Automatic robot cooking layered cabinet

An automatic cooking and robotic technology, applied in cabinets, manipulators, cooking utensils, etc., can solve the problems of complex mechanical gripper structure, single movement mode, unsuitable storage cabinets, etc., to enrich the movement mode, expand the application range, save money effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

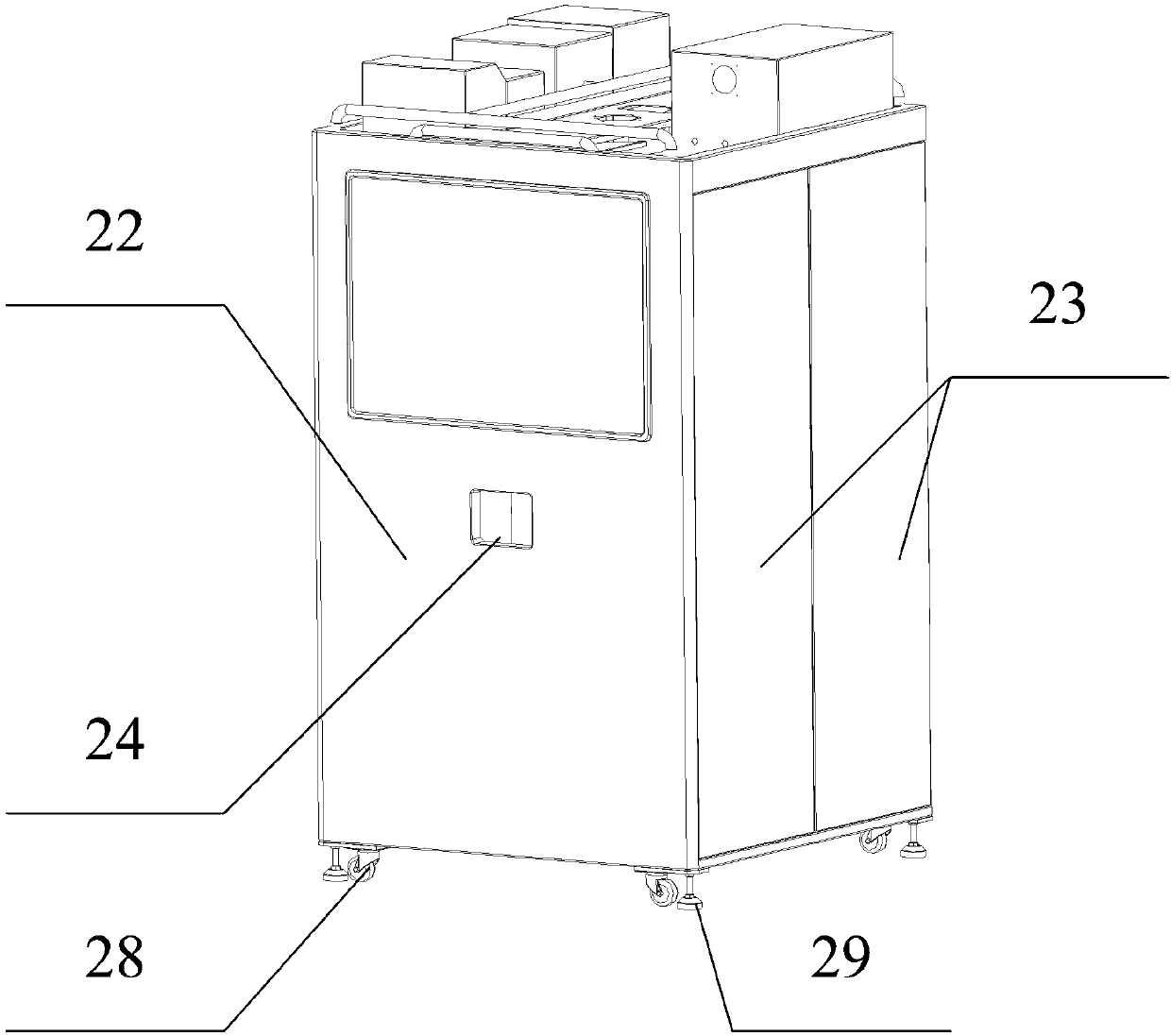

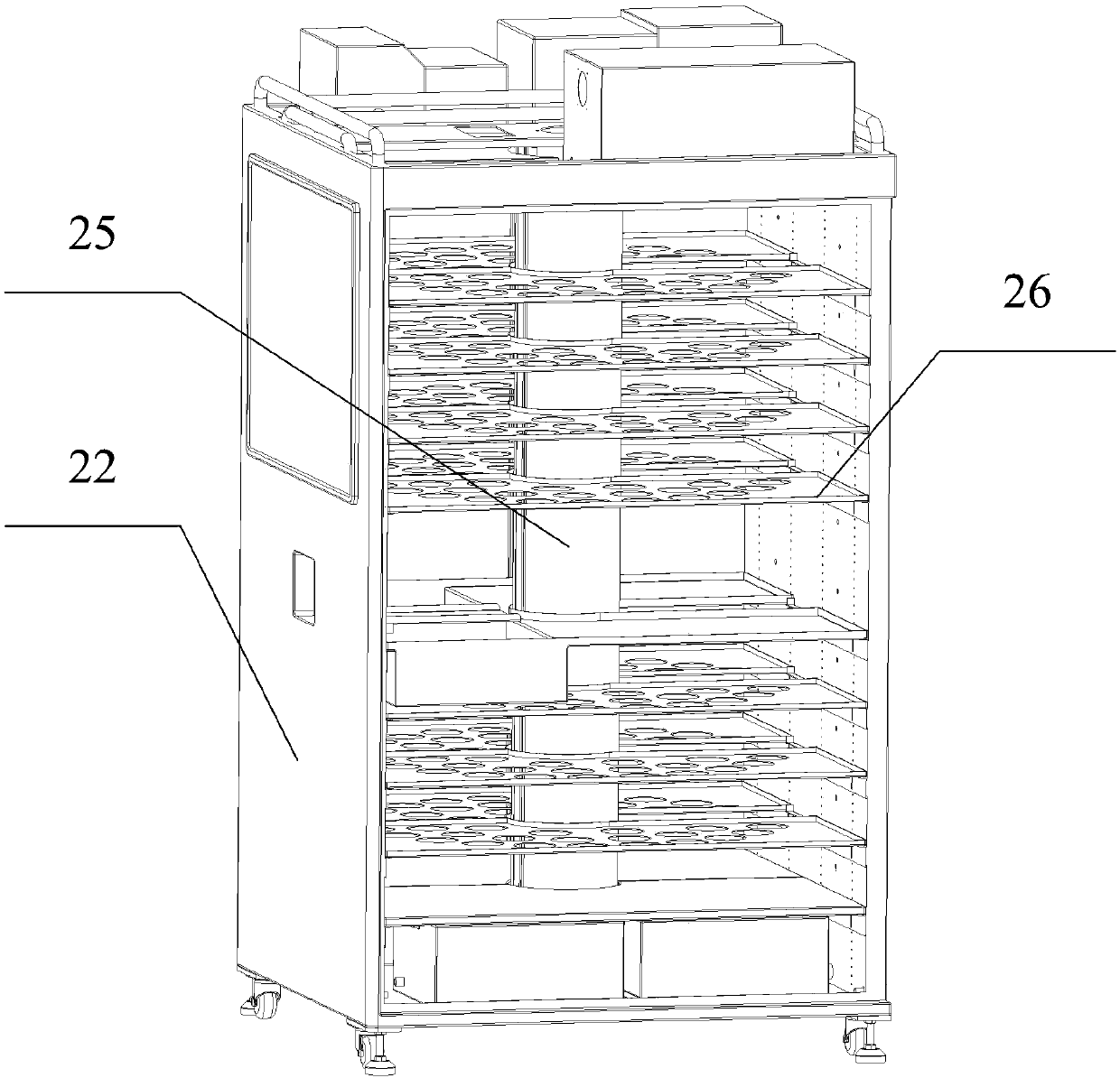

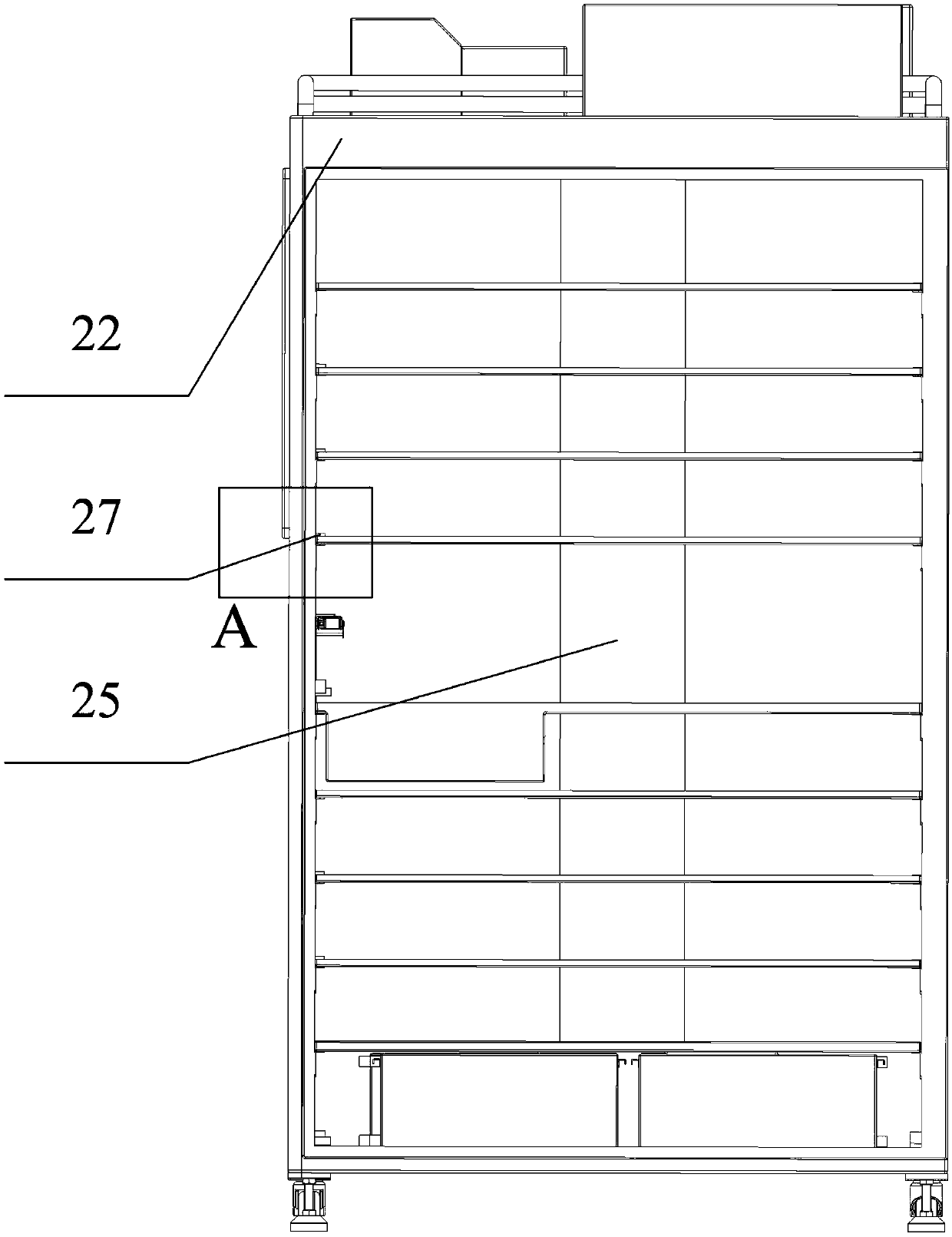

[0035] Such as Figure 1-Figure 7 As shown, the present embodiment provides a robot automatic cooking layered cabinet, comprising: a cabinet body, a plurality of pallets 26, a mechanical gripper and a protective cover 25, and a plurality of pallets 26 are vertically layered and arranged on the cabinet body successively Inside, the shape of the supporting plate 26 is U-shaped, and the U-shaped openings of the supporting plate 26 all face the same direction; the shape of the protective cover 25 is cylindrical, and one side is open; the protective cover 25 passes through the U-shaped opening of the supporting plate 26 It is arranged in the middle of the cabinet body; the inside of the protective cover 25 is a mechanical gripper channel, and the mechanical gripper can move in the mechanical gripper channel under the action of the lifting mechanism; Cooking with mechanical grippers.

[0036] There are multiple options for the connection between the pallet 26 and the cabinet, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com