Transfer trolley for handling automobile rear axle assembly

A technology for rear axles and transfer vehicles of automobiles, applied in the field of transfer vehicles, which can solve the problems of increasing the lateral size of transfer vehicles, complex structure of the traction frame, and inconvenient assembly operation, etc., and achieves easy processing and assembly, simple structure, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

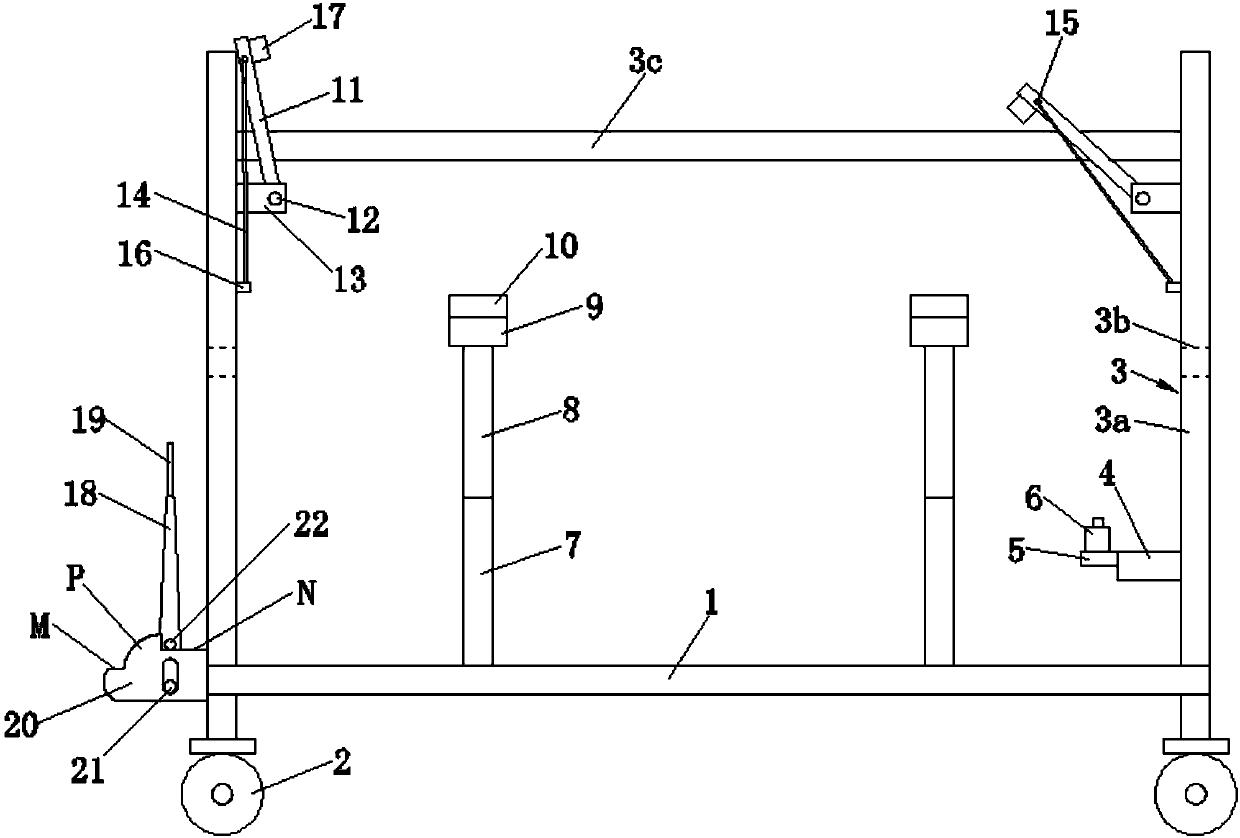

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

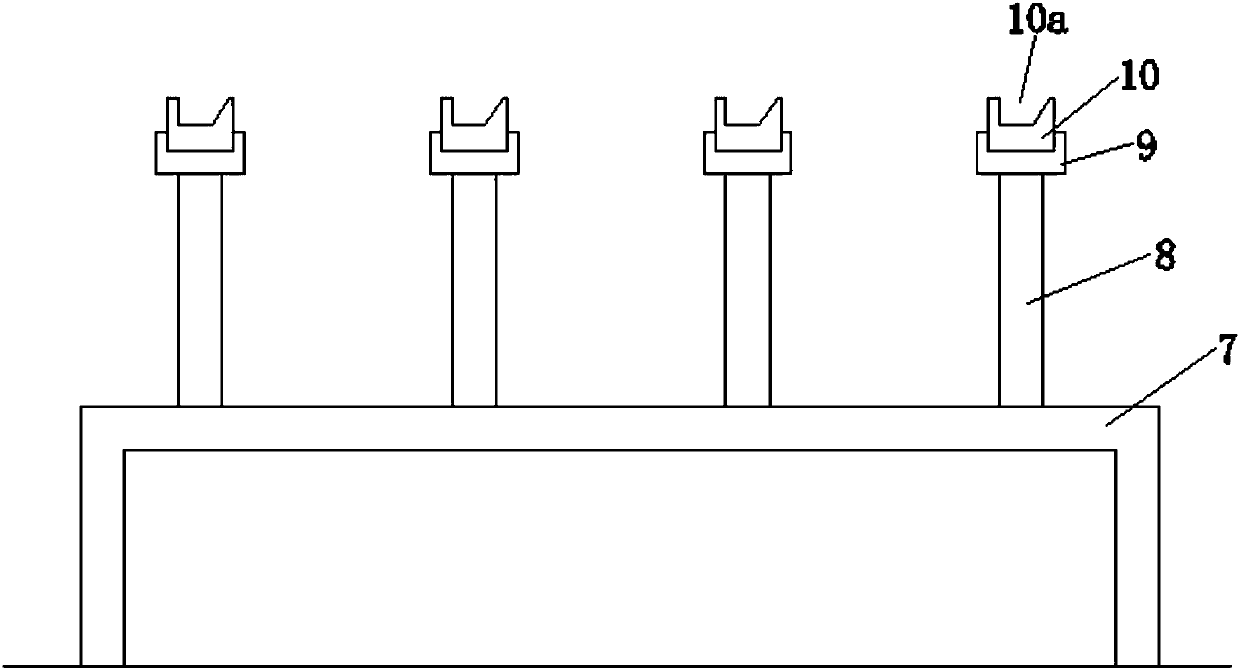

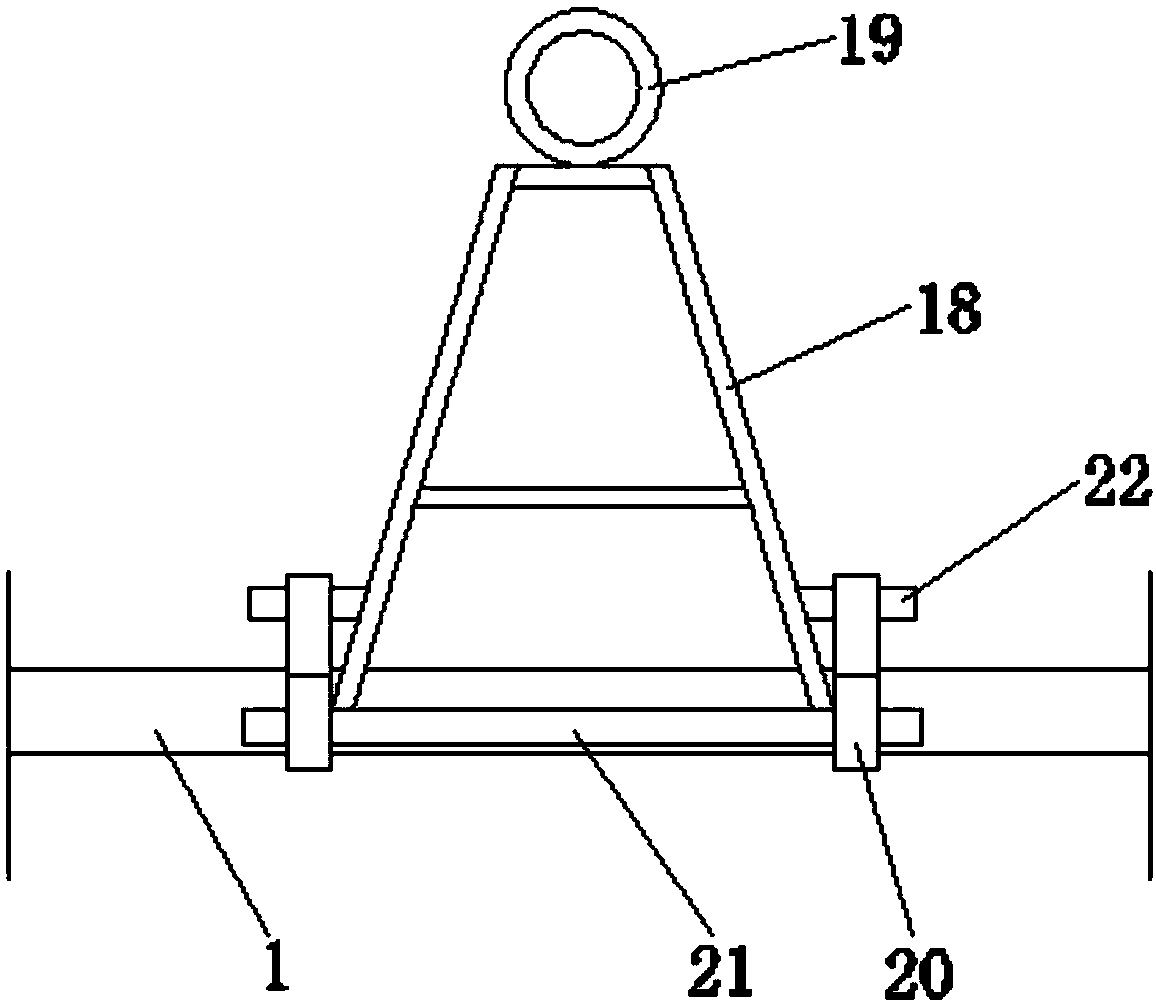

[0023] like figure 1 , figure 2 As shown, the transfer car of the car rear axle assembly has an underframe 1, which is a rectangular frame structure and is welded by rectangular tubes. Rollers 2 are installed at the four corners at the bottom of the chassis 1 to facilitate the movement of the transfer vehicle. Side frames 3 are arranged symmetrically at the left and right ends of the underframe 1. The side frames 3 are "H" shaped and are composed of two vertical tubes 3a parallel to each other and a vertical tube 3b connected between the middle parts of the two vertical tubes 3a. The standpipe 3a is perpendicular to the bottom frame 1, and the bottom end of the standpipe 3a is welded to the bottom frame 1. The vertical pipe 3b is perpendicular to the vertical pipe 3a, and the end of the vertical pipe 3b is welded with the corresponding vertical pipe 3a. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com