Pipe reeling device used in electrostatic spraying equipment

A technology of electrostatic spraying and electrostatic spraying gun, which is applied in the field of pipeline coiling devices, can solve the problems of inconvenient handling of electrostatic spraying equipment, unstable hanging of electrostatic spraying guns, pedestrians being caught by pipelines, etc., and achieves the convenience of overall transportation, simple structure, avoid hanging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

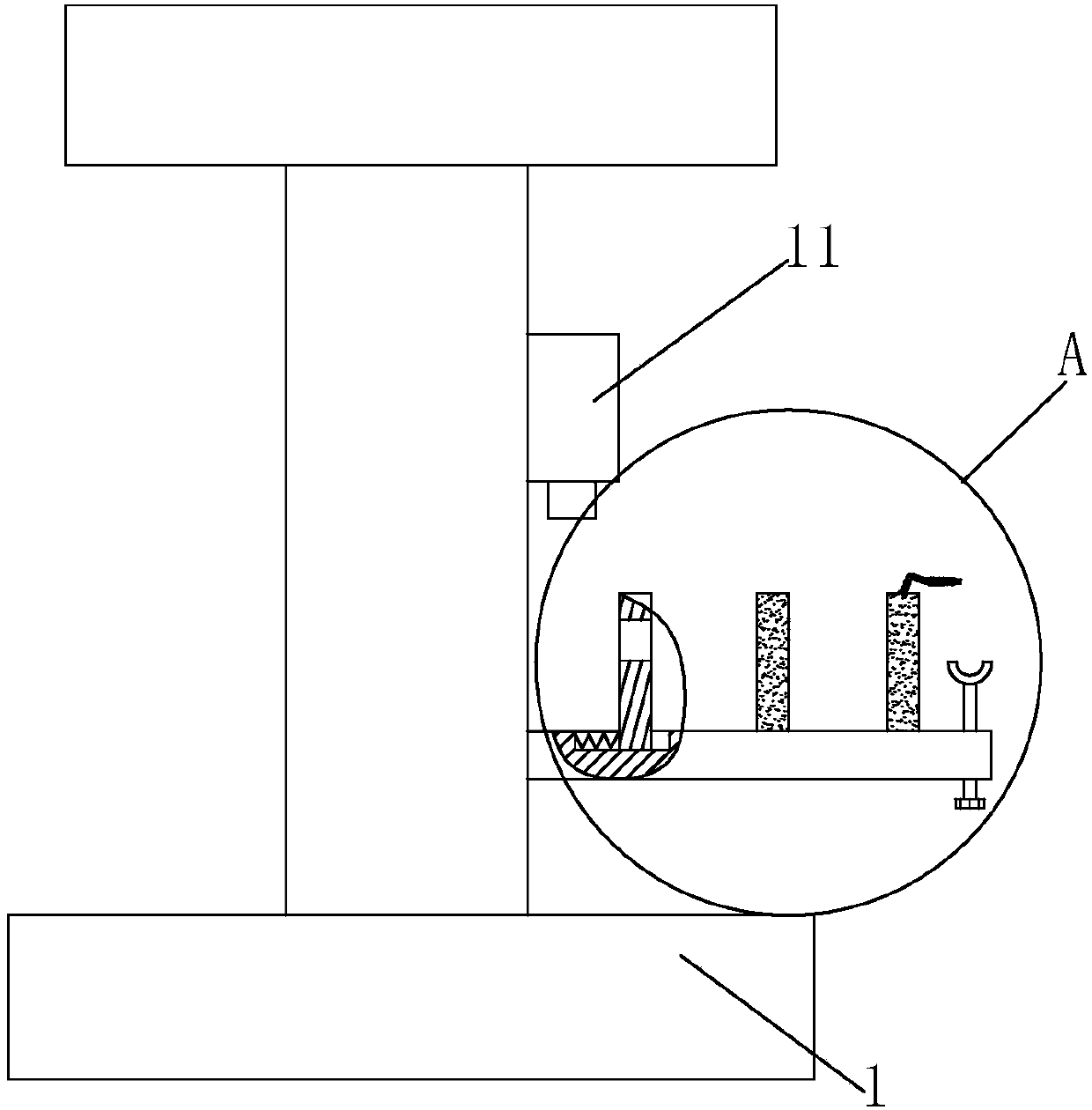

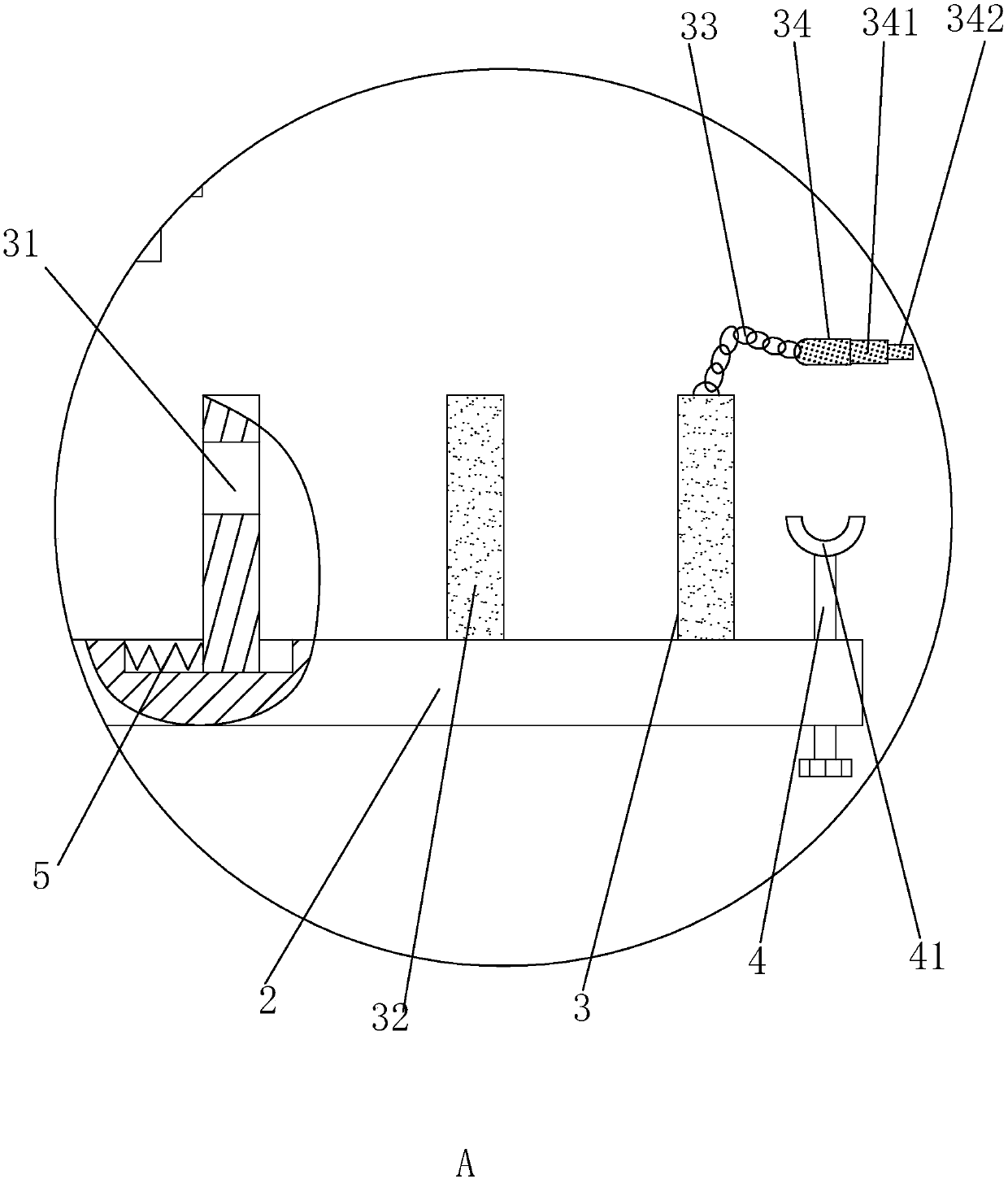

[0022] Embodiment 1: A kind of pipe coiling device used in electrostatic spraying equipment, such as figure 1 with 2 As shown, the electrostatic spraying equipment includes a machine body 1 and an electrostatic spray gun 11 suspended on the machine body 1. The pipe coiling device includes a working rod 2 fixedly arranged on the body 1 below the electrostatic spray gun 11 and perpendicular to the body 1. The working rod 2 is provided with a plurality of limiting plates 3 in the array along its length direction, and the limiting plates 3 are all slidably arranged on the working rod 2, and the positioning of the limiting plates 3 on the working rod 2 is realized by connecting the spring 5, and the limiting The position plate 3 is provided with a socket hole 31 for the pipeline to penetrate, and the end of the working rod 2 away from the body 1 is screwed with a support rod 4 parallel to the limit plate 3. The semicircle support frame 41.

specific Embodiment approach

[0023] Specific implementation method: firstly, the pipe is wound on the working rod 2 and between the limiting plate 3 and the working rod 2 close to the body 1. After the pipe is wound several times, its volume increases, which produces a certain squeeze on the limiting plate 3 Pressure effect, when the pipe is embedded compactly and firmly between this distance, one end of the pipe will go through the insertion hole 31 of the limiting plate 3, reach the second limiting plate 3, and connect the two limiting plates 3 to continue the winding work, in this way to achieve the winding of the pipe, when the pipe passes through the last limit plate 3, twist the support rod 4, so that the pipe is embedded in the semicircular support frame 41, and make the pipe There is a certain angle between the socket hole 31, at this time, it can effectively prevent the end of the pipe from slipping from the socket hole 31, effectively realize the positioning effect on the working rod 2 of the pip...

Embodiment 2

[0026] Embodiment 2: A pipe coiling device used in electrostatic spraying equipment, the difference from Embodiment 1 is that, as figure 2 As shown, at this moment, a hinge 33 is fixedly arranged on the limiting plate 3 away from the body 1, and a cylindrical plug body 34 is fixedly arranged at the end of the hinge 33 away from the limiting plate 3, and the outer peripheral surface of the cylindrical plug body 34 It is covered with a water-absorbing cotton layer 341 , and at the same time, a plurality of cylindrical plugs 342 are slipped and socketed in the cylindrical plug body 34 .

[0027] Specific embodiments: under the action of the cylindrical plug body 34, the port of the pipeline can be dust-proofed, that is, when the port of the pipeline passes through the insertion hole 31 of the last limiting plate 3 and is fixed in position, it can be The cylindrical plug body 34 is plugged into the port of the pipeline. At this time, under the action of the water-absorbing cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com