Anti-seismic structure for shear beam and shear beam

A technology for seismic structures and structural holes, applied in truss structures, girders, earthquake-proof and other directions, can solve the problems of affecting the safe use of shear beam structures, poor deflection at structural joints, and poor appearance of shear beams, and achieve fatigue resistance. Good performance, high installation accuracy, and the effect of improving seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

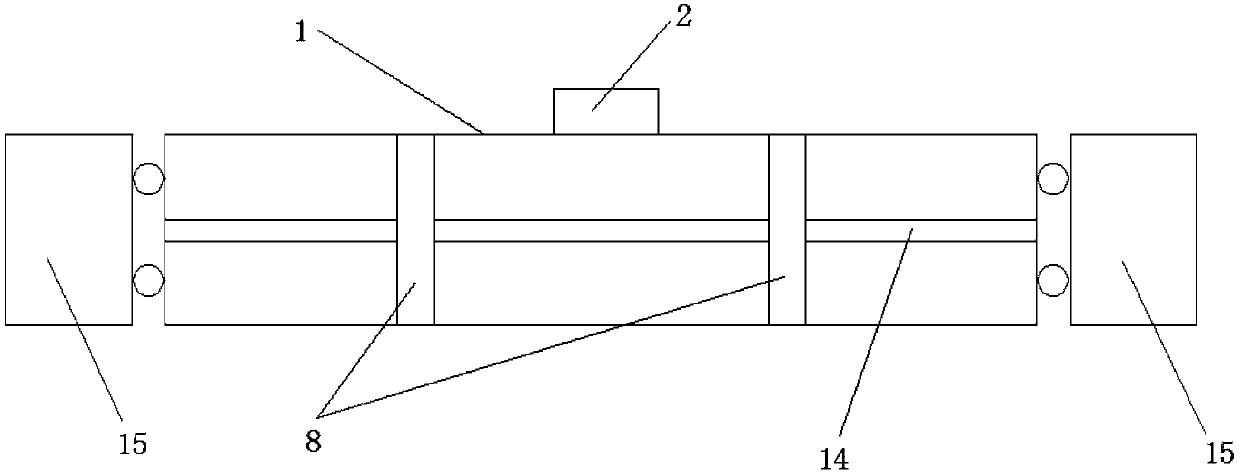

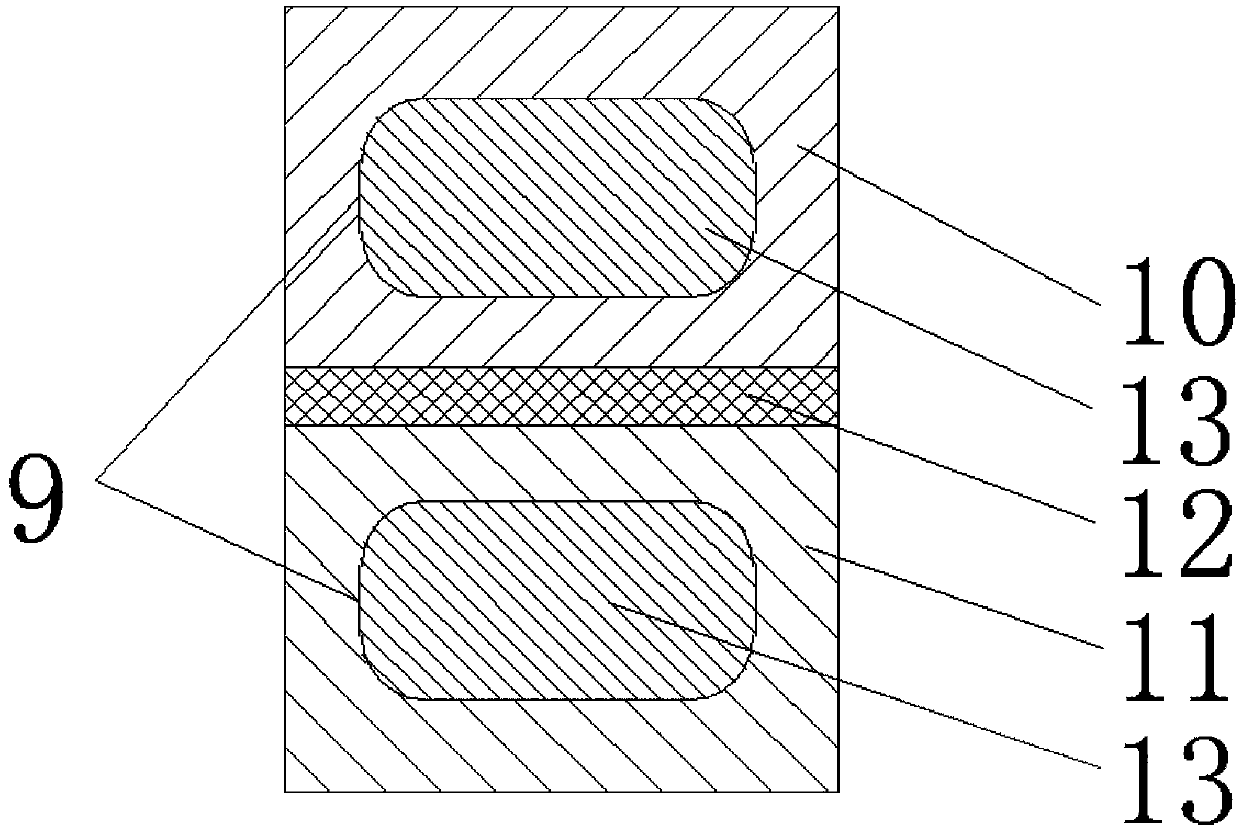

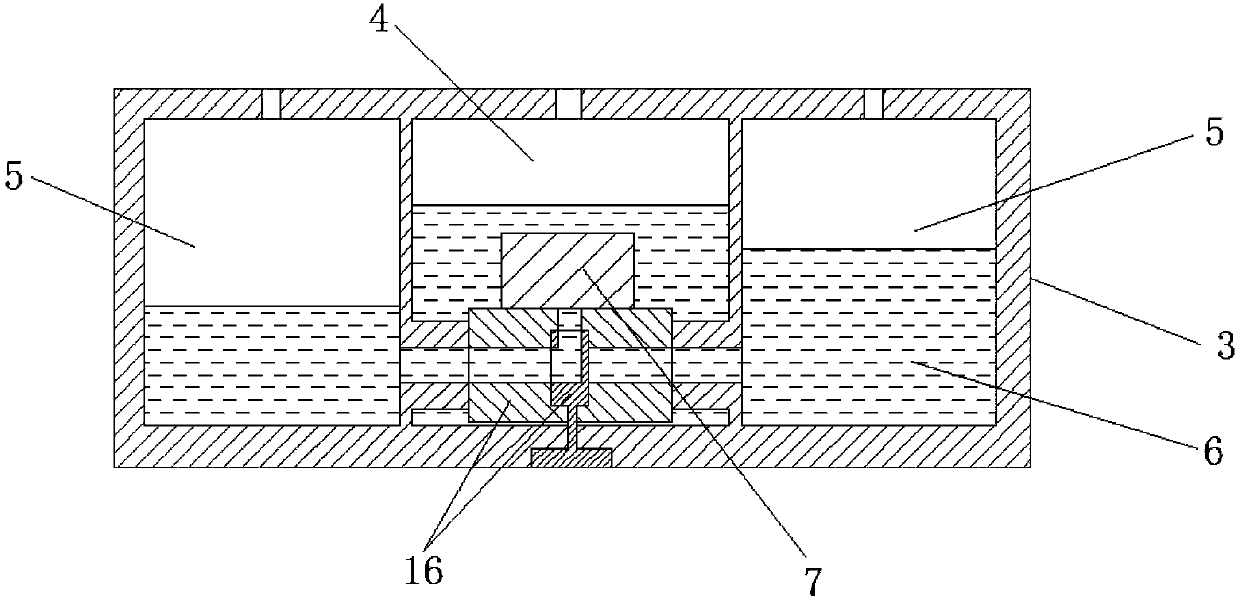

[0029] see Figure 1 to Figure 4 As shown, an anti-seismic structure for a shear beam includes a beam body 1, and an anti-seismic frequency modulation mechanism 2 is provided on the upper surface of the beam body for changing the natural frequency of the beam body to avoid resonance with seismic waves Frequency section to improve the anti-seismic performance of the beam body; the anti-seismic frequency modulation mechanism includes a housing 3, and a balance chamber 4 and two damping chambers 5 are arranged in the housing, and the balance chamber is used for carrying out When the frequency is adjusted, excess damping liquid is stored, each of the damping chambers is filled with damping liquid 6, and the damping chambers are used to adjust the overall damping of the beam body, and each of the damping chambers passes a common power The pump 7 communicates with the balance chamber, and the power pump communicates with each of the damping chambers through the battery valve 16; the...

Embodiment 2

[0032] Embodiment 2. This embodiment is improved on the basis of Embodiment 1. The content described in Embodiment 1 is also included in this embodiment, and will not be repeated here.

[0033] see Figure 1 to Figure 4 As shown, a shear beam includes the described anti-seismic structure for the shear beam; the described anti-seismic structure for the shear beam includes a beam body 1, and the upper surface of the beam body is provided with an anti-seismic frequency modulation Mechanism 2 is used to change the natural frequency of the beam body to avoid the resonant frequency range with seismic waves to improve the seismic performance of the beam body; the anti-seismic frequency modulation mechanism includes a housing 3, and a balance cavity is arranged in the housing chamber 4 and two damping chambers 5, the balance chamber is used to store excess damping liquid during frequency adjustment, each of the damping chambers is filled with damping liquid 6, and the damping chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com