The Temperature Calibration Method of Non-contact Infrared Thermometer

An infrared thermometer and non-contact technology, which is applied in the field of infrared temperature measurement, can solve the problems of difficulty in guaranteeing the measurement error, interference error, labor consumption, etc. of the non-contact infrared thermometer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

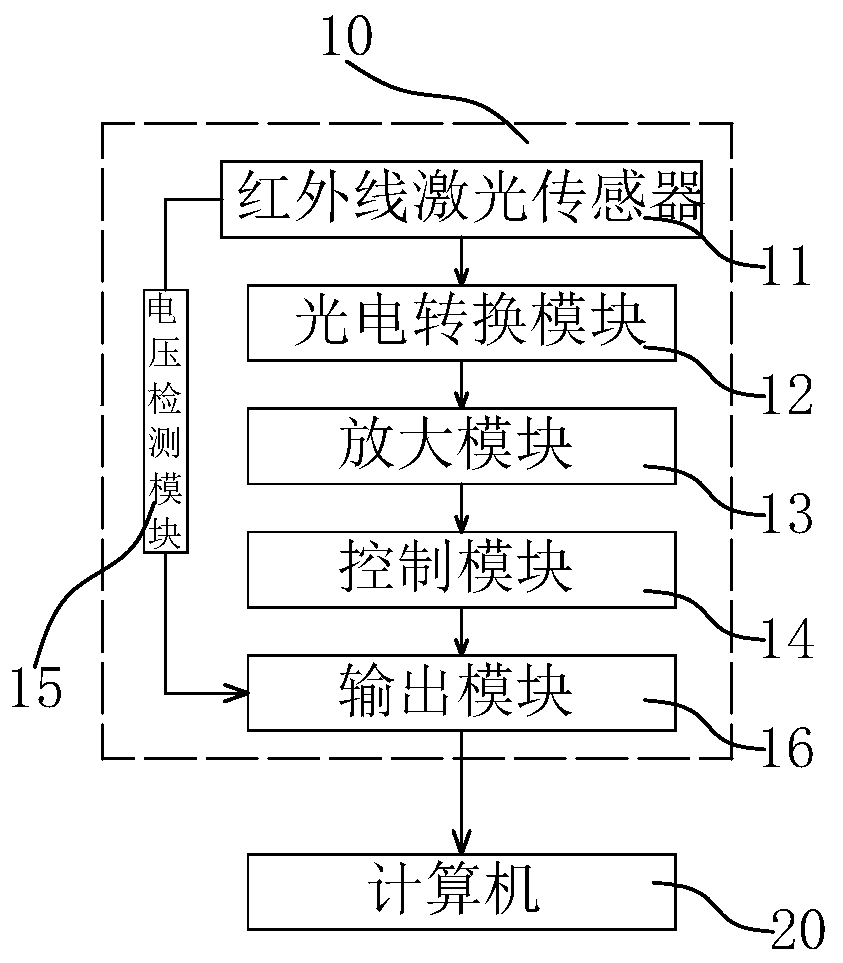

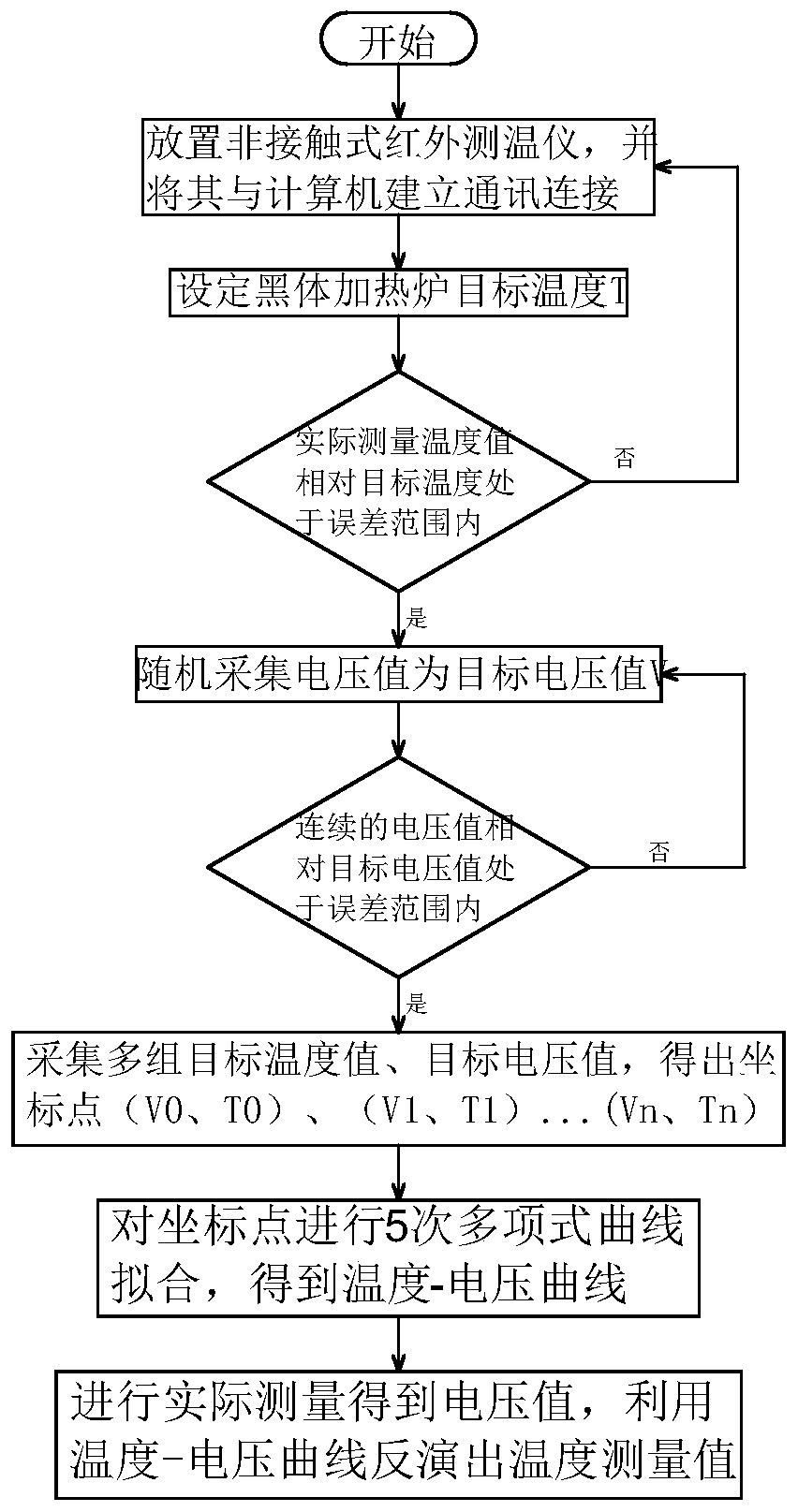

[0008] combined with figure 1 , 2 The present invention is further described:

[0009] A temperature calibration method for a non-contact infrared thermometer, comprising the steps of: A, arranging a non-contact infrared thermometer 10 in a black body heating furnace, and establishing a communication connection between the non-contact infrared thermometer 10 and a computer 20; B, the computer 20 sets the target temperature of the blackbody heating furnace as T0, and the blackbody heating furnace heats up or cools down towards the target temperature T0; C, the measured temperature value displayed by the non-contact infrared thermometer 10 in real time remains within the fluctuation range of the target temperature T0 Within, calculate whether the measured temperature value is within the error range relative to the target temperature T0, if it is to enter step D; D, the computer 20 randomly selects a time point to collect the current voltage value of the non-contact infrared the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com