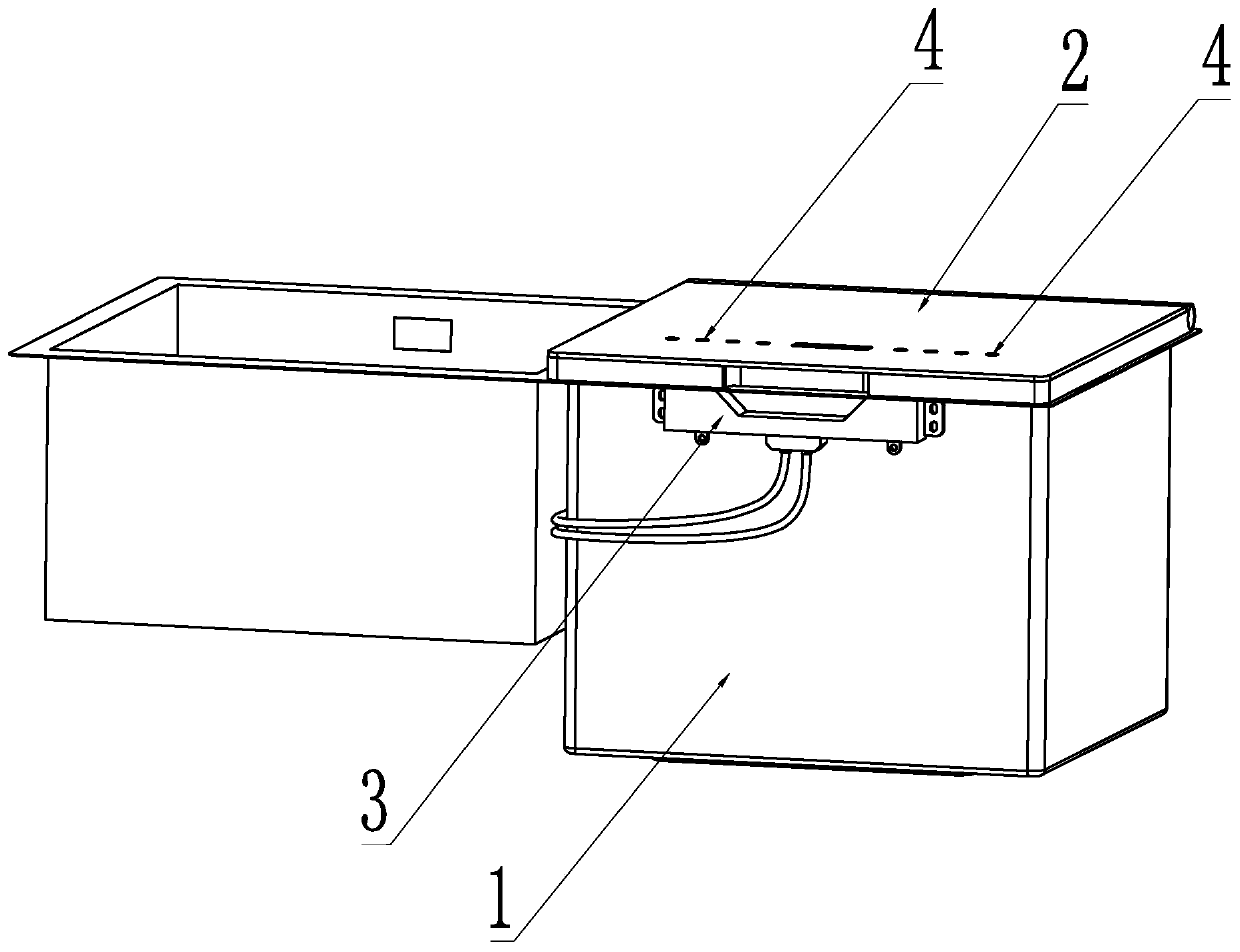

Control system for child lock for sink dishwasher

A technology of control system and dishwasher, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, applications, etc., can solve the problems of child lock failure, inconvenient use, and insufficient safety, etc. Achieve the effects of improved safety, high safety and reduced operation inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

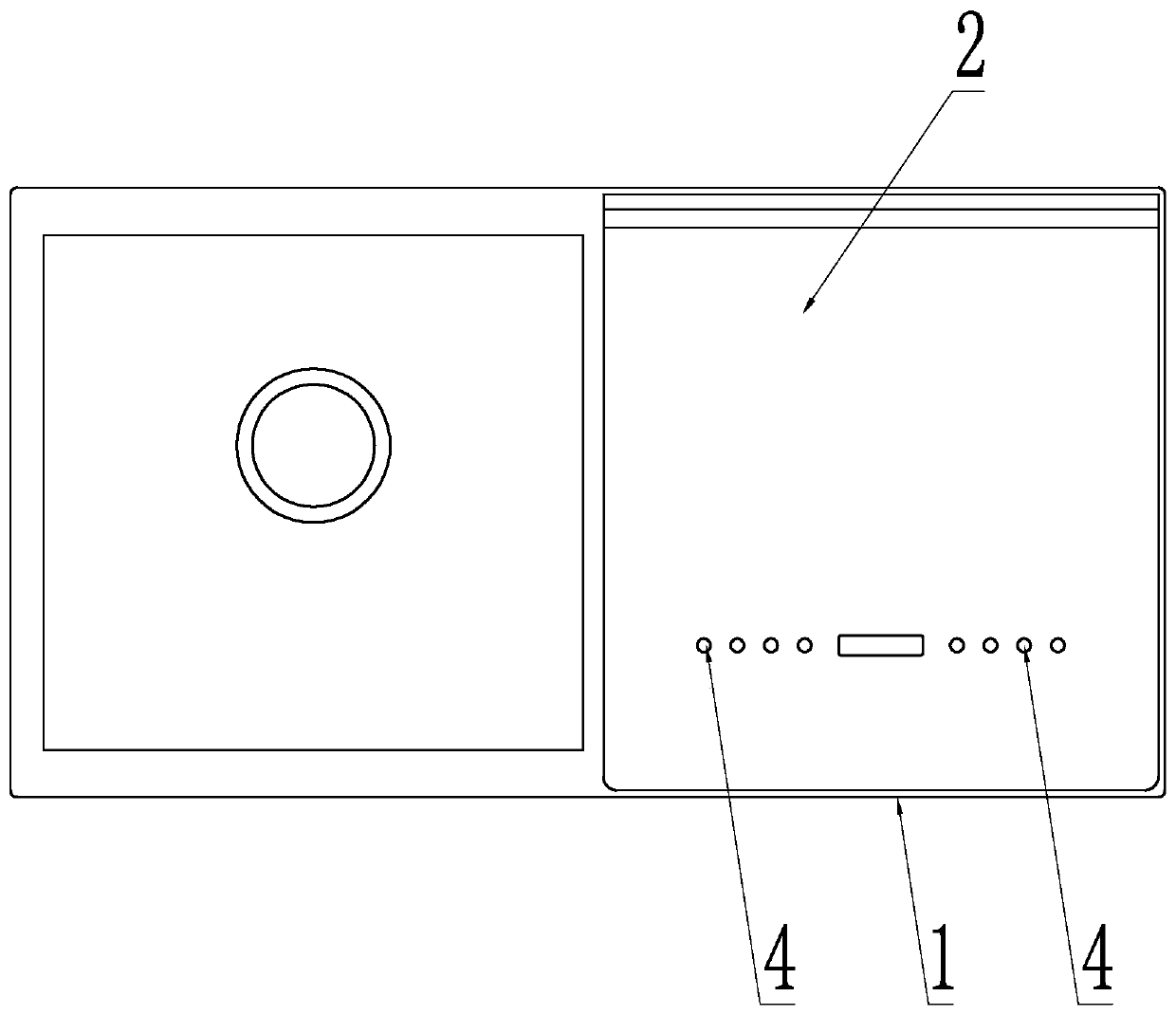

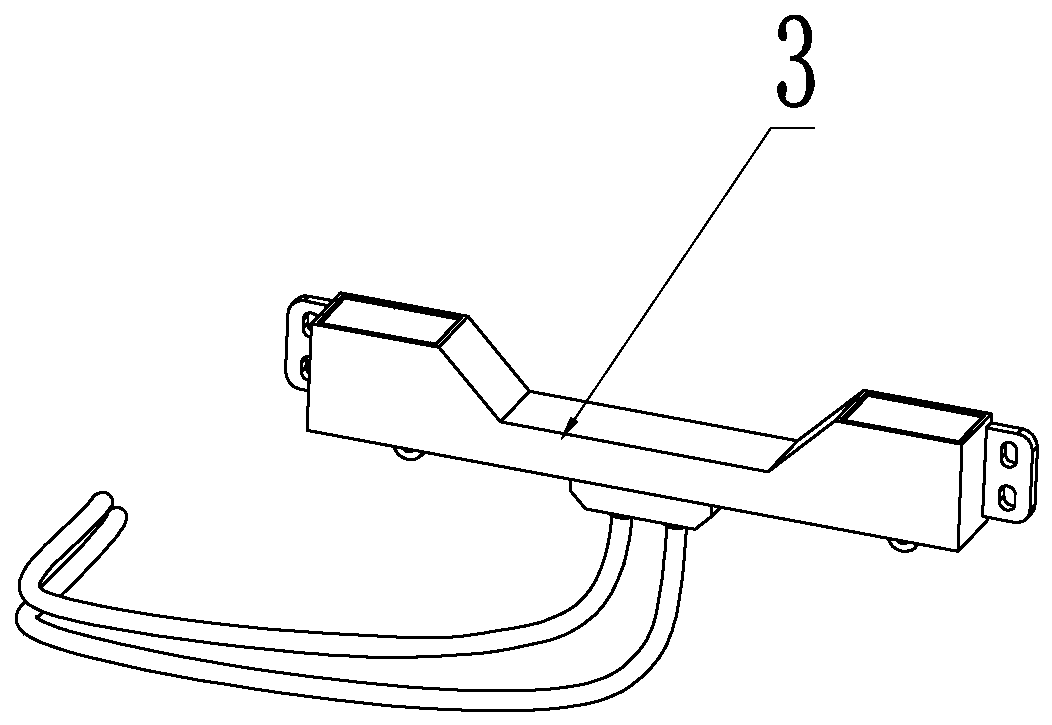

[0023] The control instructions include locking instructions and unlocking instructions. Wherein, when the electronic control lock 3 is in the unlocked state, if any two or more key switches 4 trigger the switch signal at the same time, the processor 5 receives the two switch signals to generate a locking instruction, and the locking instruction controls the electronic control lock 3 Switch to the locked state. Among them, when the electronic control lock 3 is in the locked state, the processor calibrates the two key switches 4 as specific key switches, and there is a gap greater than 80mm between the two specific key switches. If the switching signals of the two specific key switches are triggered at the same time Then, the processor receives the two switch signals to generate an unlocking instruction, and the unlocking instruction controls the electronic lock 3 to switch to the unlocked state.

[0024] Further, when the electric control lock 3 is in the locked state, the proce...

Embodiment 2

[0027] A first sensor 6 is provided between the washing tank 1 and the cover plate 2, and the first sensor 6 is electrically connected to the processor 5 for detecting that the cover plate 2 is opened or closed on the washing tank 1. The first sensor 6 can be installed on the sink 1 or the cover 2 or between the two. If the cover 2 is in the open state, the electric control lock 3 will fail. If the cover 2 is switched from the open state to the closed state State, the electric control lock 3 is reset to the unlocked state. The above-mentioned first sensor 6 detects that when the cover 2 is in the open state, the priority of the detection signal sent out is higher than the priority of the control command, that is, the control command is invalid when the cover 2 is in the open state, and the electric control lock 3 The power failure fails, thereby avoiding that the cover plate 2 is quickly closed due to the suction force of the electric control lock 3 in the open state, which may...

Embodiment 3

[0029] The basic mechanism of this embodiment is the same as the above-mentioned control system. The difference is that it also includes a first timer 7, which is electrically connected to the processor 5 and the key switch 4. In the unlock command, if two When the switch signal of the specific key switch is triggered at the same time, the processor 5 controls the first timer 7 to start timing. If the switch signal of any specific key switch is lost, the first timer 7 is cleared. When the accumulated time of the first timer 7 reaches the set value At a fixed time value, the electric control lock 3 switches to the unlocked state. The above-mentioned clearing of the first timer 7 means that the first timer 7 is reset to the initial state.

[0030] The above setting time can be set before leaving the factory according to different occasions, or can be set by maintenance personnel or users. The set time can be any time value from 1 second to 5 seconds. The first timer 7 can prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com