Surface shape measurement device and method based on structured light illumination

A technology of structured light illumination and measurement device, which is applied to measurement devices, optical devices, instruments, etc., can solve problems such as restricting the application of zoom surface shape measurement methods, achieve simple installation and adjustment, improve detection efficiency, and fast axial scanning speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

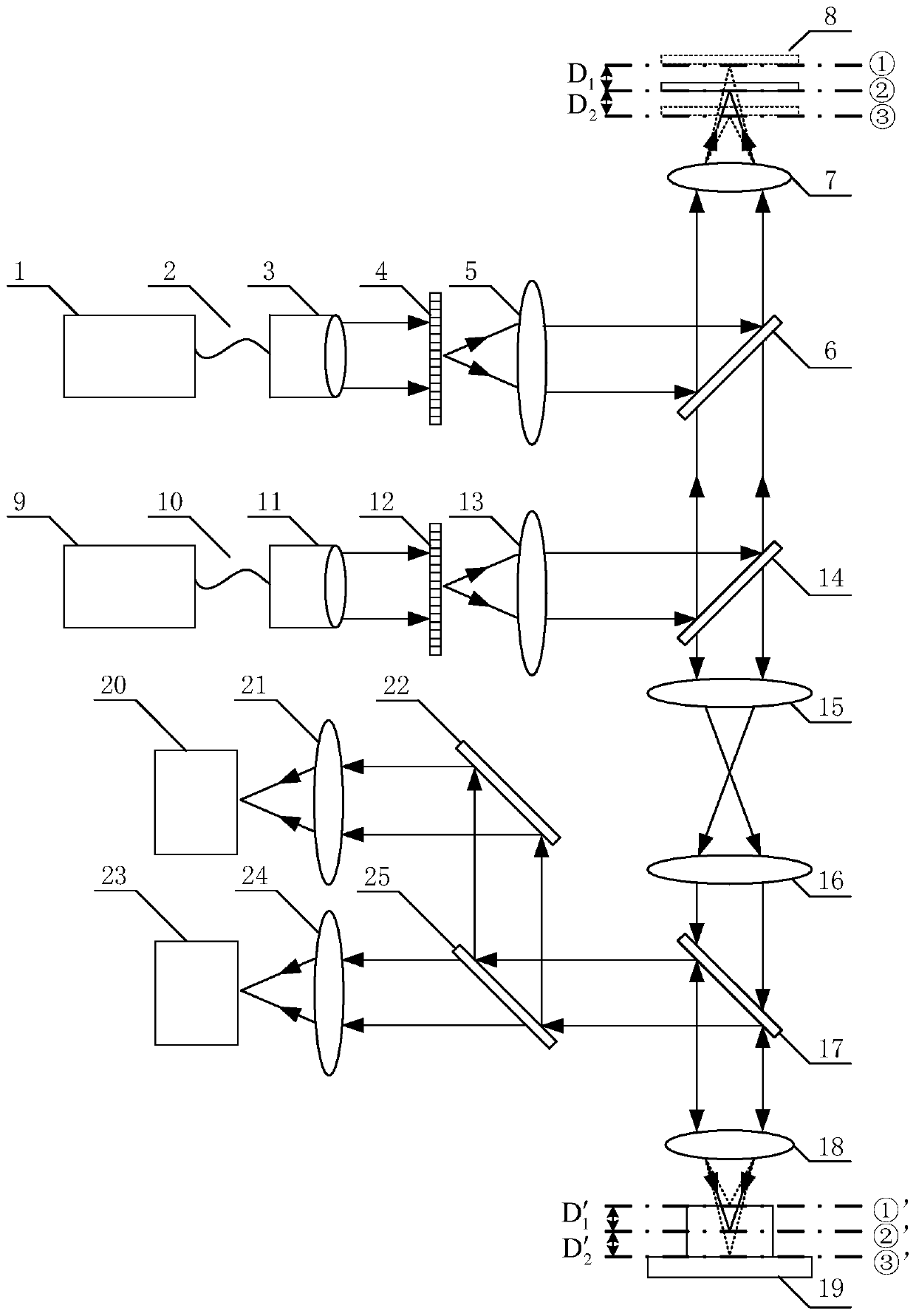

[0039] Embodiment 1: as attached figure 1 The illustrated embodiment provides a surface shape measurement device based on structured light illumination, which is used to quickly switch axial positions to realize three-dimensional tomographic scanning.

[0040] A surface shape measurement device based on structured light illumination, comprising a structured light illumination module, an axial scanning module and a detection module;

[0041]The structured light illumination module is composed of two illumination optical paths, the first illumination optical path is as follows according to the direction of light propagation: laser device-1, conduction optical fiber-2, collimator mirror-3, amplitude type sinusoidal grating-4 and tube mirror- 5. The second illumination light path is as follows according to the direction of light propagation: laser 2 9, conduction fiber 2 10, collimator 2 11, amplitude type sinusoidal grating 2 12 and tube mirror 2 13;

[0042] According to the li...

Embodiment 2

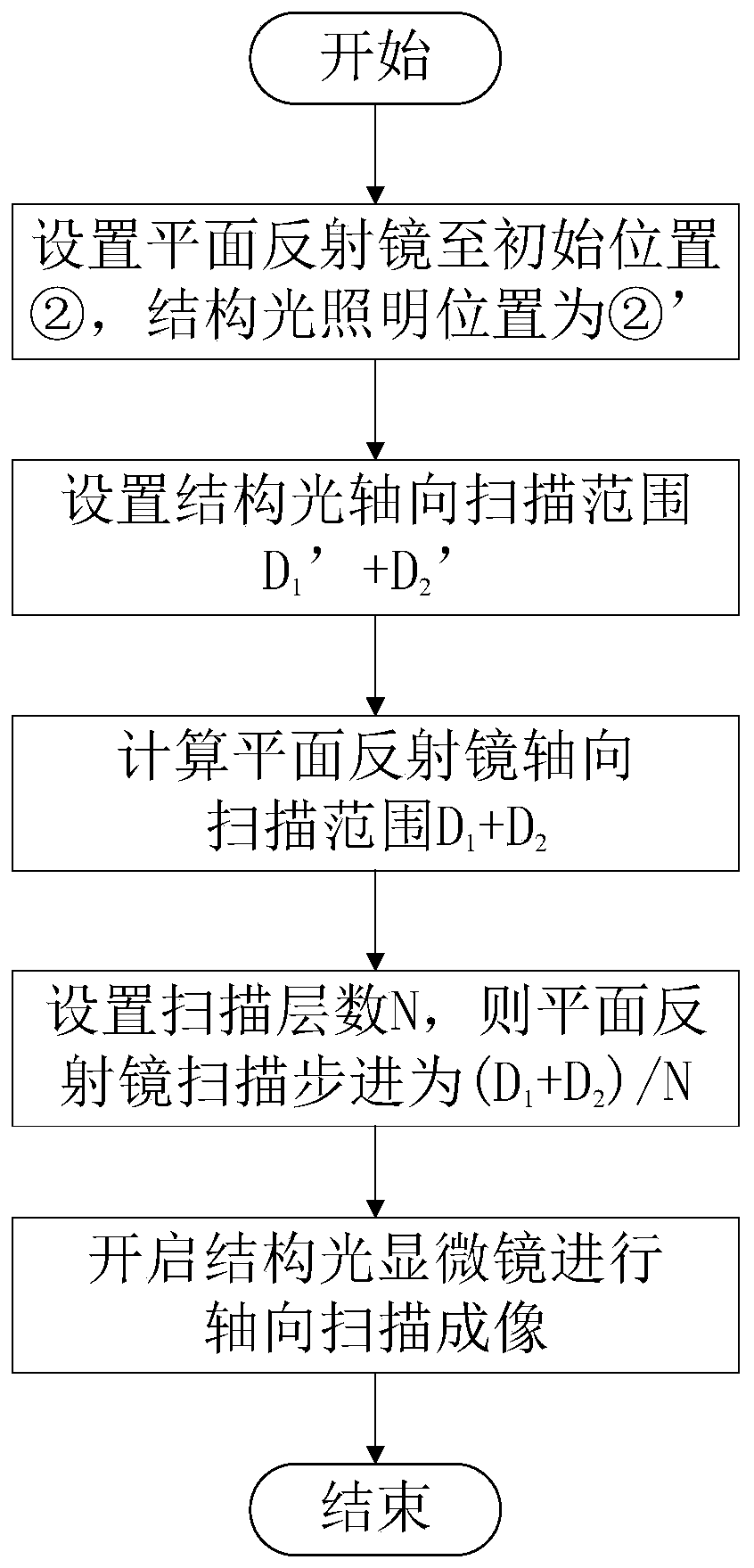

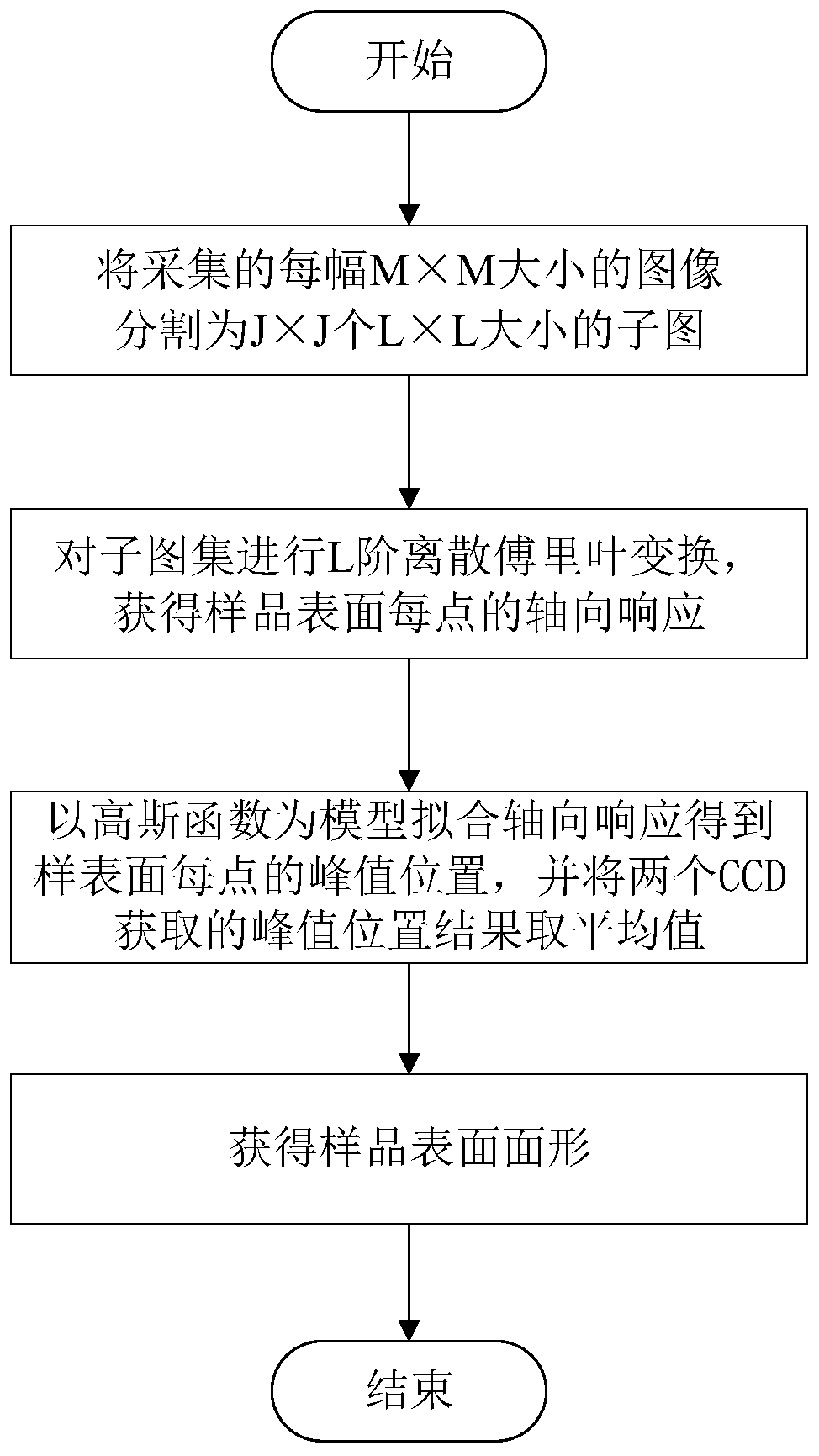

[0052] Embodiment 2: as attached figure 1 and figure 2 The illustrated embodiment provides a surface shape measurement method based on structured light illumination, which is used to quickly switch axial positions to realize three-dimensional tomographic scanning.

[0053] A method for measuring surface shape based on structured light illumination, the method is implemented based on the surface shape measurement device based on structured light illumination described in Embodiment 1, and the specific steps are:

[0054] Step a, the laser 1 emits excitation light, and forms parallel light after passing through the conductive fiber 2 and the collimating mirror 3. The parallel light is modulated by the amplitude type sinusoidal grating 1 4 and then emitted by the tube mirror 1 5. At the same time, the laser 2 9 emits The excitation light forms parallel light after passing through the conductive optical fiber 2 10 and the collimating mirror 11. The parallel light is modulated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com