A kind of washing equipment for preparing utensils with electrolyte solution for battery production

An electrolyte and utensil technology, which is applied in the field of utensil washing equipment for battery production electrolyte preparation, can solve the problems of incomplete washing and inconvenient washing, and achieve the effects of avoiding unclean washing, improving washing efficiency and comprehensive washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

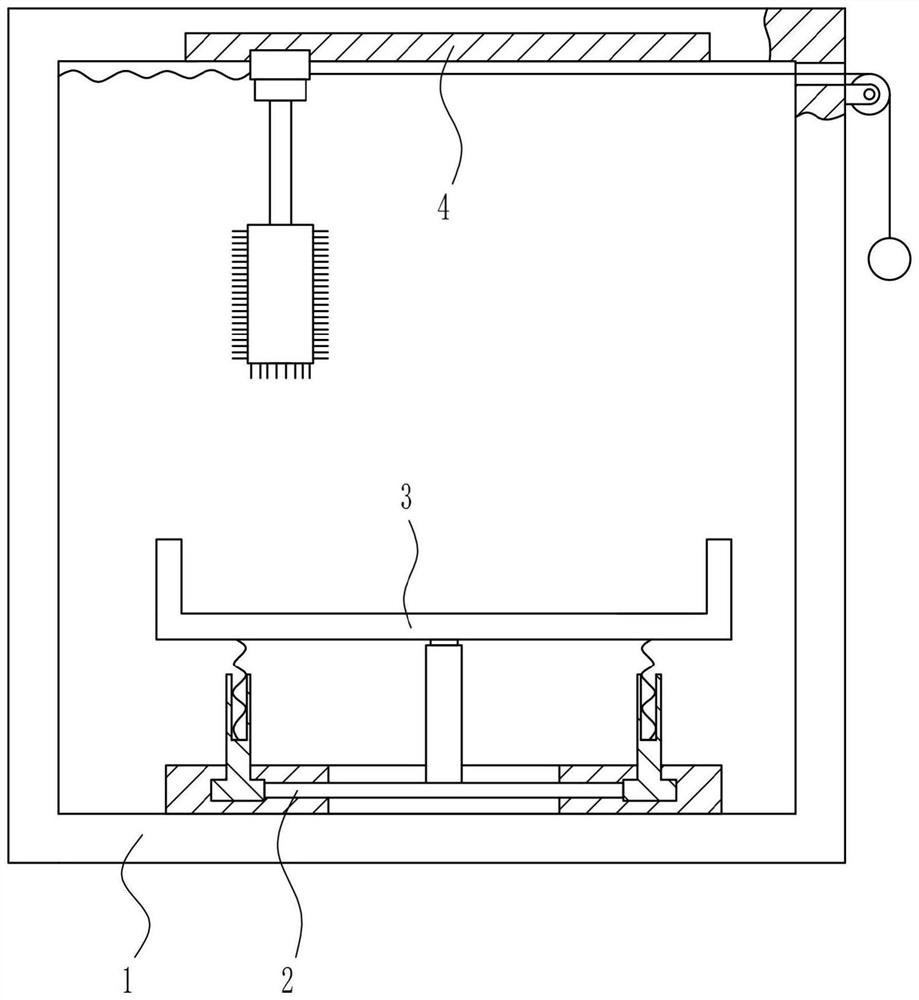

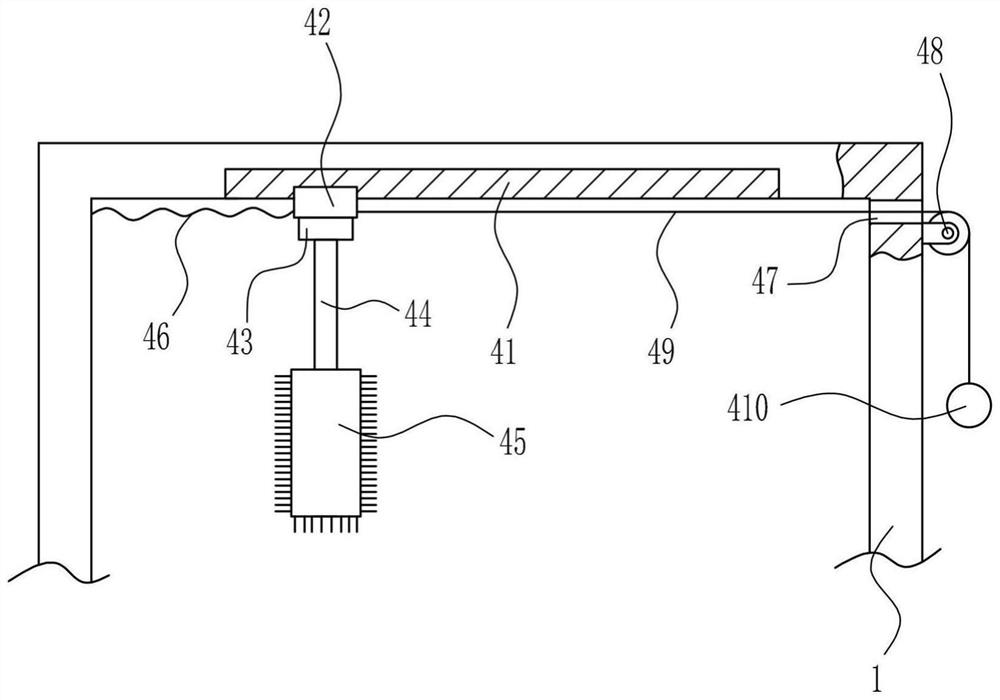

[0030] A battery producing an electrolyte formulation vessel scrubbing equipment, such as Figure 1-5 Shown, comprises a frame 1, the rotary device 2, the frame 3 and the washing unit 4, the mounting bracket is provided with a rotary bottom center apparatus 2, the top of the housing 2 is provided with rotating means 3, the top of the mounting bracket 1 is provided with brushing device 4.

Embodiment 2

[0032] A battery producing an electrolyte formulation vessel scrubbing equipment, such asFigure 1-5 Shown, comprises a frame 1, the rotary device 2, the frame 3 and the washing unit 4, the mounting bracket is provided with a rotary bottom center apparatus 2, the top of the housing 2 is provided with rotating means 3, the top of the mounting bracket 1 is provided with brushing device 4.

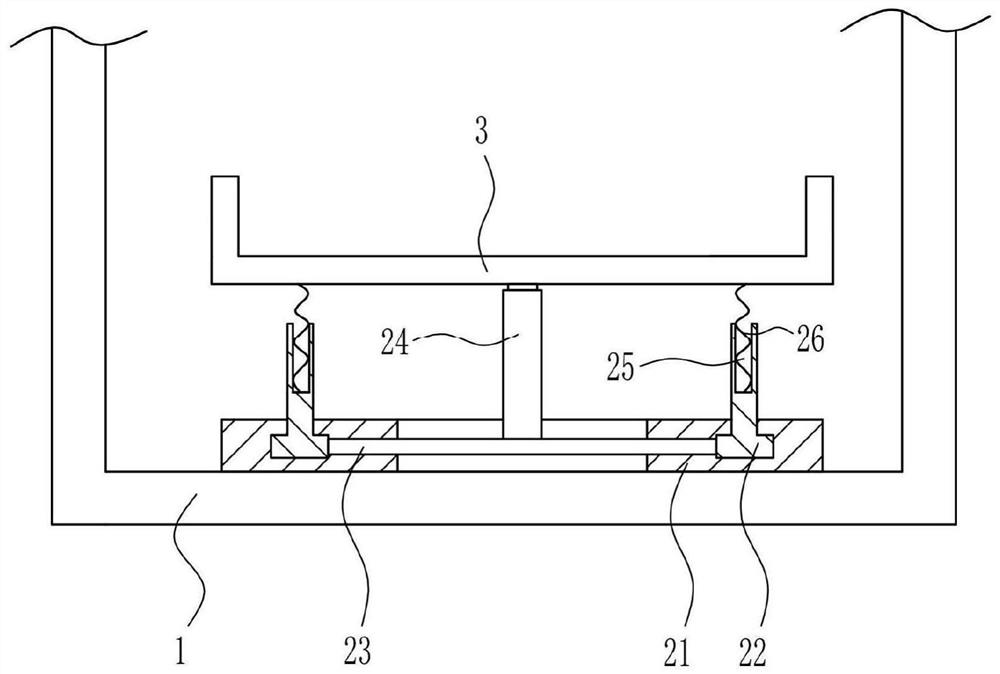

[0033] 2 rotation means 21 comprises an annular rail, a first slider 22, the connecting rod 23, an electric push rod 24 and the first spring 26, the mounting bracket is provided with an annular bottom center rail 21, the annular rail 21 symmetrically slidably connected to the first slider 22, is connected between the slider 22 inside the first connecting rod 23, the connecting rod 23 at the top center of the plunger 24 with electric, electric push rod 24 is connected to the top frame member 3, the first slide the top center block 22 are opened groove 25, the bottom of the recess 25 is connected to...

Embodiment 3

[0035] A battery producing an electrolyte formulation vessel scrubbing equipment, such as Figure 1-5 Shown, comprises a frame 1, the rotary device 2, the frame 3 and the washing unit 4, the mounting bracket is provided with a rotary bottom center apparatus 2, the top of the housing 2 is provided with rotating means 3, the top of the mounting bracket 1 is provided with brushing device 4.

[0036] 2 rotation means 21 comprises an annular rail, a first slider 22, the connecting rod 23, an electric push rod 24 and the first spring 26, the mounting bracket is provided with an annular bottom center rail 21, the annular rail 21 symmetrically slidably connected to the first slider 22, is connected between the slider 22 inside the first connecting rod 23, the connecting rod 23 at the top center of the plunger 24 with electric, electric push rod 24 is connected to the top frame member 3, the first slide the top center block 22 are opened groove 25, the bottom of the recess 25 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com