Longitudinally adjustable connecting rod

A length-adjustable and adjustable technology, applied in the directions of connecting rods, shafts, multi-way valves, etc., can solve the problem of not being able to obtain connecting rods, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0126] Elements with the same function are provided with the same reference signs in the embodiment variants shown in the figures.

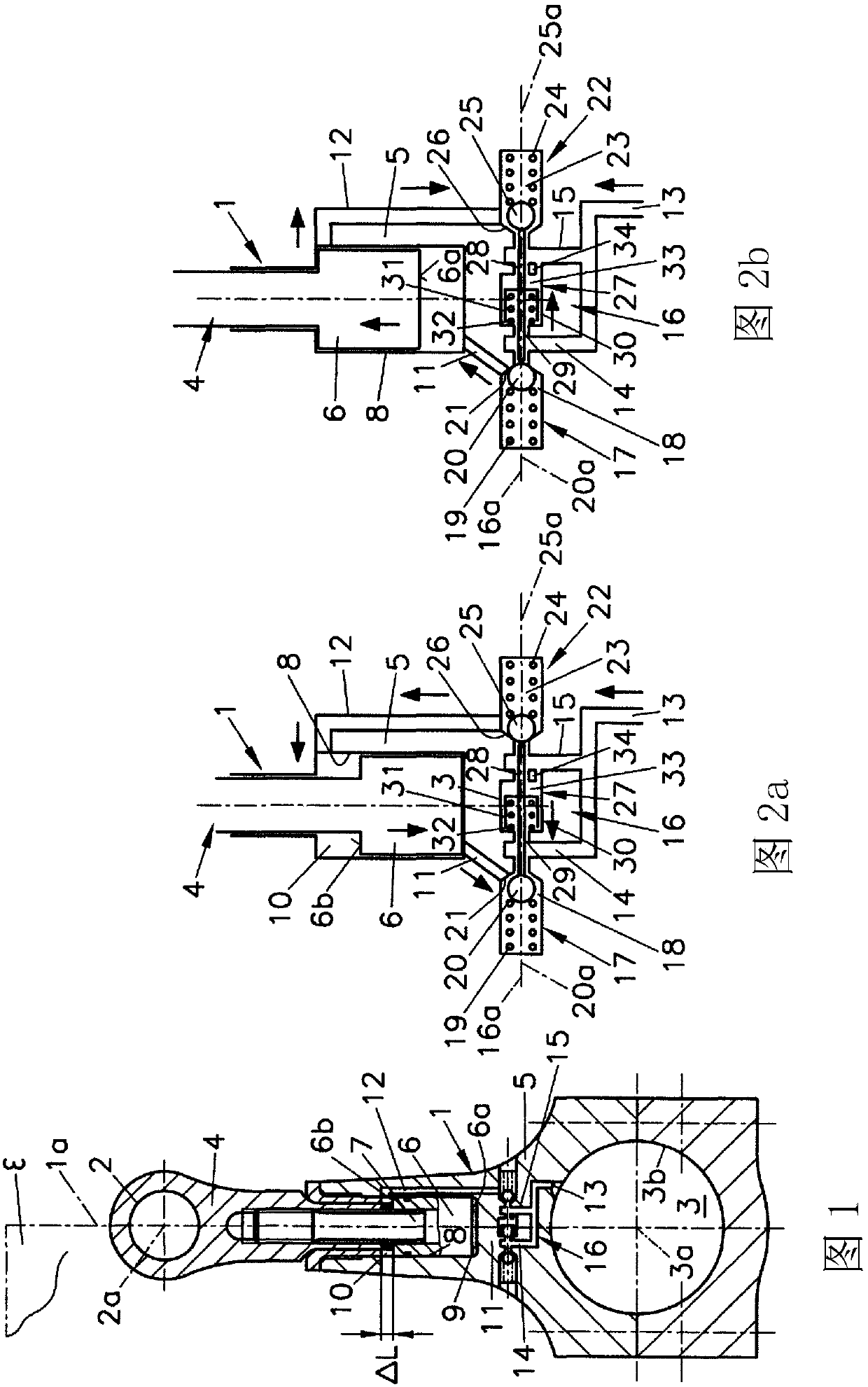

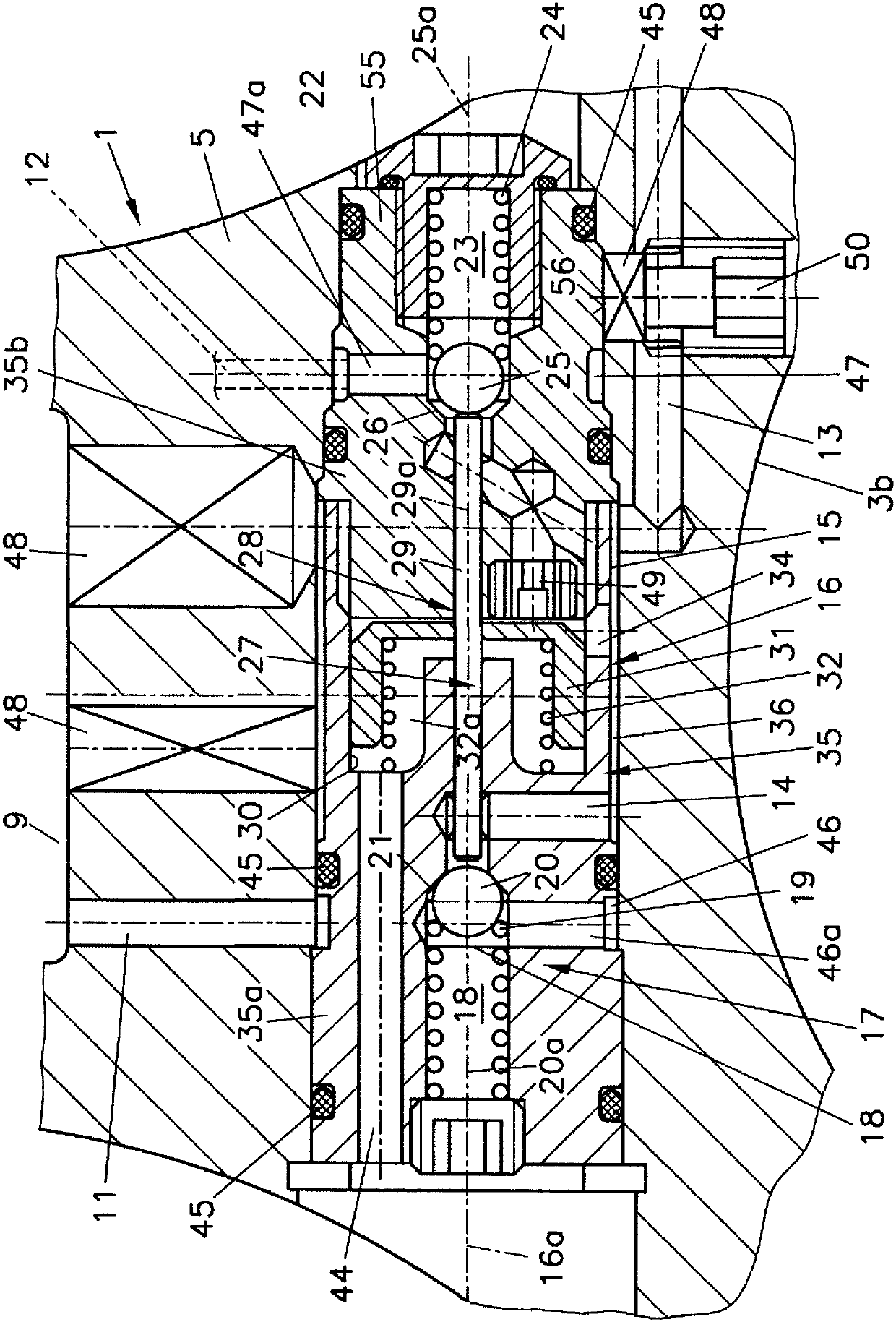

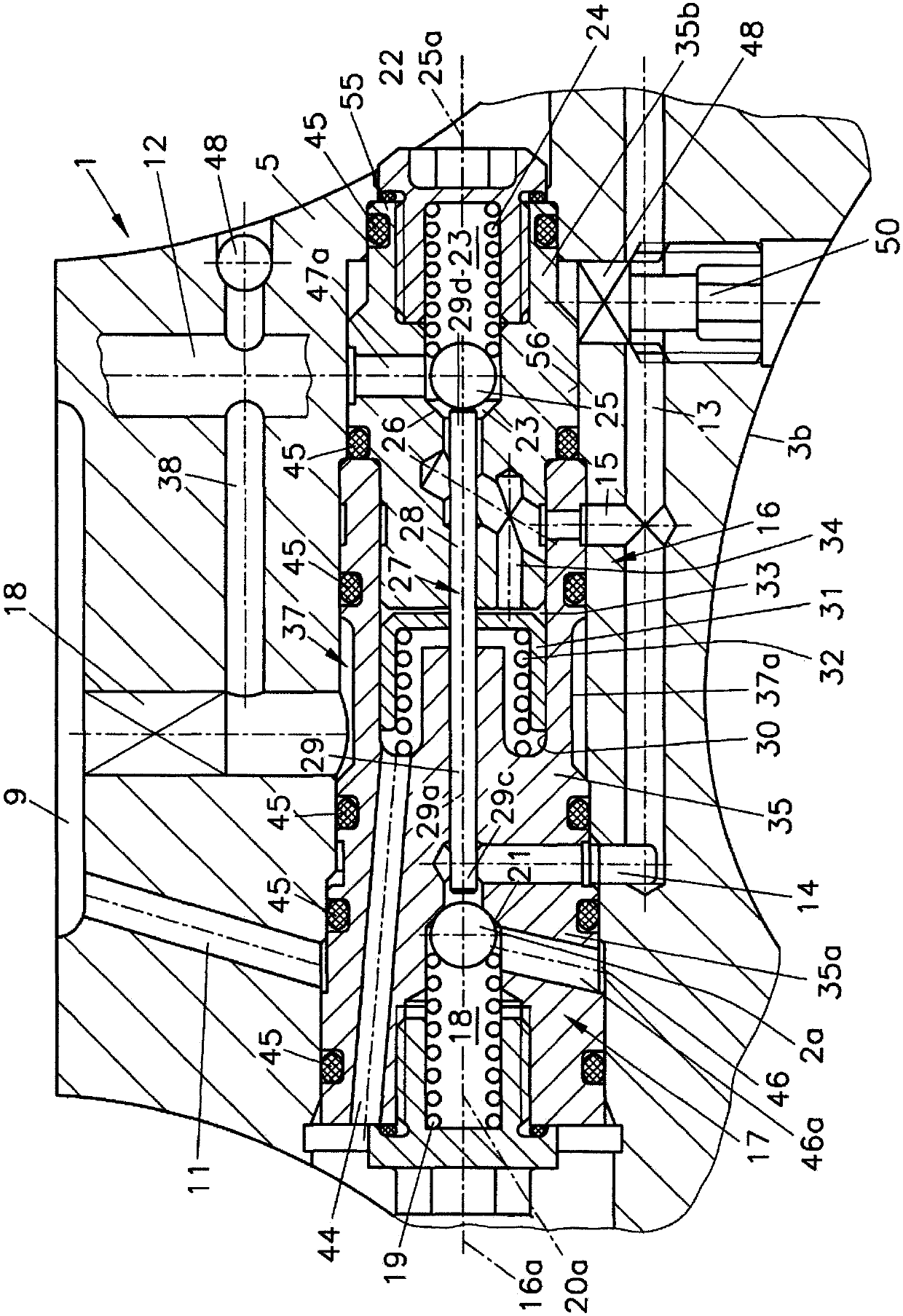

[0127] figure 1 A two-piece connecting rod 1 for a piston engine such as an internal combustion engine is shown, with a small connecting rod 2 for a piston pin bearing not shown further, and a large crankpin bearing for an internal combustion engine not shown further The connecting rod 3. The axis of rotational symmetry of the small or large connecting rods 2, 3 is denoted by 2a or 3a. The longitudinal axis of the connecting rod 1 is denoted by 1a, and the longitudinal center plane of the connecting rod 1 that is normal on the rotational symmetry axes 2a and 3a of the small and large connecting rods 2, 3 and contains the longitudinal axis 1a of the connecting rod 1 ( The swing plane) is represented by ε.

[0128] The connecting rod 1 has an upper first rod 4 with a small connecting rod 2 and a lower second rod 5 with a large connecting rod 3. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com