Control model of transformer iron core technological coefficient

A control model and technology for transformers, which are used in inductor/transformer/magnet manufacturing, instruments, electrical digital data processing, etc., can solve problems such as control models that do not involve the production process coefficients of transformer cores, and achieve the goal of improving product performance and reducing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

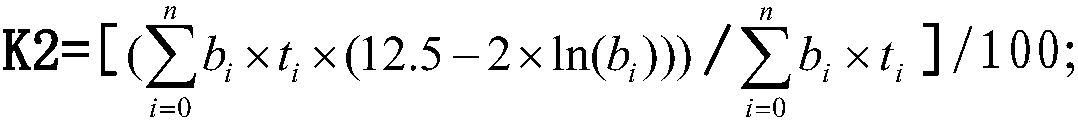

Method used

Image

Examples

Embodiment 1

[0083] The following table is the core processing data and no-load loss test results of the 80kVA distribution transformer core of a domestic iron core processing factory in December 2014. According to these data, the actual coefficient of the product can be calculated. At the same time, according to the analytical model of the present invention, The model coefficients of each process can be calculated, and then the entire iron core process coefficient model can be accurately calculated.

[0084]

[0085] It can be seen from the above table that according to the process model established in each process, the overall performance parameter (K) of the entire core calculated is very close to the process coefficient of the core obtained from the test results, the model calculation results are accurate, and the core loss performance is significantly improved.

[0086] Because the products of Comparative Example 1 and Comparative Example 2 have quality problems in shear processing,...

Embodiment 2

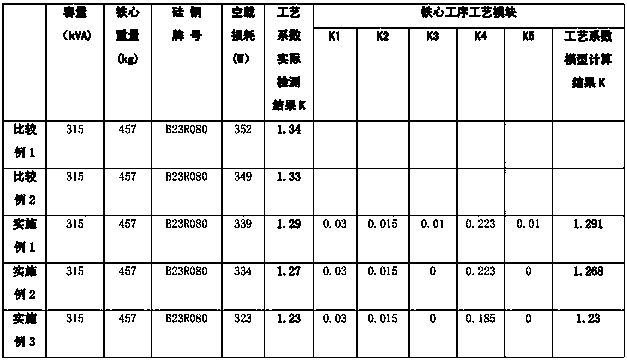

[0088] The following table is the core processing data and no-load loss test results of a 315KVA distribution transformer core in a domestic core processing factory in January 2015. According to these data, the actual coefficient of the product can be calculated. At the same time, according to the analytical model of the present invention, The model coefficients of each process can be calculated, and then the entire iron core process coefficient model can be accurately calculated.

[0089]

[0090] It can be seen from the above table that according to the process model established in each process, the overall performance parameter (K) of the entire core calculated is very close to the process coefficient of the core obtained from the test results, the model calculation results are accurate, and the core loss performance is significantly improved.

[0091] Due to problems in product structure optimization and shear processing of the products of Comparative Example 1 and Compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com