Numerical control machine tool drilling process power, energy consumption and energy-saving control method

A numerical control machine tool, energy-saving control technology, applied in program control, computer control, general control system, etc., to achieve the effect of high prediction accuracy, simple operation, accurate evaluation and energy-saving control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Now, the present invention is explained in detail in conjunction with the embodiments and the accompanying drawings.

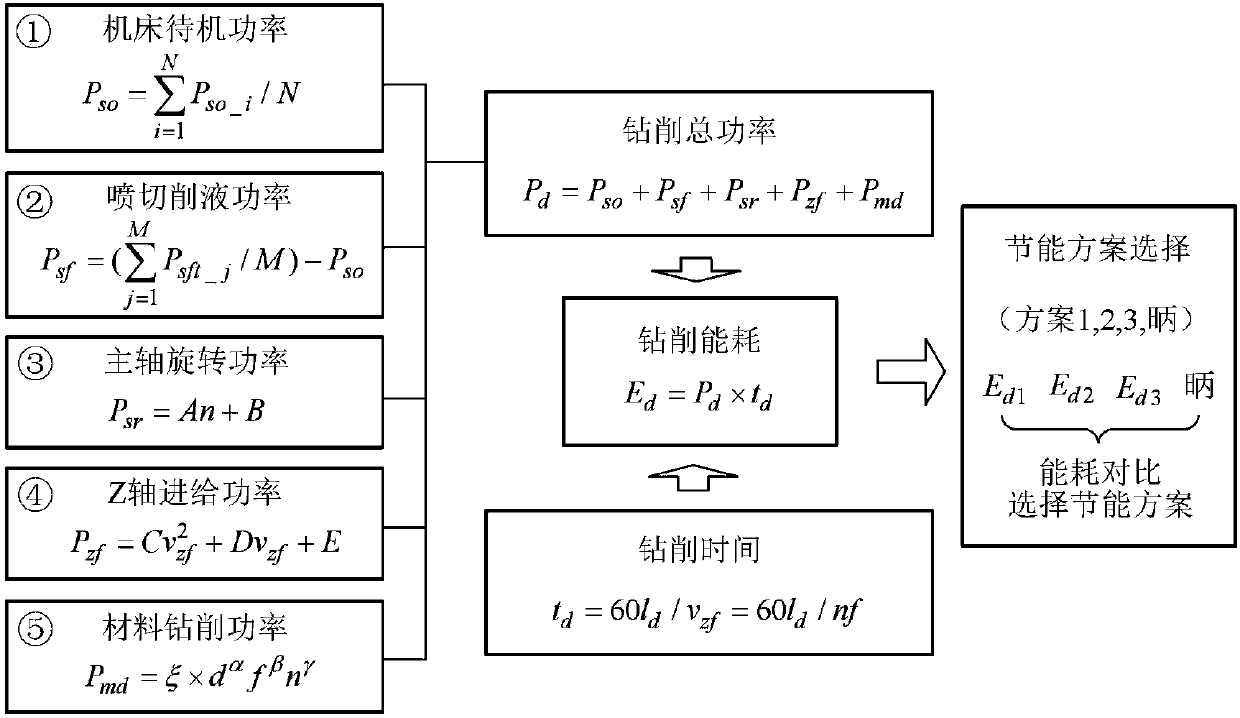

[0035] The invention proposes a numerical control machine tool drilling process power and energy consumption acquisition and energy-saving control method. Such as figure 1 As shown, the method is to decompose the total power of the CNC machine tool drilling process into five parts: machine tool standby power, spray cutting fluid power, spindle rotation power, Z-axis feed power and material drilling power, and perform a power model for each part Construction, so as to establish the total power model of the CNC machine tool drilling process; and then through the establishment of the drilling time model, the energy consumption of the CNC machine tool during the drilling process is obtained, and energy-saving control is carried out.

[0036] 1. Total power acquisition of CNC machine tool drilling

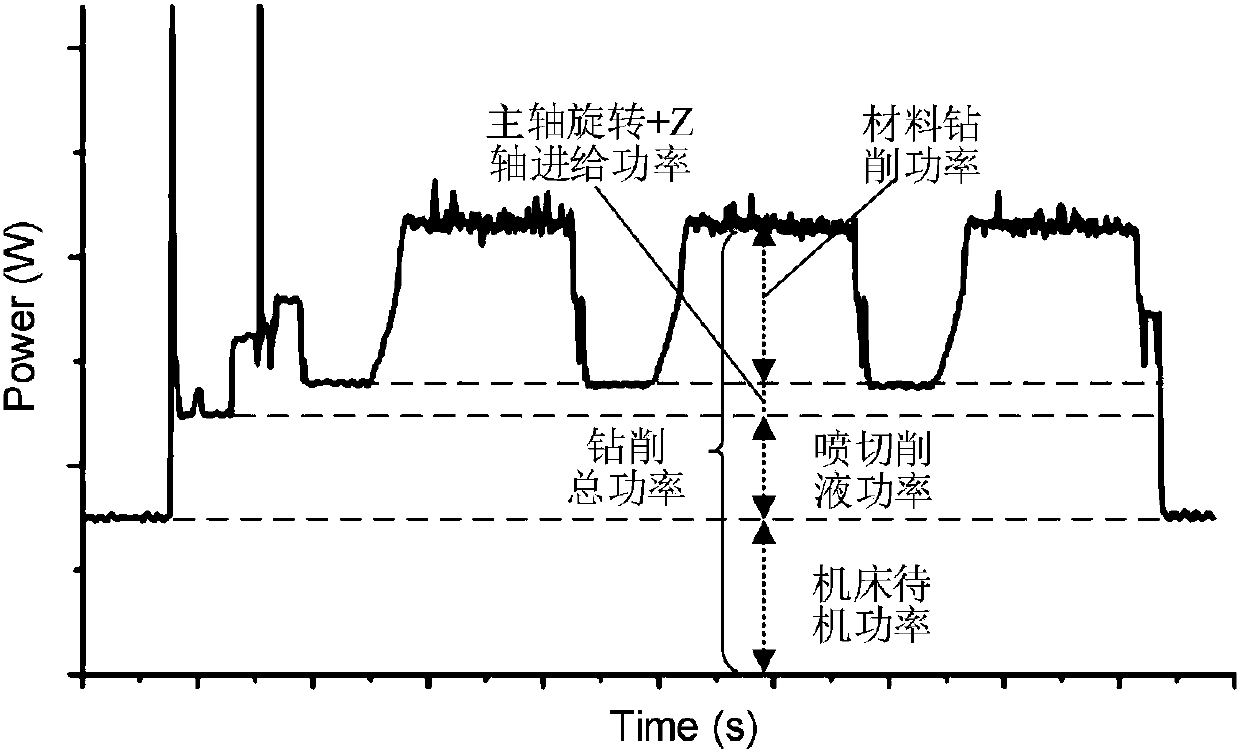

[0037] Such as figure 2 As shown, the total power calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com