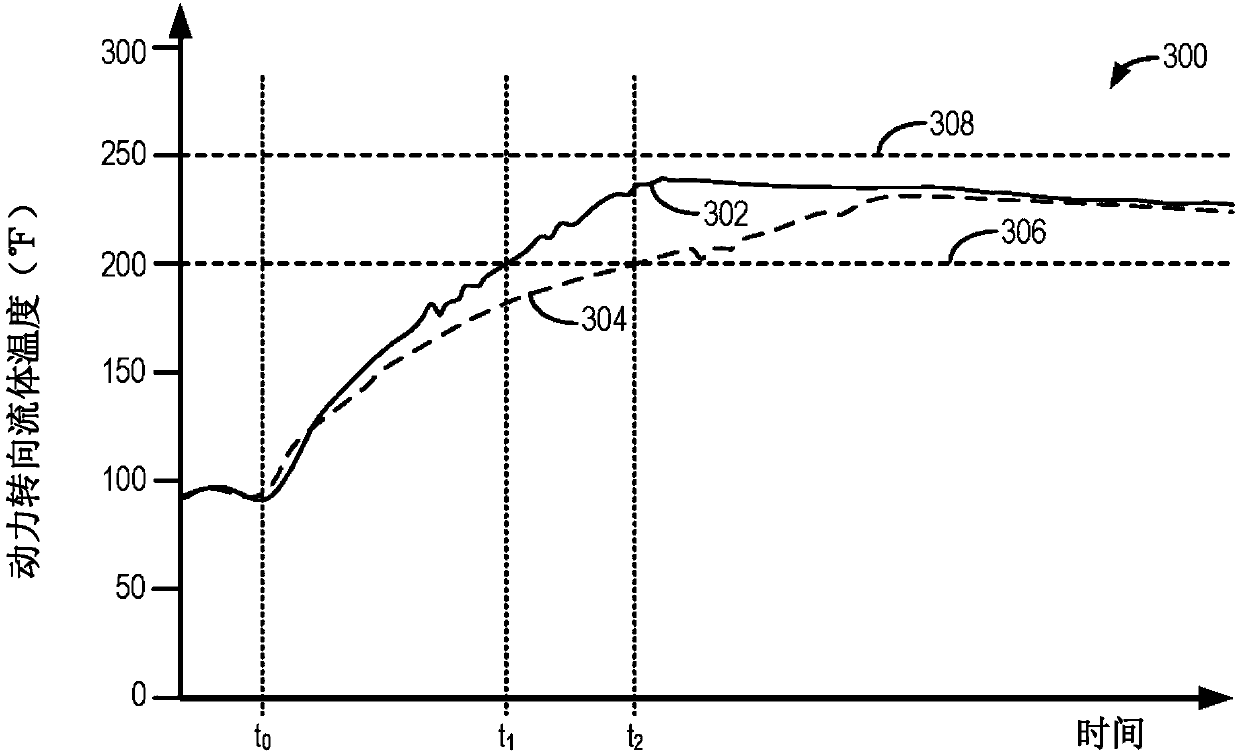

[0016] The following description relates to systems and methods for a vehicle power steering system. More specifically, the description relates to actively mitigating power steering fluid overheating by activating an engine cooling fan based on engine speed and steering wheel angle. Such as figure 1 As shown in , a vehicle power steering system may include a hydraulic steering fluid circuit with a high pressure pump. The high pressure pump may be belt driven and coupled to the vehicle engine as part of the auxiliary drive bracket. Therefore, the pump can rotate at a speed proportional to the rotational speed of the engine, thereby generating heat. Additionally, as the steering wheel angle increases, the pressure in the power steering system can also increase, further increasing the temperature of the steering fluid. The hydraulic power steering fluid circuit may include a cooler configured to reduce the temperature of the steering fluid. However, in response to an increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com