Sampling method and device for avoiding bracing of carriage

A technology of sampling device and compartment, which is applied in the direction of sampling device, etc., can solve the problems of being located above the coal surface or below the coal surface, sampling randomness, and difficult to pull tendon detection, so as to eliminate the risk of manual fraud and prevent Sampling Accidents, Impact Prevention Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

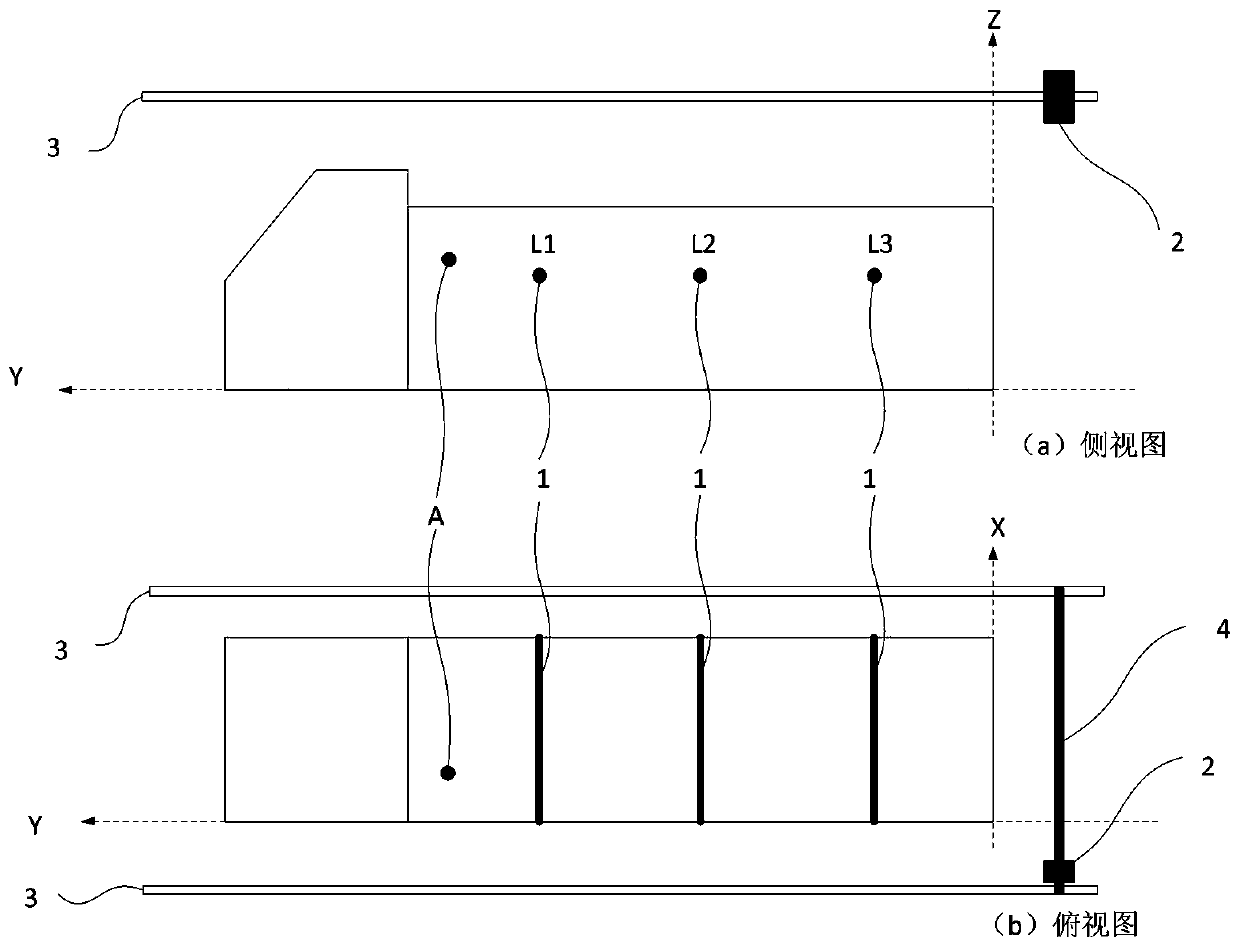

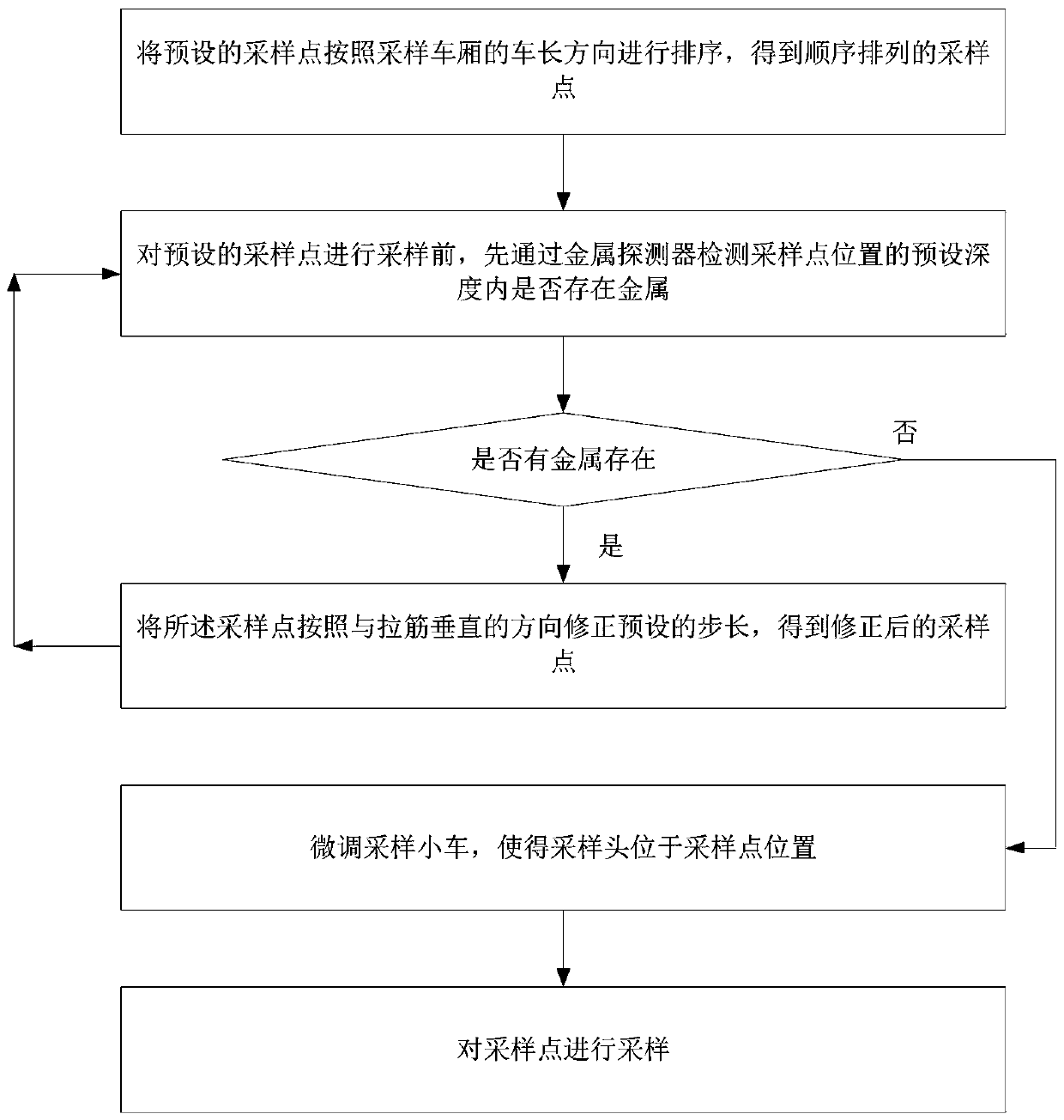

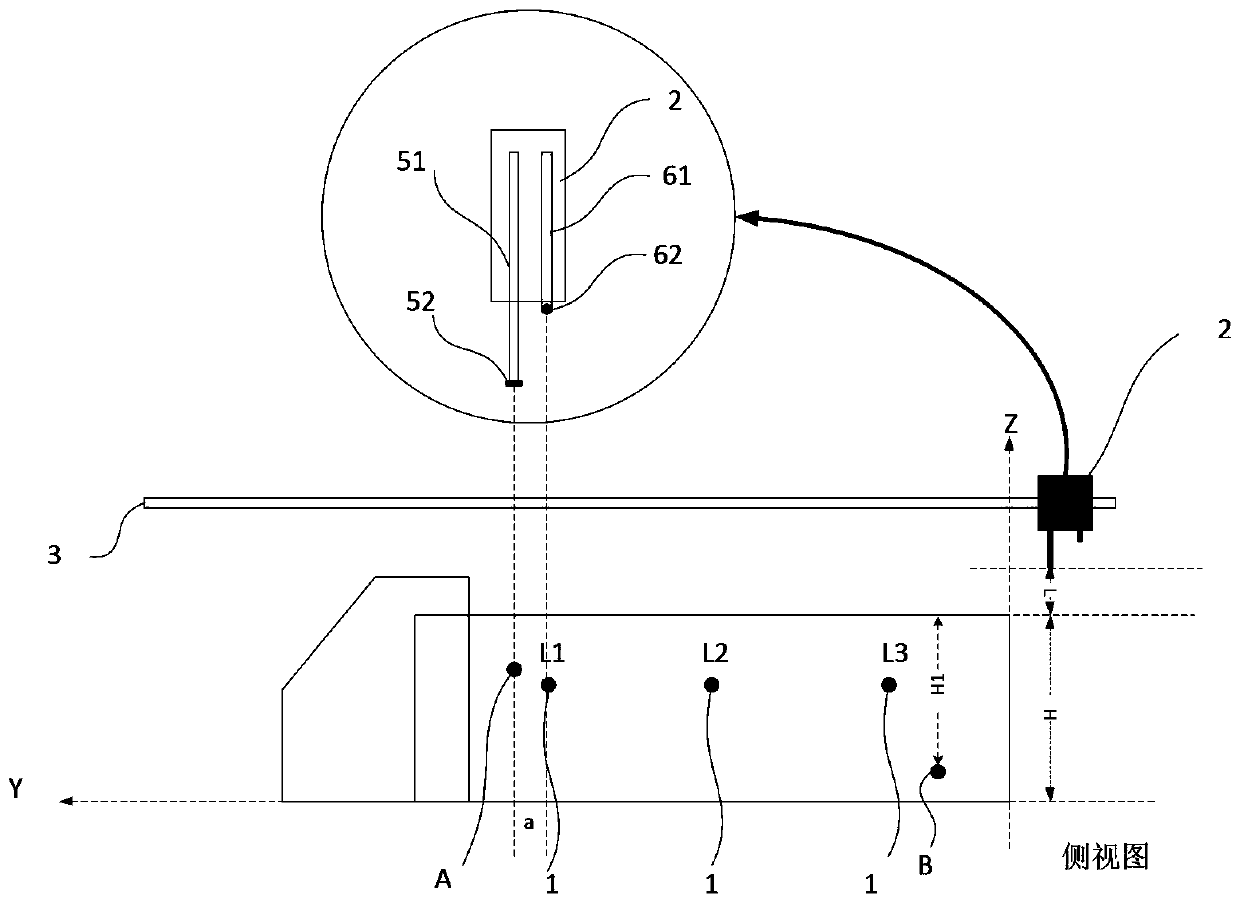

[0024] In the prior art, the process of automatically sampling coal samples in the compartment, such as figure 1 shown, where figure 1 (a) is a side view, figure 1 (b) is a top view. For the convenience of description, the XYZ coordinate system is used to describe the sampling three-dimensional space where the carriage is located. When the carriage stops at the sampling area, the sampling trolley can move along the longitudinal direction of the carriage through the Y guide rail, and the X guide rail can move along the transverse direction of the carriage. For the determined sampling point A, its coordinates are (x1, y1, z1), the sampling car is moved above the sampling point A through the Y-guiding rail and the X-guiding rail, and then the sampling car lowers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com