Calculation Algorithms of Initial Stiffness and Plastic Failure Strength of Variable Section Metal Lattice Structure

A metal lattice, initial stiffness technology, applied in the direction of calculation, computer-aided design, design optimization/simulation, etc., can solve problems such as inability to predict initial stiffness and plastic failure strength, hindering structural mechanical properties, inapplicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] 1. Structural design of variable section rods

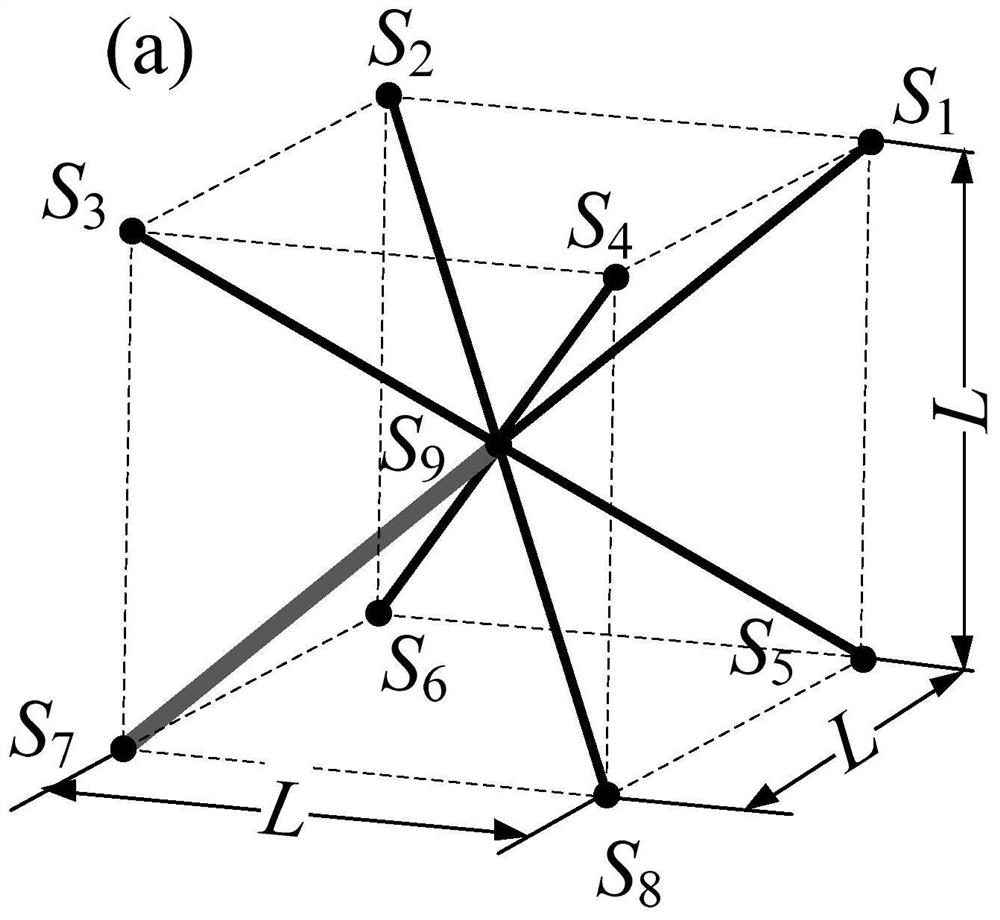

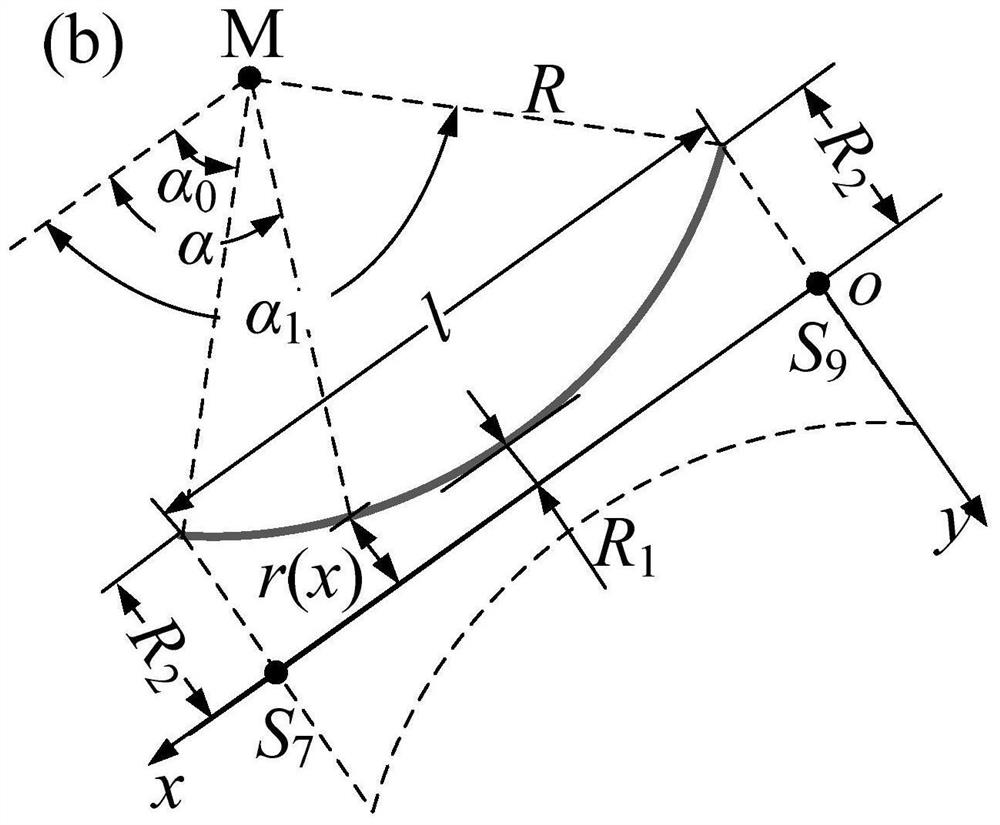

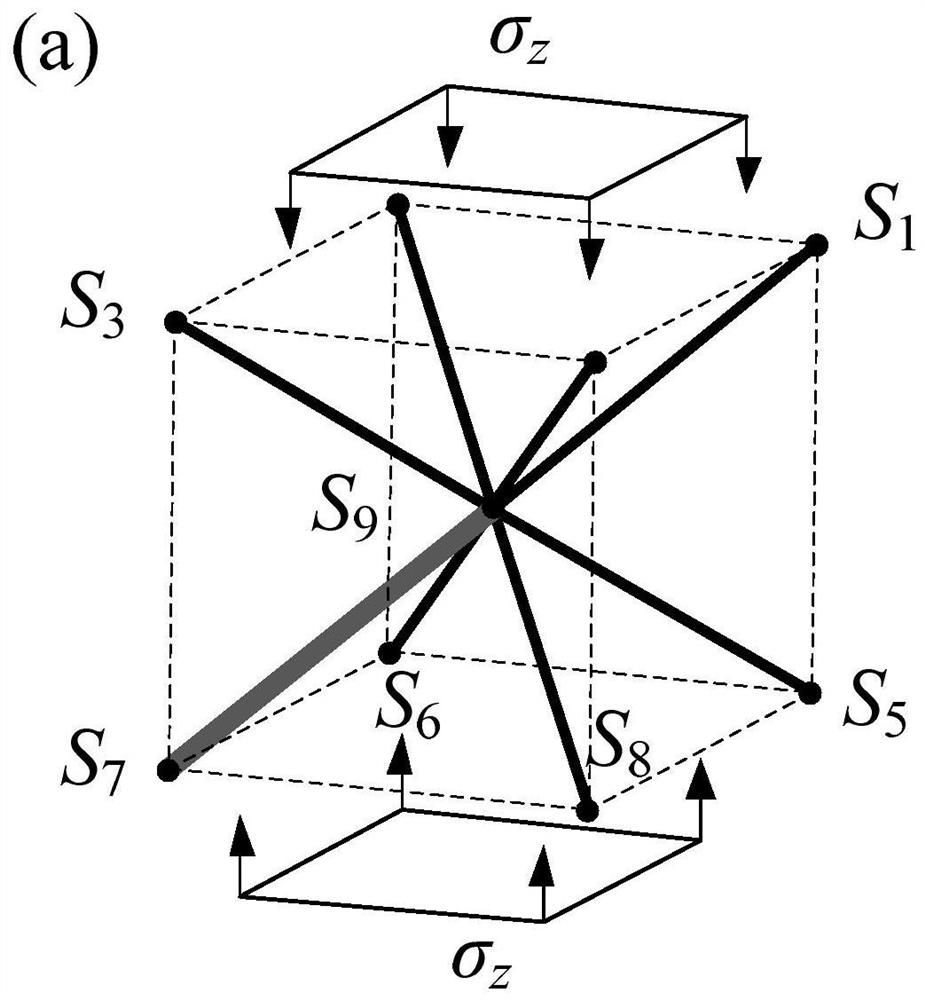

[0045] Select the unit cell as a cube whose side length is L to calculate the initial stiffness and plastic failure strength of the BCC variable-section lattice structure, as shown in figure 1 shown. The size of all the rods in the unit cell is the same. In this paper, the rod l S7S9 to analyze. figure 2 It is a schematic diagram of the cross-sectional size of the variable density rod. The variable density rod controls the uniform change of the radius through an arc line with a radius of R and a span of the rod length l. The expression of the arc radius R can be obtained through the geometric relationship:

[0046]

[0047] in,

[0048] Take the midpoint of one end face of the variable density rod as the origin, and the axial and transverse directions are respectively the x and y axes to establish Figure 4 The plane coordinate system shown is oxy, then the coordinate value of point M of the center of the arc is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com