Storage battery bus-bar forming device

A battery and forming mold technology, applied in the battery field, can solve the problems of poor busbar forming effect and difficult quality control, and achieve the effect of improving casting and welding efficiency and saving lead liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

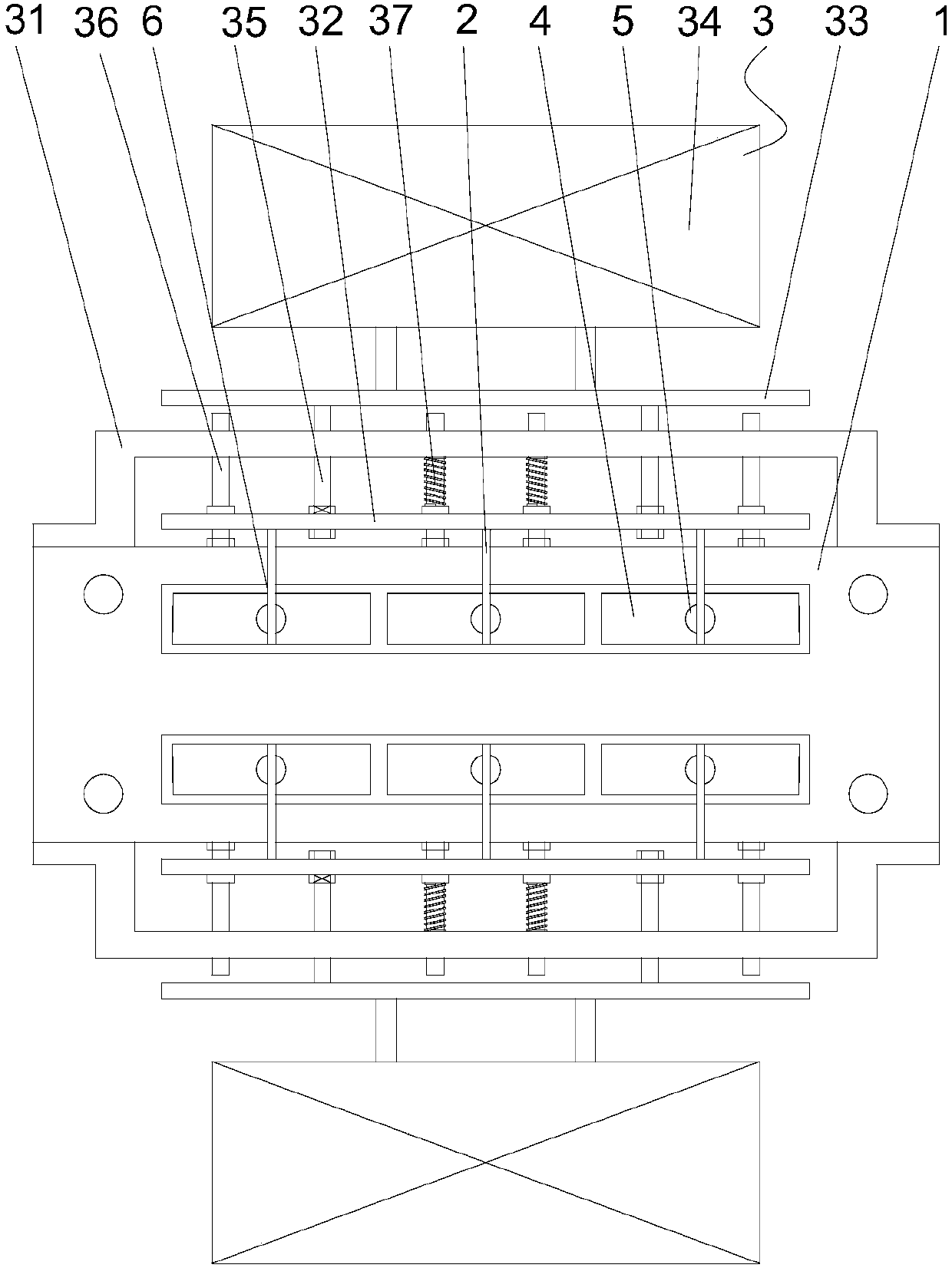

[0017] Such as figure 1 As shown, the present invention discloses a battery busbar forming device, which includes a forming mold 1, a separator 2 and a power unit 3, and the forming mold 1 is provided with several pairs of busbar grooves 4, and each pair of busbar grooves 4 passes through a bridge hole 5 are connected and distributed symmetrically, the depth of the bridge hole 5 is greater than the depth of the busbar groove 4, the forming mold 1 is provided with a slot 6 corresponding to the bridge hole 5, and a separator 2 is inserted in the slot 6, and one end of the separator 2 is located in the bridge hole 5, the other end of the separator 2 protrudes from the outer side of the molding die 1, the other end of the separator 2 is fixedly connected with the power unit 3 and moves with the power unit 3, the depth of the slot 6 is less than the depth of the bridge hole 5, and its characteristics In that: the power device 3 includes a bow-shaped fixed frame 31, a first connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com