Insulation and heat conduction sheath for measuring temperature of platinum resistor

A technology of insulating heat conduction and insulating sheath, which is applied in the direction of measuring heat, thermometers, thermometers using electric/magnetic components that are directly sensitive to heat, etc. Inconvenience and other problems, to achieve the effect of convenient installation, improved safety, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

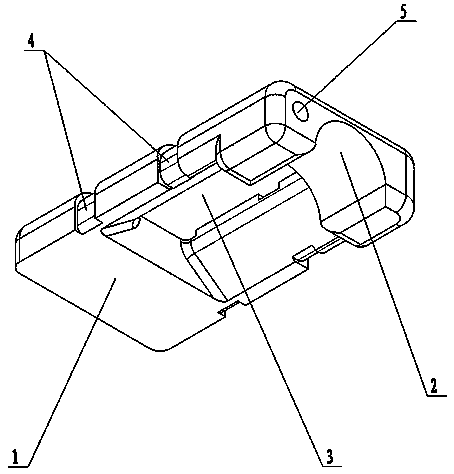

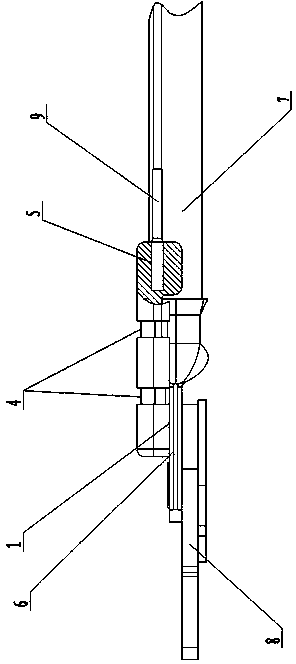

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] The base material of the insulating sheath of the platinum resistance temperature measuring insulating and heat-conducting sheath of the present invention can be selected from 95-99% alumina ceramics, which has better insulating performance and thermal conductivity. For example, the performance indicators of 99.8% alumina ceramics are shown in the table below:

[0014] performance unit Alumina Ceramics Alumina content wt% ≥ 99.8 Bulk density g / cm 3 3.90 Hardness (hra) hra ≥ 88 Bending strength mpa ≥ 400 Maximum operating temperature ℃ ≥ 1500 Air tightness test pass Thermal Shock Test pass Linear expansion coefficient ×10 -6 / ℃ 8.2 Dielectric constant ε r 20℃, 1mhz 9.2 Dielectric loss tanδ××10 -4 , 1mhz 2 volume resistivity ω·cm 20°C 10 14 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| alkali resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com