Novel automatic lens printing device

An automatic printing and lens technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of inability to meet mechanical automation, simplification, low cost, high efficiency, inability to guarantee production efficiency, and complex structure. The effect of automatic operation, labor saving and high product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

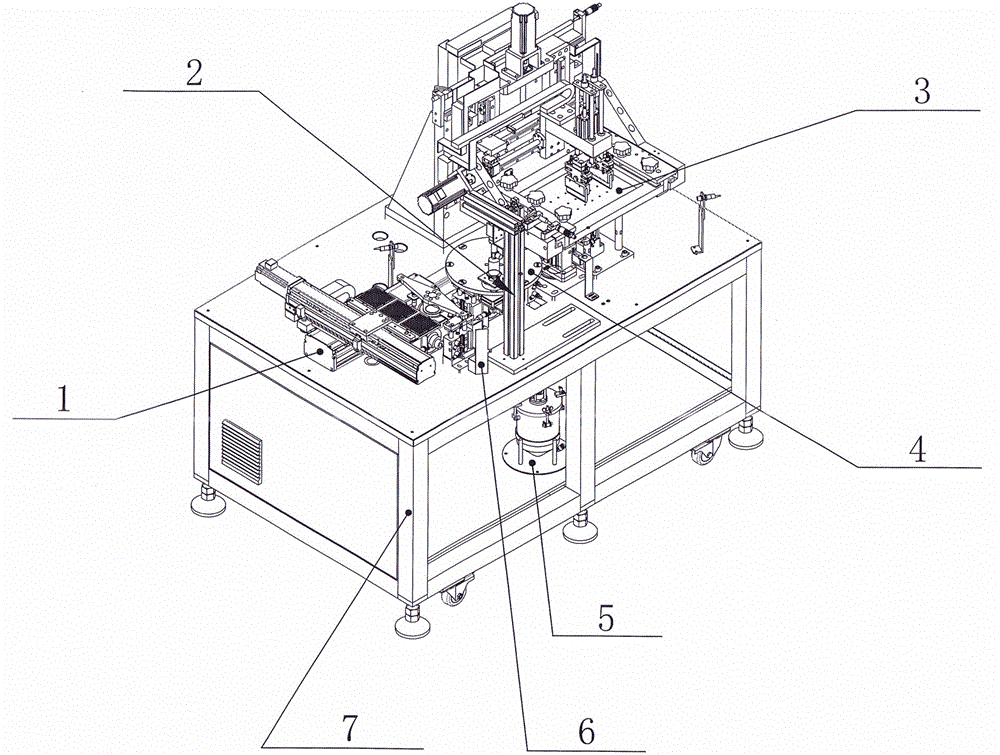

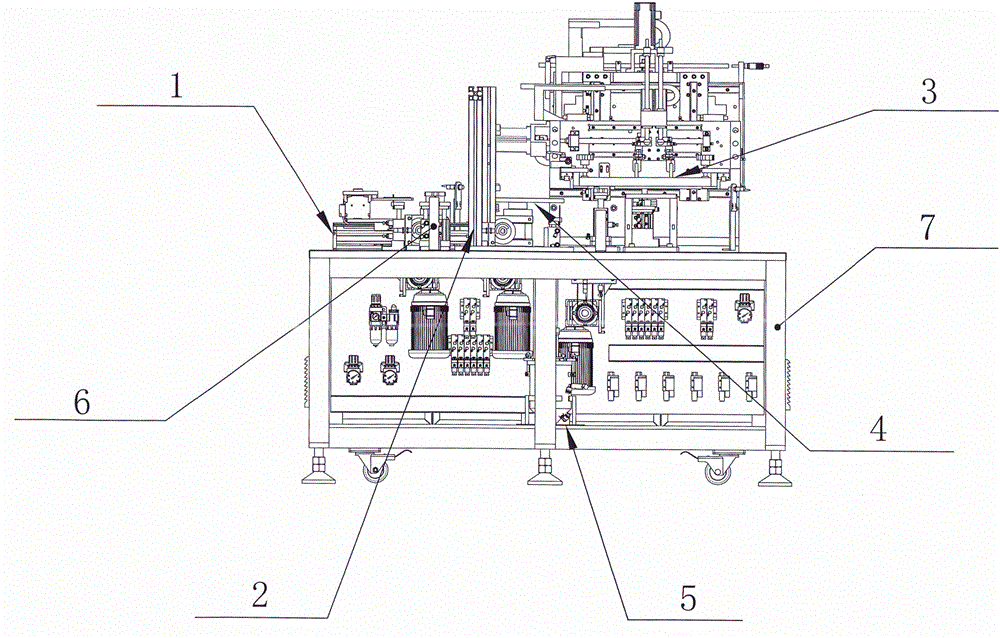

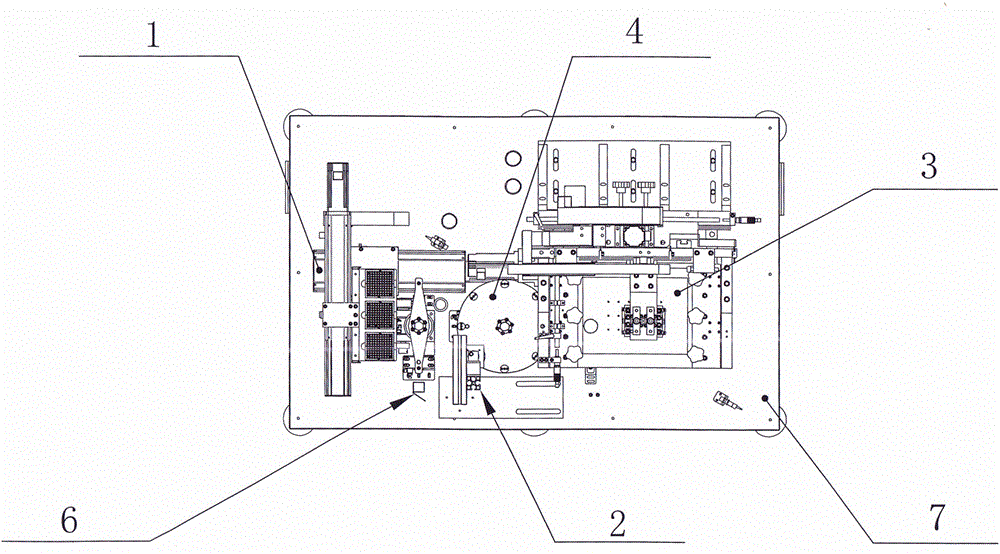

[0037] see figure 1

[0038] figure 1 It is a structural schematic diagram of the present invention. exist figure 1 Among them, a new type of automatic lens printing device, including a raw material and finished product tray mechanism 1 composed of an X-axis module and a Y-axis module, which is arranged on a frame 7 and connected to a control system in transmission. The raw material and finished product tray mechanism 1 The printing mechanism 3 is connected in transmission with the printing mechanism 3, and the printing mechanism 3 is connected with the visual detection mechanism 2 through the transport carousel mechanism 4. The printing mechanism 3 is arranged in front of the visual detection mechanism 2, and the printing mechanism 3 is also connected with the automatic ink filling mechanism 5. The visual inspection mechanism 2 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com