Cable protecting structure between propeller shaft and propeller hub of helicopter

A technology for protecting structures and helicopters, applied in aircraft lighting protectors, cable installation, aircraft electrostatic dischargers, etc., can solve problems such as fatigue fracture of lug attachments, large mutual movement deformation, etc., to solve fatigue fracture problems and improve fatigue characteristics, the effect of reducing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below.

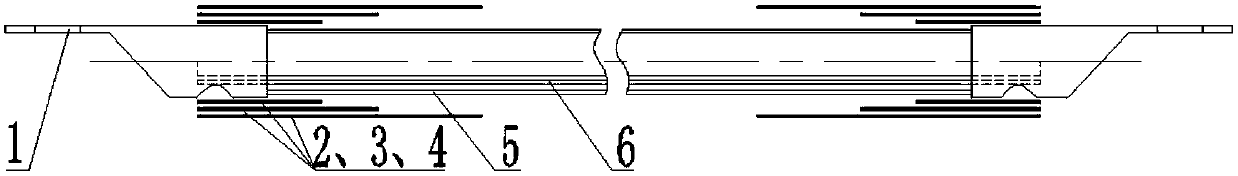

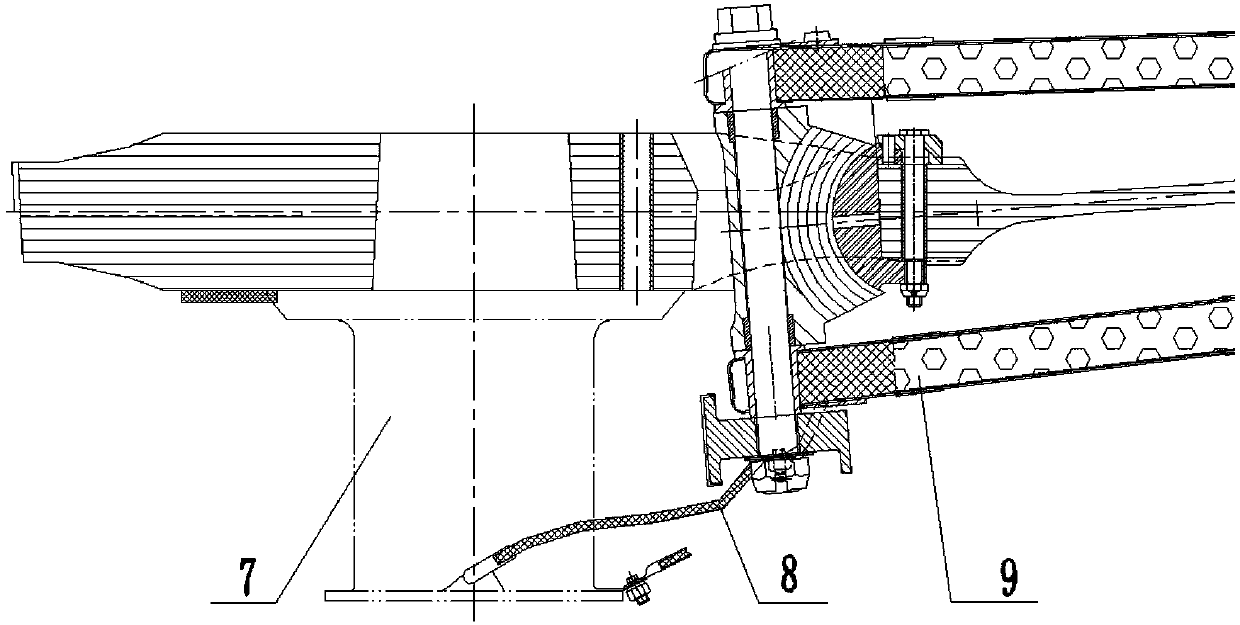

[0018] A cable protection structure between a helicopter hub and a propeller shaft is provided, the two ends of the cable are connection ends, one connection end is connected to the propeller hub, and the other connection end is connected to the propeller shaft; the cable belt With insulating sleeve;

[0019] Three-layer heat-shrinkable sleeves are set on both connection ends of the cable, and the lengths of the inner heat-shrinkable sleeve, the middle layer heat-shrinkable sleeve and the outer layer heat-shrinkable sleeve gradually increase; the insulating sleeve is made of soft polyethylene tube, the inner heat-shrinkable sleeve, the middle layer heat-shrinkable sleeve and the outer heat-shrinkable sleeve are all rubber sleeves; the two connecting ends of the cable are ground connection ends; the inner heat-shrinkable sleeve The length is 55mm; the length of the heat-shrinkable sleeve of the middle la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com