Microfoamed polypropylene and plant-fiber composite material and preparation method thereof

A plant fiber and composite material technology, which is applied in the field of micro-foamed polypropylene plant fiber composite material and its preparation, can solve the problems of difficulty in foaming and gas retention, and achieves high foaming ratio, uniform cell distribution, and low cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Preparation of micro-foamed polypropylene plant fiber composite material

[0016] (1) Weigh by mass: 10 parts of high-strength polypropylene, 54 parts of high-fluidity polypropylene, 25 parts of plant fiber, 10 parts of polyethylene, 0.5 parts of nucleating agent calcium carbonate and dispersant of ethylene stearic acid Amide 0.5 part.

[0017] (2) Mix the components in the step (1) with a mixer, add them into a twin-screw extruder to extrude and granulate, and then prepare the plant fiber composite polypropylene matrix.

[0018] (3) Add 2 parts of NaHCO in the plant fiber composite polypropylene matrix prepared in step (2) 3 , mixed evenly, and the micro-foaming plant fiber composite polypropylene material was prepared by using an injection molding process.

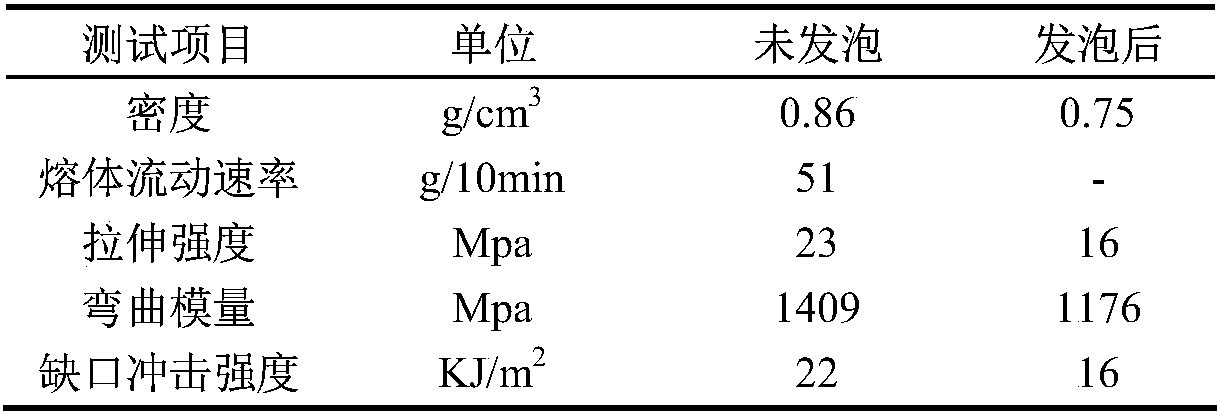

[0019] The mechanical properties of unfoamed and foamed materials were tested respectively, and the results are shown in Table 1.

Embodiment 2

[0020] Embodiment 2: Preparation of micro-foamed polypropylene plant fiber composite material

[0021] (1) Weighing by mass: 12 parts of high-strength polypropylene, 50 parts of high-fluidity polypropylene, 29 parts of plant fiber, 8 parts of polyethylene, 0.5 parts of nucleating agent calcium carbonate and dispersant of ethylene stearic acid Amide 0.5 parts.

[0022] (2) Mix the components in the step (1) with a mixer, add them into a twin-screw extruder to extrude and granulate, and then prepare the plant fiber composite polypropylene matrix.

[0023] (3) Add 2 parts of foaming agent to the plant fiber composite polypropylene matrix prepared in step (2), mix well, and use the injection molding process to prepare the slightly foamed plant fiber composite polypropylene material.

[0024] The mechanical properties of unfoamed and foamed materials were tested respectively, and the results are shown in Table 2.

Embodiment 3

[0025] Embodiment 3: Preparation of micro-foamed polypropylene plant fiber composite material

[0026] (1) Weigh by mass: 15 parts of high-strength polypropylene, 54 parts of high-fluidity polypropylene, 20 parts of plant fiber, 10 parts of polyethylene, 0.6 part of nucleating agent calcium carbonate and dispersant of ethylene stearic acid Amide 0.4 parts.

[0027] (2) Mix the components in the step (1) with a mixer, add them into a twin-screw extruder to extrude and granulate, and then prepare the plant fiber composite polypropylene matrix.

[0028] (3) Add 2 parts of foaming agent to the plant fiber composite polypropylene matrix prepared in step (2), mix well, and use the injection molding process to prepare the slightly foamed plant fiber composite polypropylene material.

[0029] The mechanical properties of unfoamed and foamed materials were tested respectively, and the results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com