Fluid mixing device

A fluid mixing and fluid mixture technology, which is applied in the directions of fluid mixers, mixers, transportation and packaging, etc., can solve the problem of difficulty in controlling the flow direction of fluid mixtures, and achieve the effect of reduced speed and easy direction control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

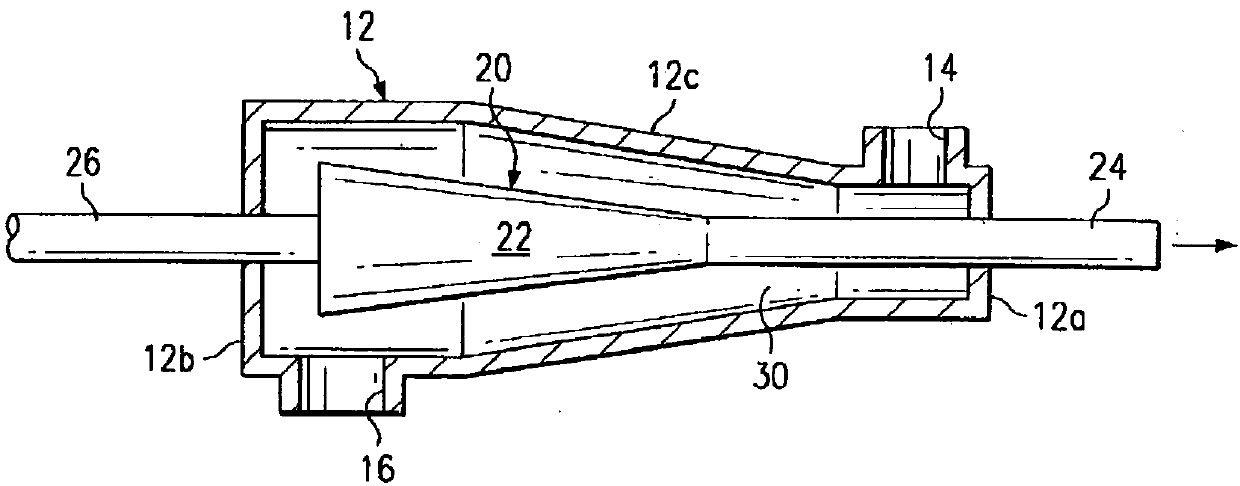

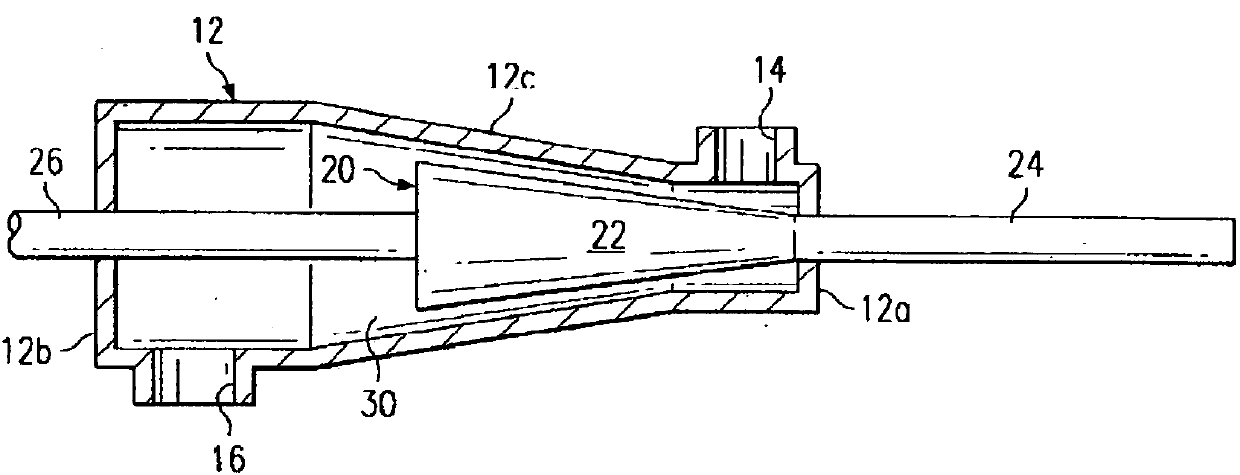

[0022] Such as figure 1 and 2 As shown, the fluid mixing device of the present invention includes a mixing shell 12 and a shear force applying device 20, the mixing shell includes a first cylindrical section 12a, a middle conical section 12c and a second cylindrical section 12b, the The first cylindrical section 12a, the middle conical section 12c and the second cylindrical section 12b are connected successively, the diameter of the first cylindrical section 12a is smaller than the diameter of the second cylindrical section 12b; the first cylindrical section 12a is provided with a fluid inlet 14 , the second cylindrical section 12b is provided with a fluid mixture outlet 16; the shear force applying device is arranged inside the mixing shell, and the shear force applying device includes a cone 22, and the cone One end of the cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com