Rubber damper and connecting rod buffering base thereof

A damper, rubber technology, applied in the direction of springs/shock absorbers, springs made of plastic materials, springs, etc., to achieve the effects of wide adaptability, increased damage safety, and good use safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Attached below Figure 1~2 The present invention will be described in detail.

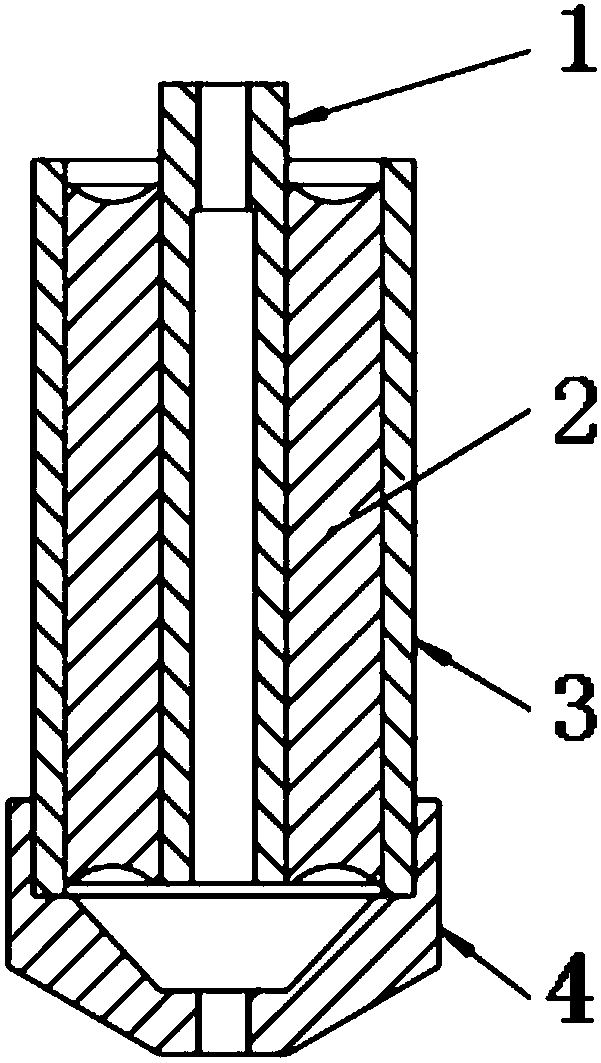

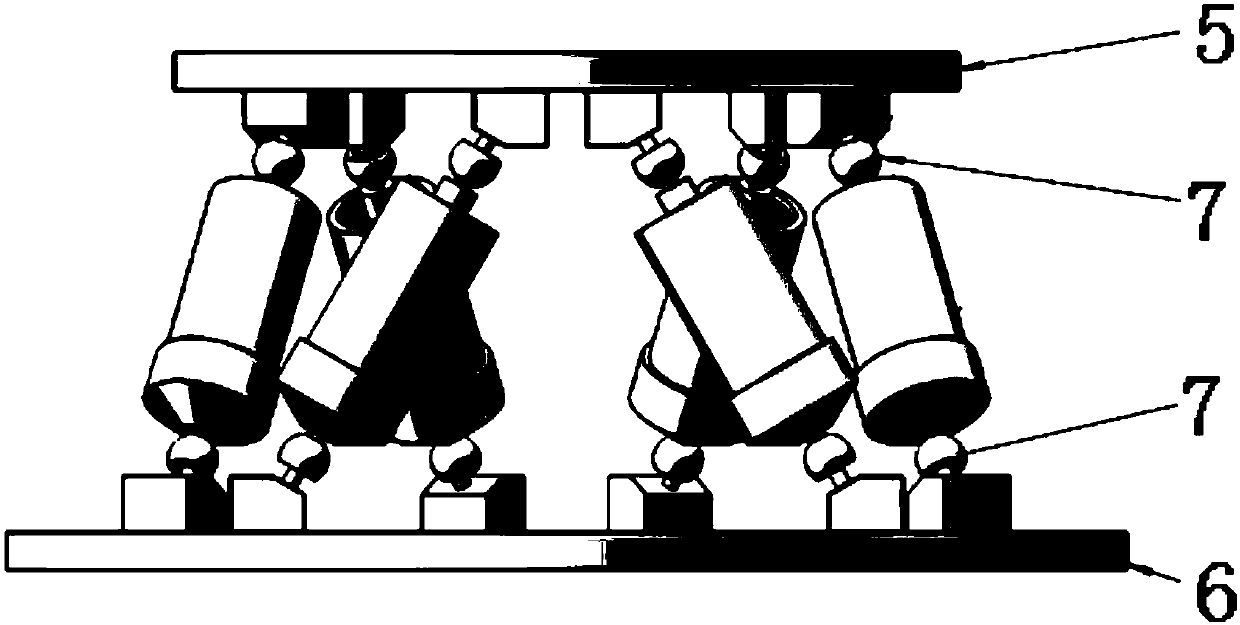

[0019] A rubber damper is provided, including an inner cylinder 1, an outer cylinder 3, a rubber buffer block 2 and a base 4; the outer cylinder is set outside the inner cylinder, and the rubber buffer is connected between the inner cylinder and the outer cylinder block, the rubber buffer block is thermally vulcanized and bonded to the inner wall of the outer cylinder, and the rubber buffer block is thermally vulcanized and bonded to the outer wall of the inner cylinder; the base is fixedly connected to one end of the outer cylinder, and the base is used as the first connection end of the rubber damper; The inner cylinder protrudes from the other end of the outer cylinder as the second connecting end of the rubber damper; the mutual displacement between the inner cylinder and the outer cylinder causes elastic deformation of the rubber buffer block; the inner cylinder 1 and the outer cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com