Automatic temperature control PP tank and working method thereof

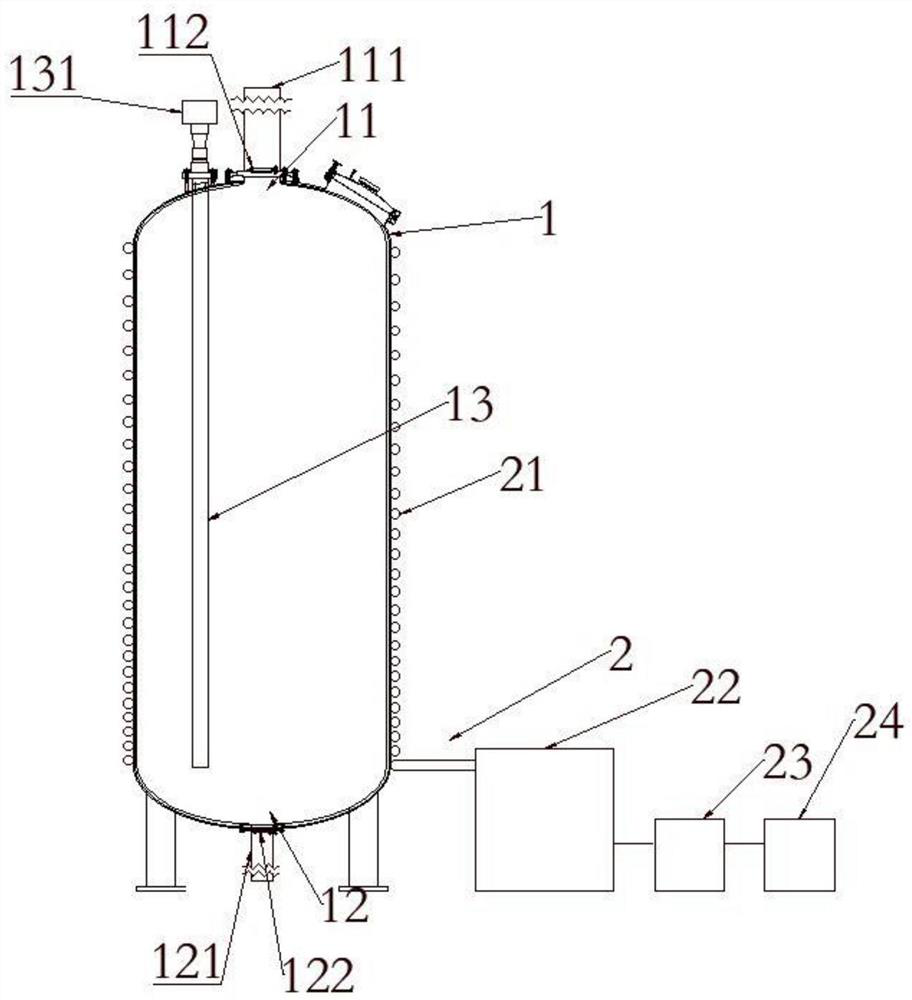

An automatic temperature control and temperature limiting technology, which is applied to tank cars, transport passenger cars, railway car body parts, etc., can solve the problems of no automatic temperature control function design of PP storage tanks, reducing the single function of the device, and difficult to accurately control the temperature, etc. To achieve the effect of long service life, simple structure and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] The working method of the PP tank of automatic temperature control of the present invention comprises the steps:

[0049] The working method comprises the steps of:

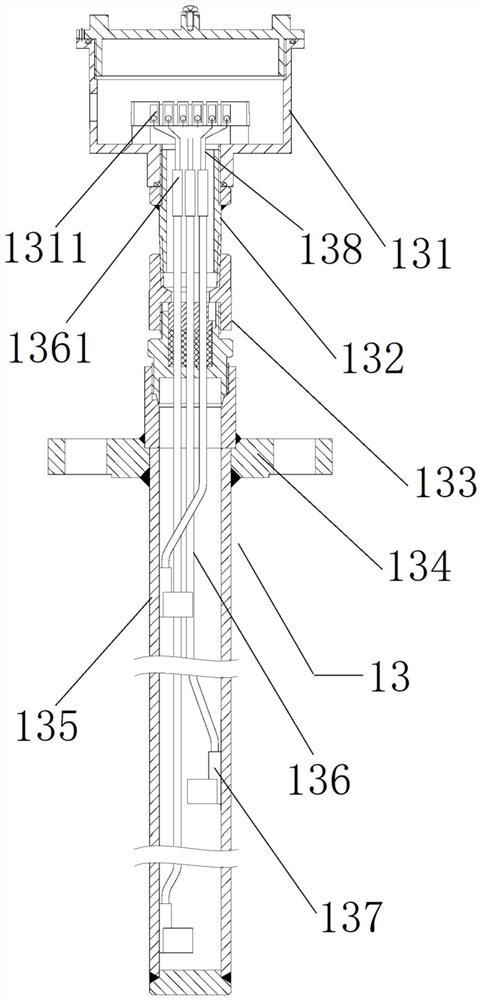

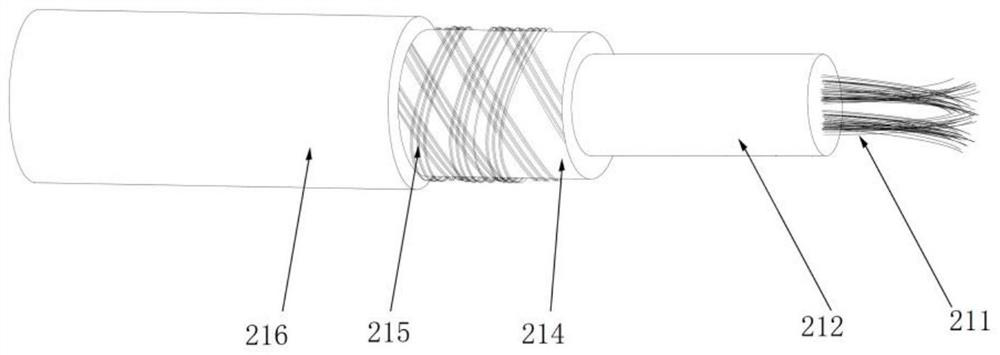

[0050] 1. Temperature control: The measuring terminals 1361 of several thermocouples 136 detect the temperature in the PP tank body 1 in real time, and transmit the real-time average temperature data to the temperature controller 221 through the intelligent digital display temperature transmitter 131, and the PP tank The temperature in the body 1 is compared with the set temperature value on the temperature controller 221, if it is lower than the set value, the temperature controller 221 controls the circuit contactor to start, closes the heating circuit, and the electric heating cable 21 is powered on to work; otherwise, If it is higher than the set value, the temperature controller 221 will control the circuit contactor to trip, cut off the heating circuit, and the electric heating cable 21 will stop wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com