Liquid delivery device

A technology of liquid feeding device and side pump, which is applied in pump device, measuring device, liquid variable capacity machine, etc., can solve problems such as flow change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

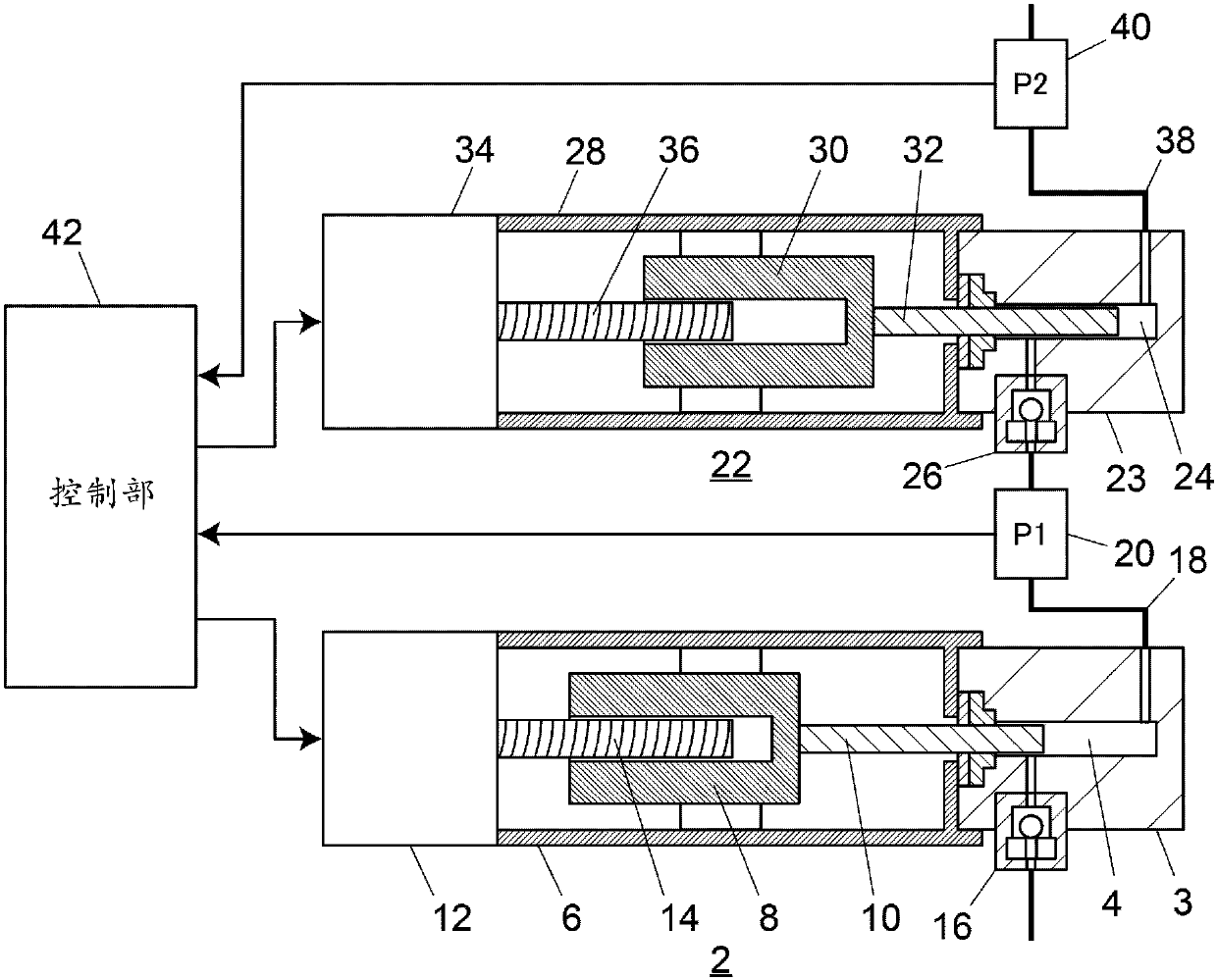

Embodiment Construction

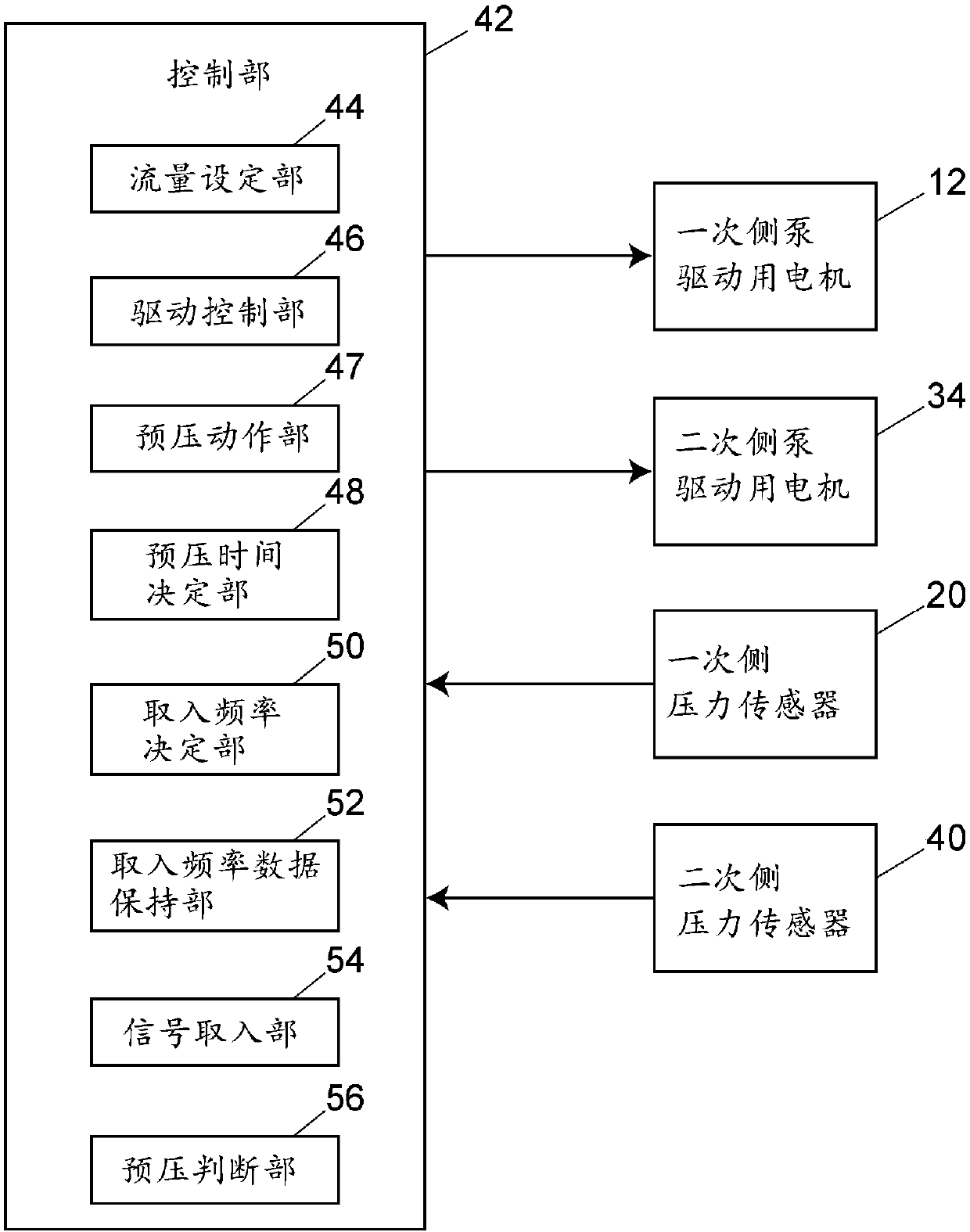

[0027] A preferred embodiment of the liquid delivery device of the present invention is further comprising: an acquisition frequency data holding unit for distributing the acquisition frequency and the acquisition frequency of signals acquired from the primary side pressure sensor and the secondary side pressure sensor to the preloading operation during the preloading operation. The relationship between the length of the preload time of the operation is held as the fetch frequency data; the fetch frequency determination unit determines the preload time based on the fetch frequency held by the fetch frequency data holding unit when the preload time is determined by the preload time determiner. The acquisition frequency is determined based on the data, and the preload operation unit is configured to acquire signals from the primary side pressure sensor and the secondary side pressure sensor at the acquisition frequency determined by the acquisition frequency determination unit.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap