Integrated module, design method thereof and mobile terminal

A technology of integrated modules and design methods, applied in CAD circuit design, calculation, special data processing applications, etc., can solve the problems of low module welding yield and difficulty in miniaturized module production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

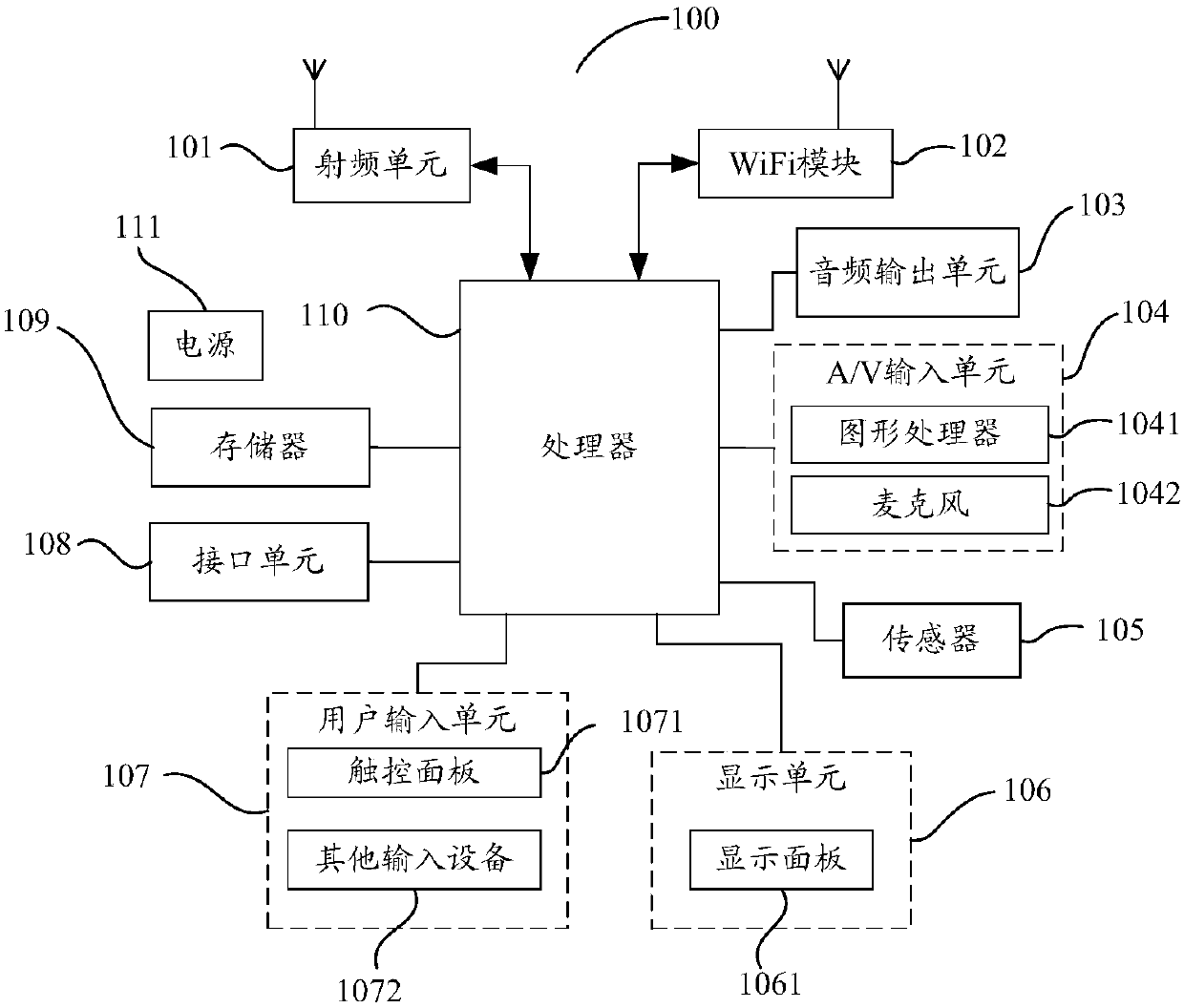

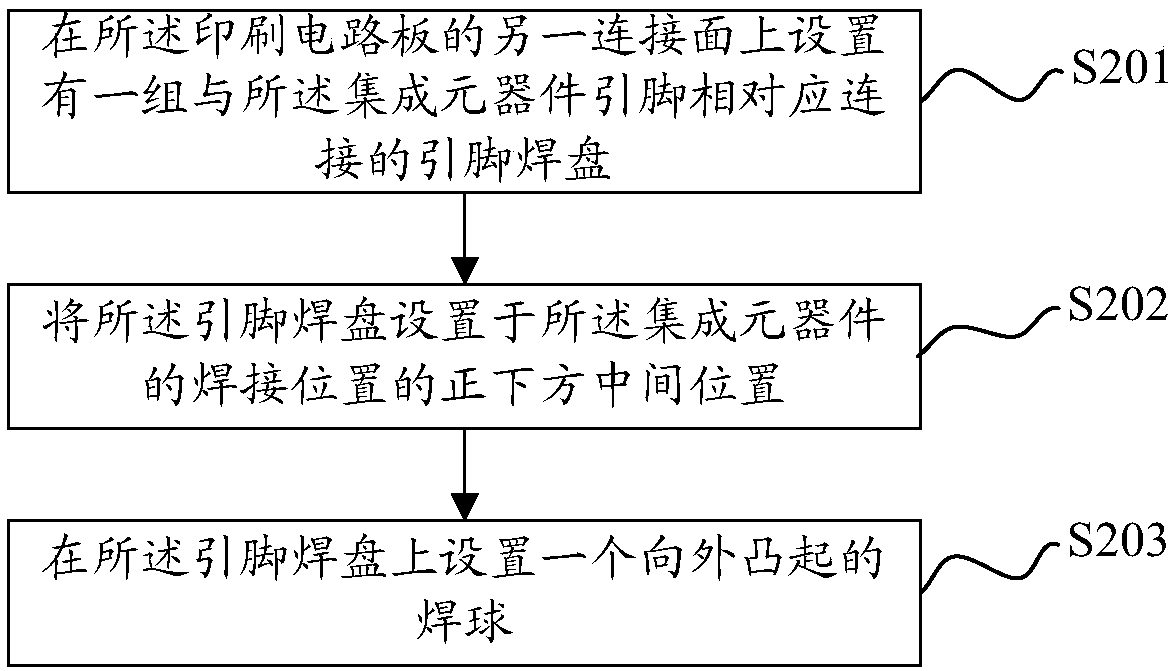

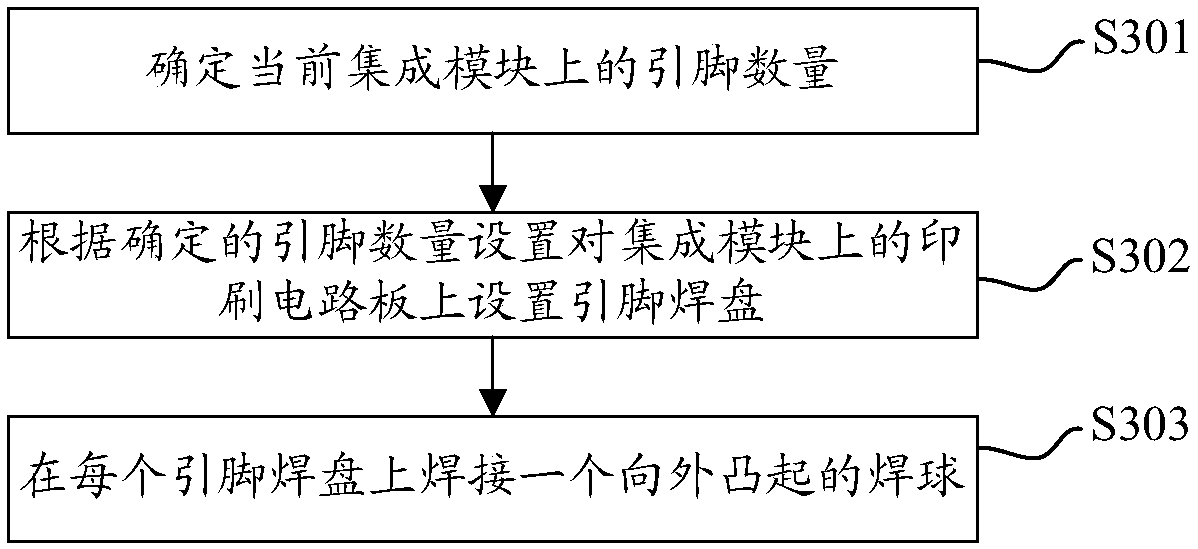

[0052] The design method of the integrated module provided by the embodiment of the present invention is applicable to various mobile terminals, including PCs, mobile phones, tablets, notebooks and other terminals. For details, please refer to figure 2 , figure 2 The basic flow chart of the design method of the integrated module provided in this embodiment, wherein the integrated module includes a printed circuit board and an integrated component, and the integrated component is soldered on a connecting surface of the printed circuit board; the design method include:

[0053] S201. A set of pin pads corresponding to the pins of the integrated component are provided on the other connecting surface of the printed circuit board.

[0054] S202. Set the pin pad at a middle position directly below the welding position of the integrated component.

[0055] S203. A solder ball protruding outward is arranged on the pin pad.

[0056] In the present embodiment, when the pin pads are arranged i...

no. 2 example

[0077] Figure 4 This is a schematic structural diagram of the integrated module provided by the second embodiment of the present invention. As shown in the figure, the integrated module 3 includes integrated components 31 and a printed circuit board 32, wherein the printed circuit board 32 includes a pin setting surface 321 and The device mounting surface 322, the integrated component 31 is soldered on the device mounting surface 322 of the printed circuit board 32.

[0078] A set of pin pads 1 are provided on the pin setting surface 321 of the printed circuit board 32, wherein the pin pads 1 are respectively connected to the pins in the integrated component 31.

[0079] The setting position of the pin pad 1 is located in the middle position directly below the welding position of the integrated component 31, and a solder ball 10 protruding outward is also provided on the pin pad.

[0080] In practical applications, in order to further reduce the footprint of the pin pad 1 on the pri...

no. 3 example

[0088] Please refer to Figure 5 , Figure 5 This is a schematic structural diagram of a mobile terminal provided by the third embodiment of the present invention. The mobile terminal includes at least one integrated module 3, which is specifically the integrated module provided in the above embodiment, and the integrated module 3 includes integrated components 31 And printed circuit board 32, where:

[0089] The integrated component 31 is soldered on one connecting surface of the printed circuit board 32, and a set of leads corresponding to the pins of the integrated component 31 are provided on the other connecting surface of the printed circuit board 32. Foot pad 1;

[0090] The setting position of the pin pad 1 is located in the middle position directly below the welding position of the integrated component 31, and a solder ball 10 protruding outward is also provided on the pin pad 1.

[0091] In this embodiment, when the pin pads 1 are set, they can be evenly distributed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com