Crankshaft pulley assembly

A crankshaft pulley and pulley technology, applied in the field of auto parts, can solve the problems of unstable speed of belt drive accessories, fluctuation of engine crankshaft speed, unstable speed, etc., to achieve simple structure, reduce output speed fluctuation, and belt output stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

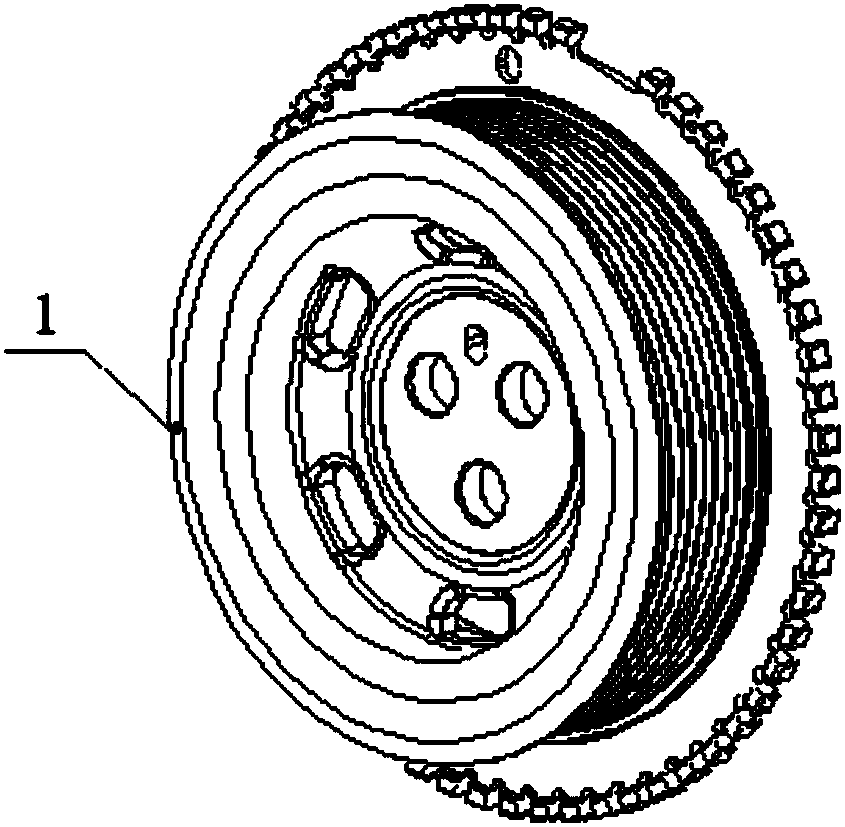

[0014] figure 1 Shown is the structural representation of the present invention.

[0015] The invention can reduce the torsion angle of the crankshaft of the engine, can read the rotational speed of the engine, allows a larger angular displacement between the pulley and the hub, and can make the belt output a more stable crankshaft pulley.

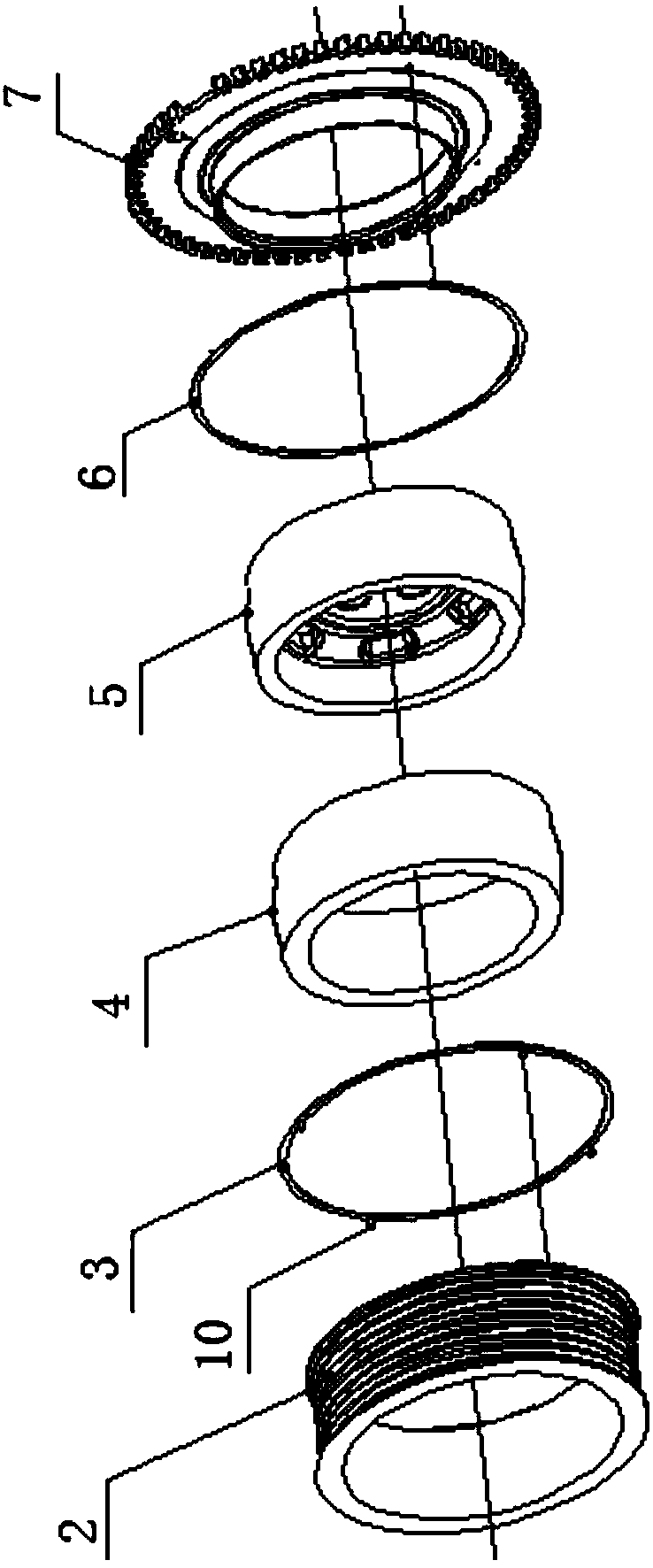

[0016] figure 2 Shown is an exploded schematic diagram of the present invention.

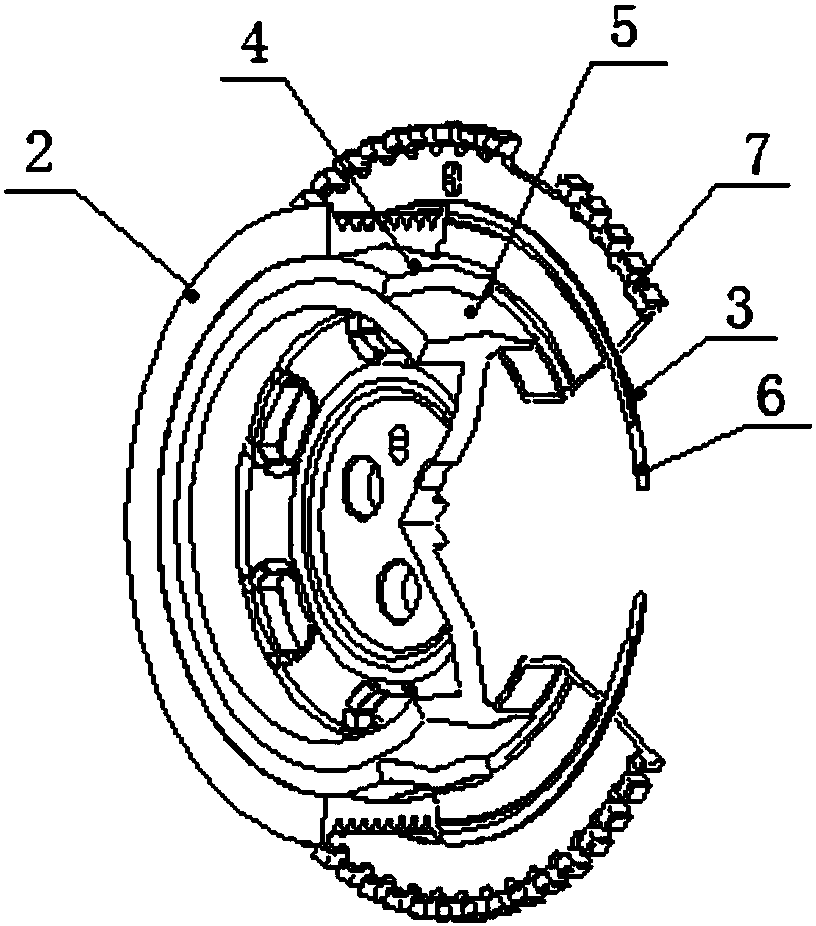

[0017] image 3 Shown is a schematic cutaway view of the belt pulley of the present invention.

[0018] The present invention comprises belt pulley 2, friction plate one 3, damping rubber 4, wheel hub 5, friction plate two 6 and signal disc 7.

[0019] Described signal disc 7 is provided with missing tooth 8 (as Figure 4 shown).

[0020] A signal disc 7 is pressed on the hub of the pulley 1, and the signal disc 7 with mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com