Fully automatic waste line separation and recovery device and recovery method thereof

A separation and recycling, fully automatic technology, applied in the field of cable industry, can solve the problems of high labor cost, time-consuming and laborious, cumbersome process, etc., and achieve the effect of reducing the classification and recycling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

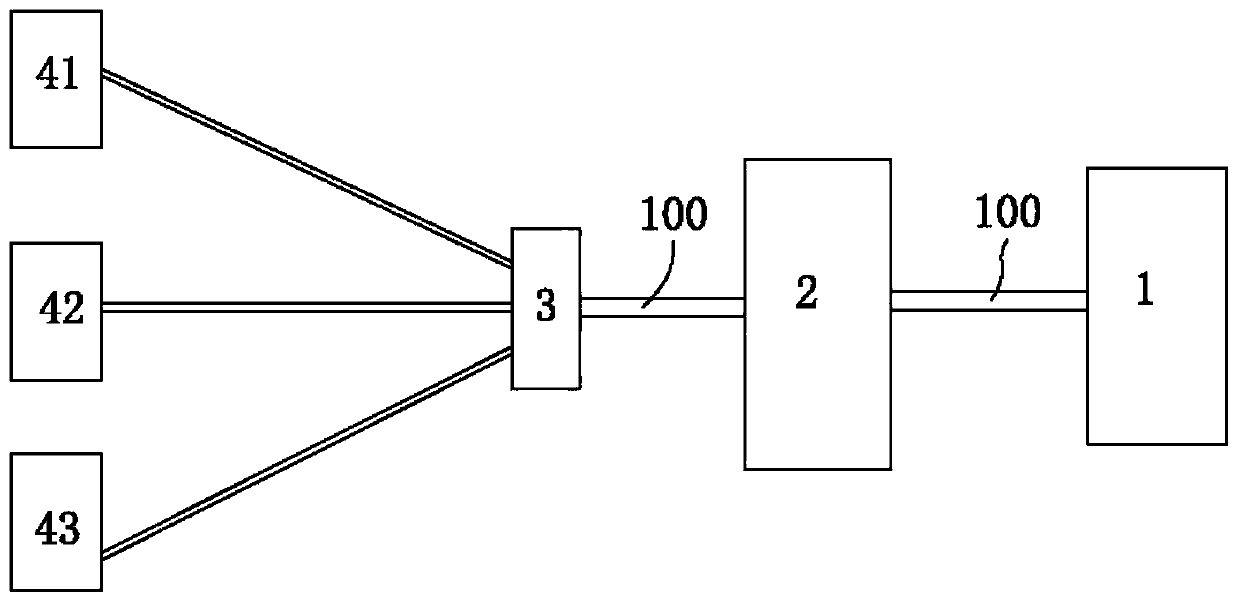

[0019] Fully automatic waste line separation and recovery device of the present invention, such as figure 1 As shown, it includes a pay-off stand 1, a peeling machine 2, a separation guide wheel 3 and 3 or more take-up stands. A wire take-up frame 41 , a second wire take-up frame 42 for storing shielding materials, and a third wire take-up frame 43 for storing conductor or core wire materials.

[0020] After the waste wire 100 is sorted by the pay-off rack 1, the sorted waste wire 100 is input to the peeling machine 2 through the pay-off rack 1, and the waste wire 100 is peeled by the peeler 2, and the waste wire 100 after peeling forms an insulating material, a shielding Material and conductor or core wire material, the waste wire 100 after stripping is input to the corresponding wire take-up frame through the separation guide wheel 3 .

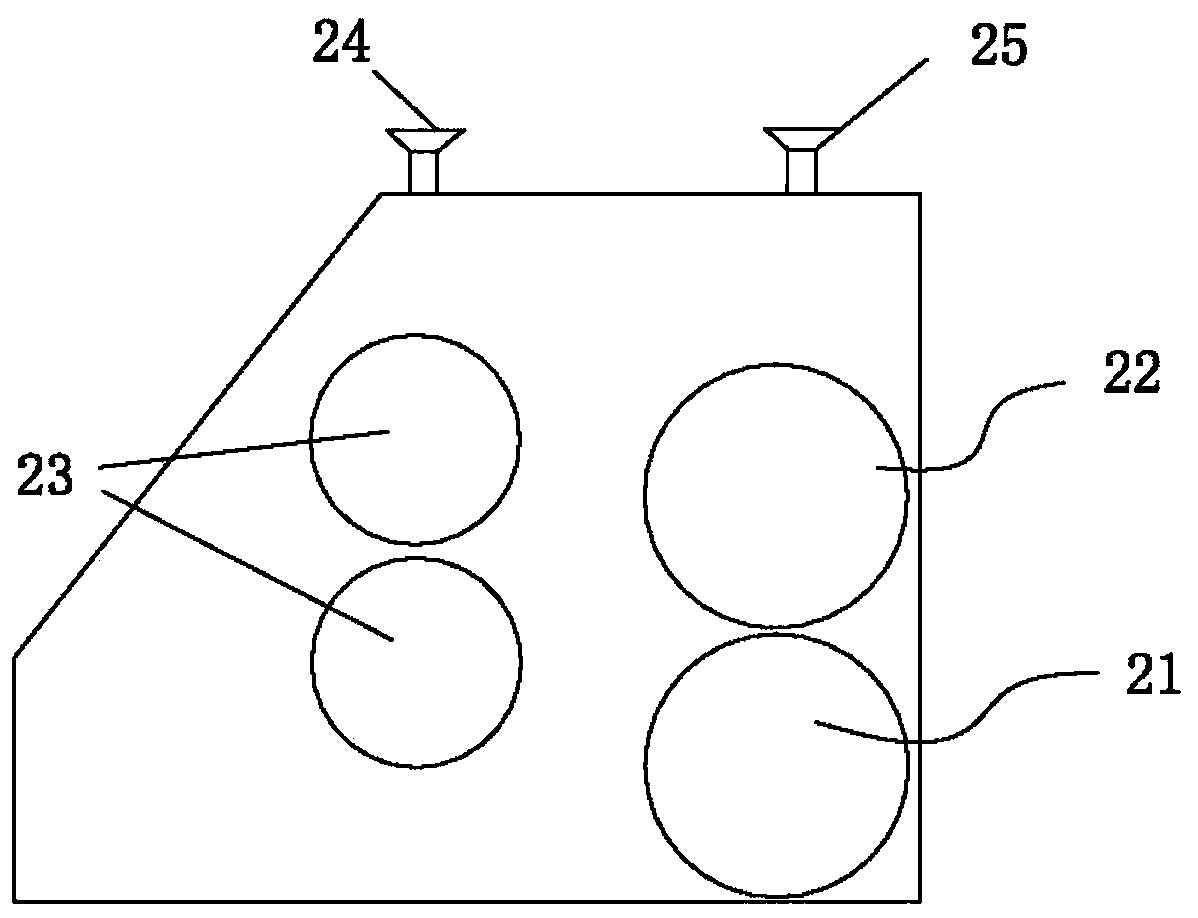

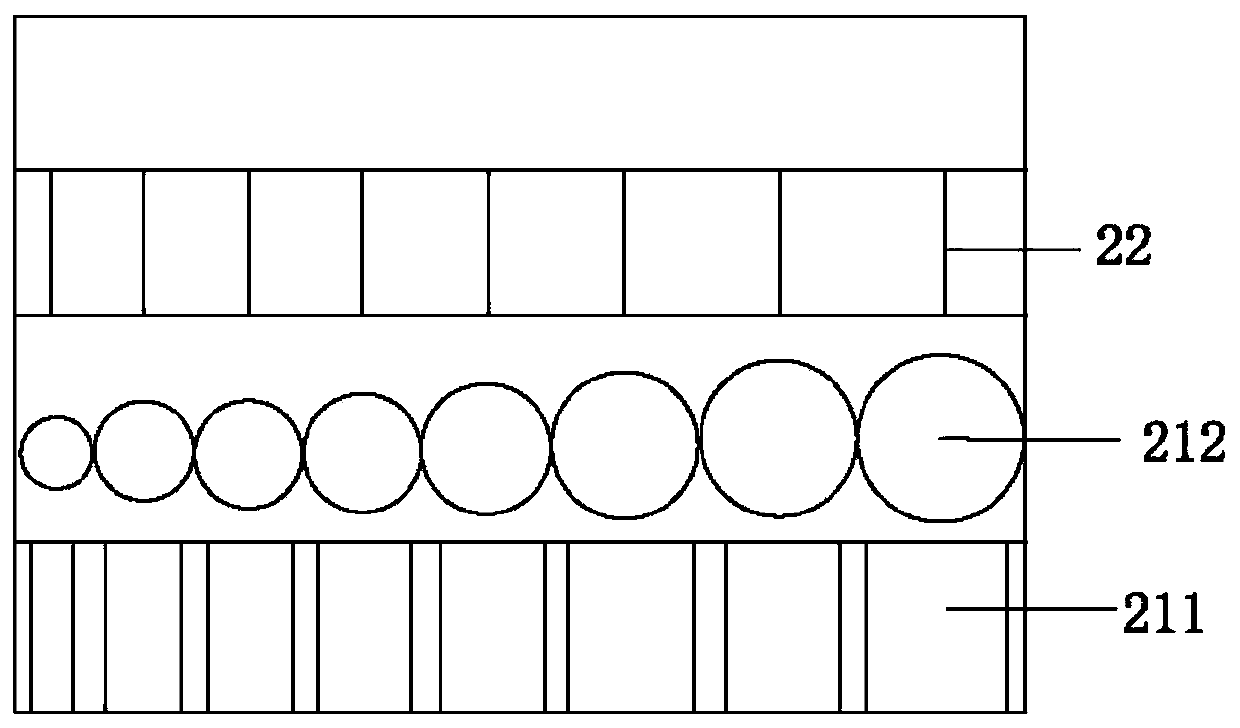

[0021] Such as figure 2 and image 3 Shown is a schematic structural view of the peeling machine, the peeling machine 2 includes a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com