A light-weight polypropylene-plant fiber composite and a preparing method thereof

A plant fiber and composite material technology, applied in the field of lightweight polypropylene plant fiber composite material and its preparation, can solve the problems of improper selection of chemical foaming agent, high cost of foaming agent, environmental pollution, etc., and achieve good development prospects, Good sound absorption and heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

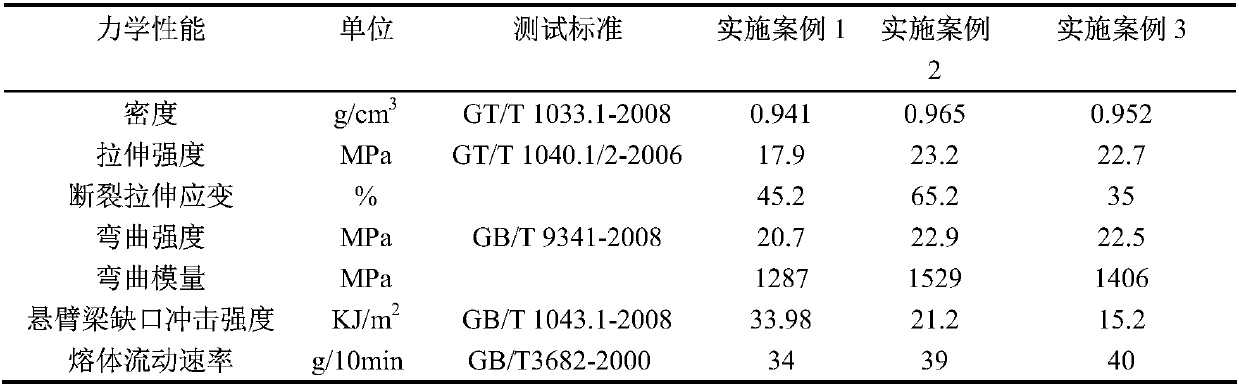

Embodiment 1

[0015] Embodiment 1 of the present invention: lightweight polypropylene plant fiber composite material, calculated in parts by mass, including 60 parts of high melt strength polypropylene, 20 parts of plant fiber, 18 parts of polyethylene, 1 part of nucleating agent and dispersant 1 part is the preparation material. The polypropylene is a high melt strength polypropylene, its melt index (230°C / 2.16kg) is 1.3g / 10min, and its melt tension (230°C) is 20g.

[0016] The preparation method of lightweight polypropylene plant fiber composite material comprises the following steps:

[0017] 1) Take each component according to the above-mentioned parts by mass, mix polypropylene, plant fiber, polyethylene, nucleating agent and dispersant to make it fully dispersed; wherein, the plant fiber is taken from the stalk of the crop, and it is mixed before mixing. The plant fibers were pre-dried at 80°C for 1.5h.

[0018] 2) Add the blend in step 1) to a twin-screw extruder for extrusion. The...

Embodiment 2

[0020] Embodiment 2 of the present invention: Lightweight polypropylene plant fiber composite material, calculated in parts by mass, including 70 parts of high melt strength polypropylene, 15 parts of plant fiber, 14 parts of polyethylene and 1 part of nucleating agent as raw materials for preparation . Described polypropylene is high-melt strength polypropylene, and its melt index (230 ℃ / 2.16kg) is 2.5g / 10min, and melt tension (230 ℃) is 18g

[0021] The preparation method of lightweight polypropylene plant fiber composite material comprises the following steps:

[0022] 1) Take each component according to the above-mentioned parts by mass, mix polypropylene, plant fiber, polyethylene, nucleating agent and dispersant to make it fully dispersed; wherein, the plant fiber is taken from the stalk of the crop, and it is mixed before mixing. The plant fibers were pre-dried at 80°C for 1.5h.

[0023] 2) Add the blend in step 1) to a twin-screw extruder for extrusion. The temperatu...

Embodiment 3

[0025] Embodiment 3 of the present invention: lightweight polypropylene plant fiber composite material, calculated in parts by mass, including 70 parts of high melt strength polypropylene, 18 parts of plant fiber, 10 parts of polyethylene, 1 part of nucleating agent and dispersant 1 part is the preparation material. Described polypropylene is high-melt strength polypropylene, and its melt index (230 ℃ / 2.16kg) is 1.5g / 10min, and melt tension (230 ℃) is 15g

[0026] The preparation method of lightweight polypropylene plant fiber composite material comprises the following steps:

[0027] 1) Take each component according to the above-mentioned parts by mass, mix polypropylene, plant fiber, polyethylene, nucleating agent and dispersant to make it fully dispersed; wherein, the plant fiber is taken from the stalk of the crop, and it is mixed before mixing. The plant fibers were pre-dried at 80°C for 1.5h.

[0028] 2) Add the blend in step 1) to a twin-screw extruder for extrusion. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com