Scale-depositing-resistant rapid heating module

A rapid heating and fouling technology, used in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of easy fouling, high temperature of the inner wall of the boiling water pipe, and easy peeling of the enamel layer. The effect of combining good and avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

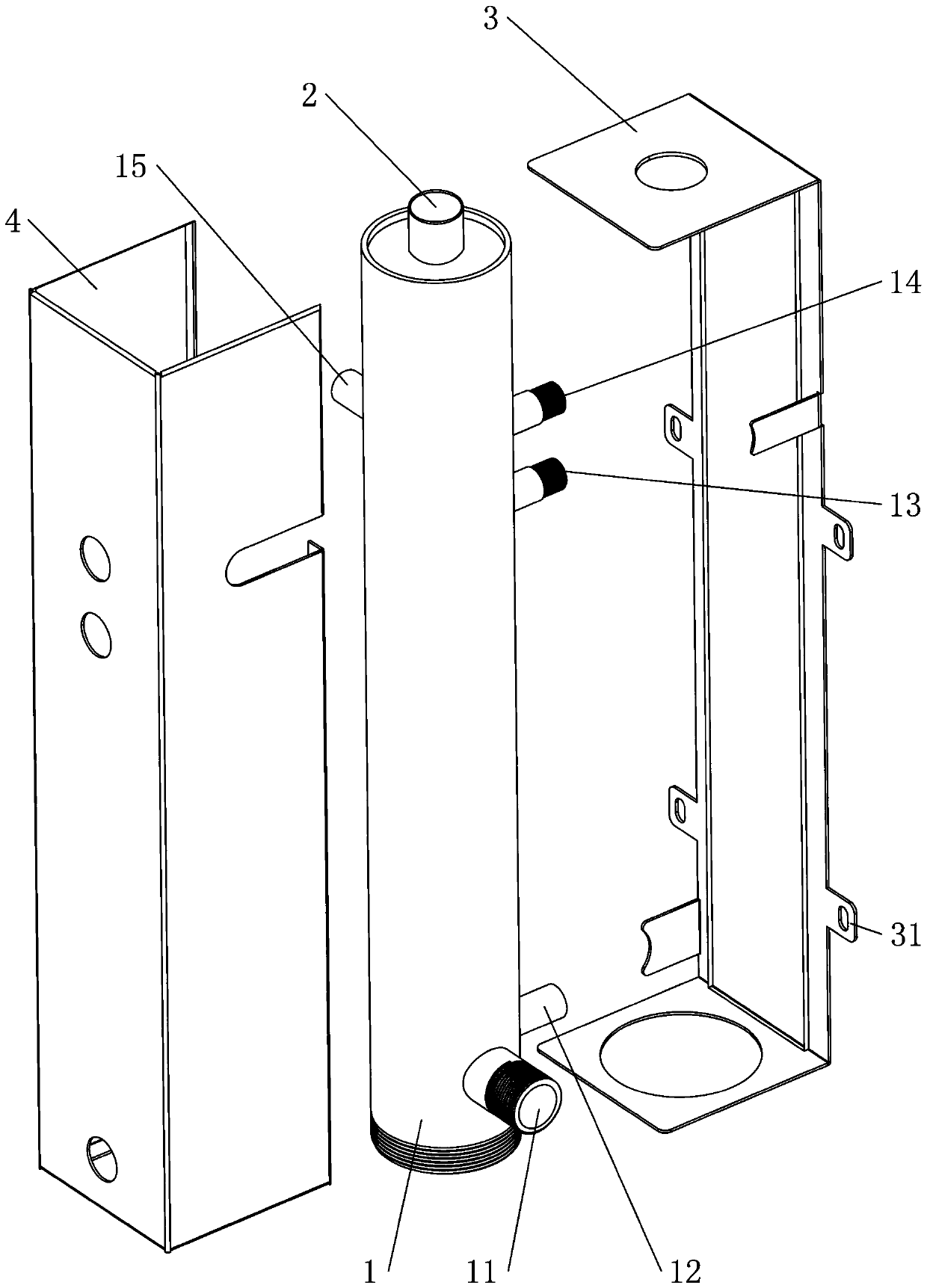

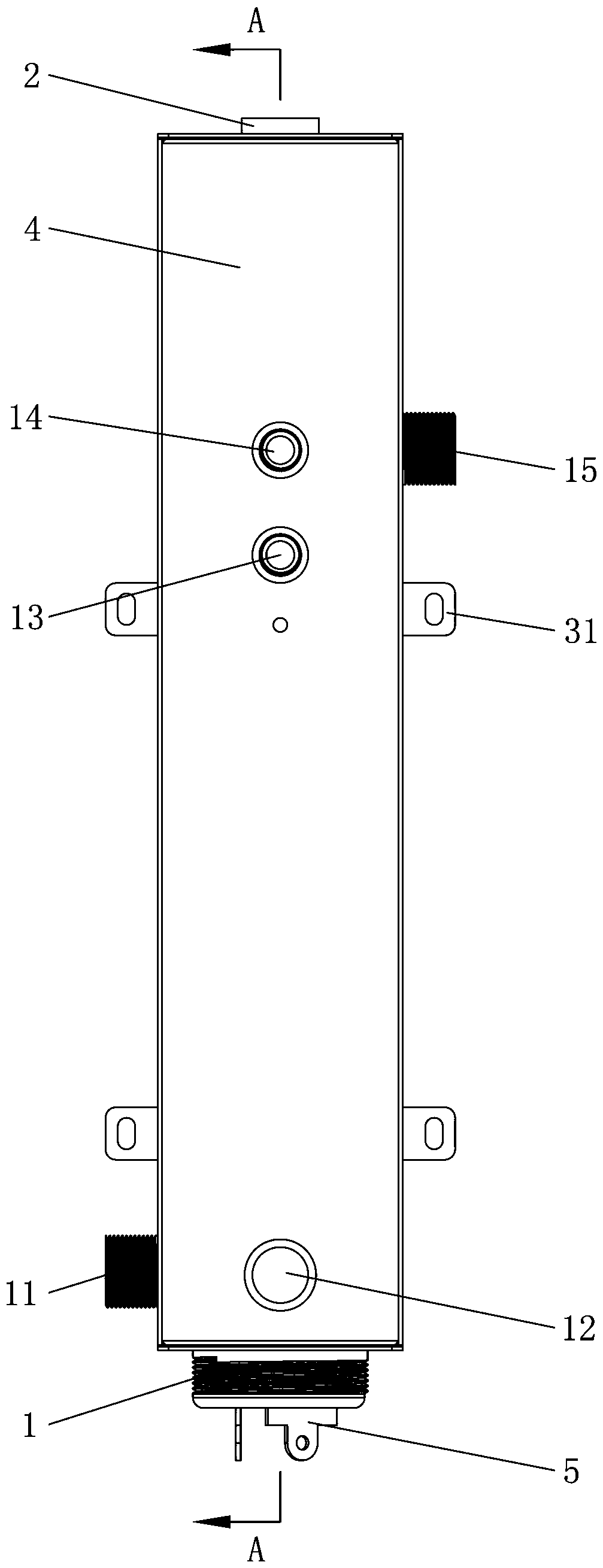

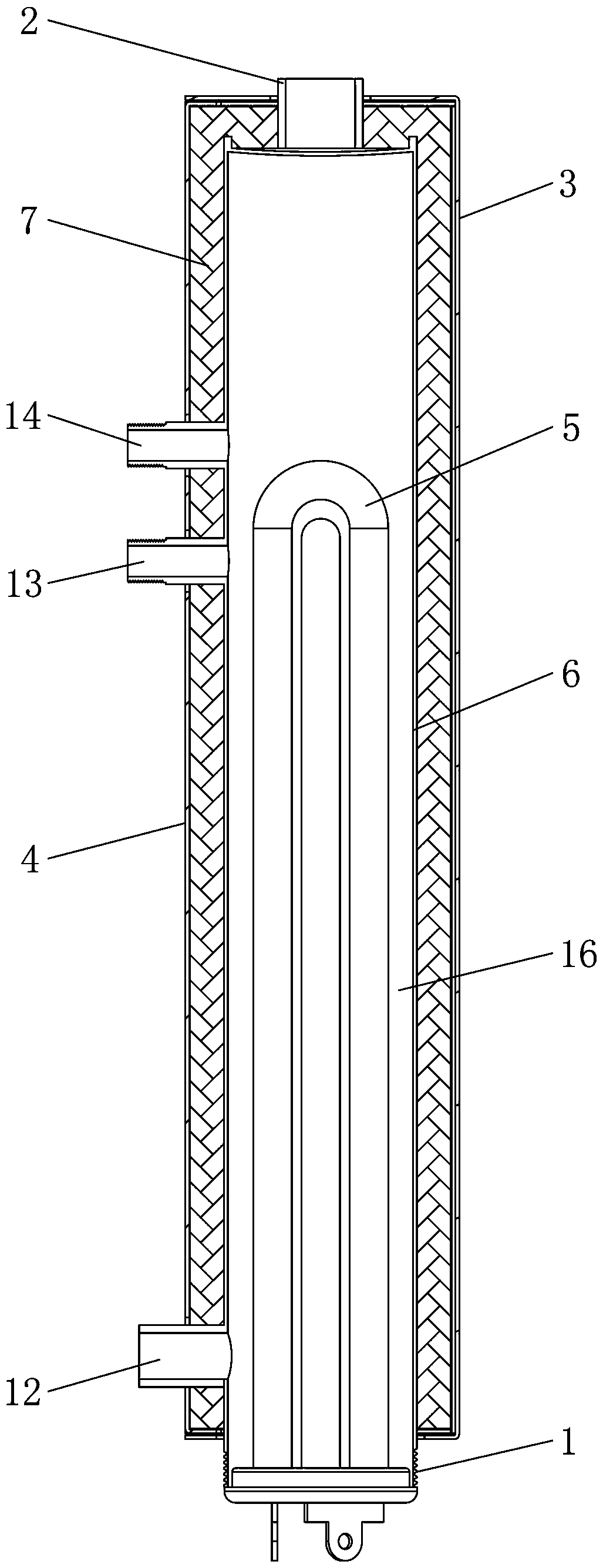

[0032] Embodiment one, see Figure 1 to Figure 5 As shown, an anti-fouling fast heating module, especially a warm water type fast heating module for anti-fouling, includes a water boiling pipe 1, a heating pipe 5 and a shell, and the water boiling pipe 1 is provided with a water boiling chamber 16. The heating pipe 5 extends from the bottom of the boiling water pipe 1 into the boiling water chamber 16. The water boiling chamber 16 is provided with a water inlet 12 corresponding to the lower end of the heating pipe 5, and the boiling water chamber 16 is provided with a water outlet 15 corresponding to the upper part of the heating pipe 5. The water boiling pipe 1 is arranged in the shell, the heat preservation layer 7 is arranged between the water boiling pipe 1 and the inner wall of the shell, the water outlet temperature sensor 14 is arranged above the water boiling chamber 16 corresponding to the heating pipe 5, and the water boiling chamber 16 corresponds to the heating pipe...

Embodiment 2

[0037] Embodiment two, see Figure 6 to Figure 11 As shown, an anti-fouling quick-heating module, especially an anti-fouling warm-open type quick-heating module, includes water boiling pipes, two water boiling pipes are provided, and water boiling chambers are respectively provided in each water boiling pipe. A heat pipe is arranged in the water boiling chamber, and the heat pipe extends into the water boiling chamber from the bottom of the water boiling pipe. The water-boiling pipes are arranged together in a shell, an insulation layer 7 is provided between the water-boiling pipes and the inner wall of the shell, and an outlet water temperature sensor is provided above the corresponding heating pipes of the water-boiling chamber. The wall surface of the water boiling chamber of the water boiling pipe is provided with a metal titanium anti-scaling coating 6 .

[0038] As a further solution, the water boiling pipe is provided with two pipes, which are the warm water boiling pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com