Cross hole deburring device

A deburring and cross-hole technology, which is applied in explosion generating devices, abrasive feeding devices, used abrasive processing devices, etc., can solve the problems of low economic benefits, large equipment investment, and high operating costs, and prevent shaking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

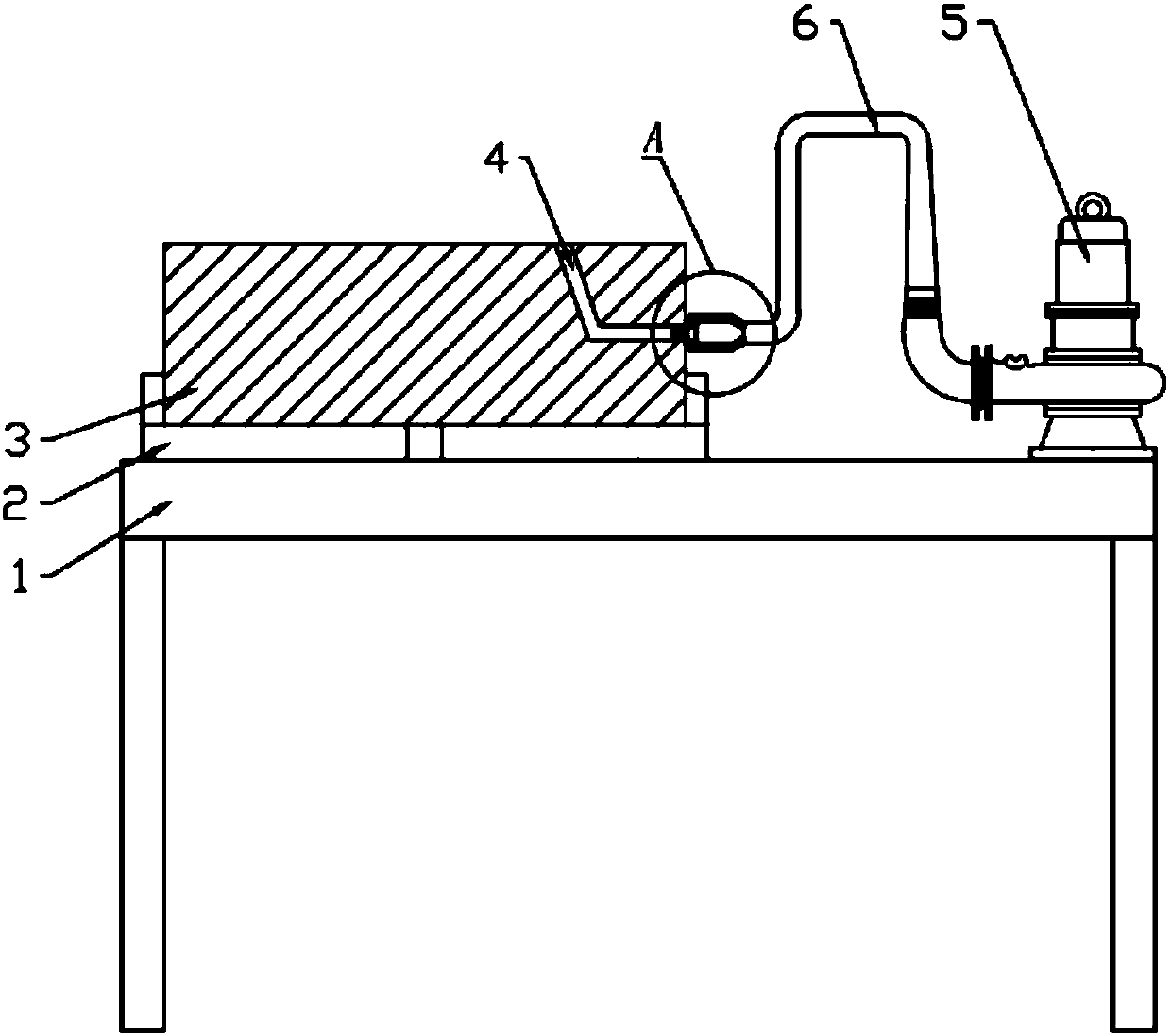

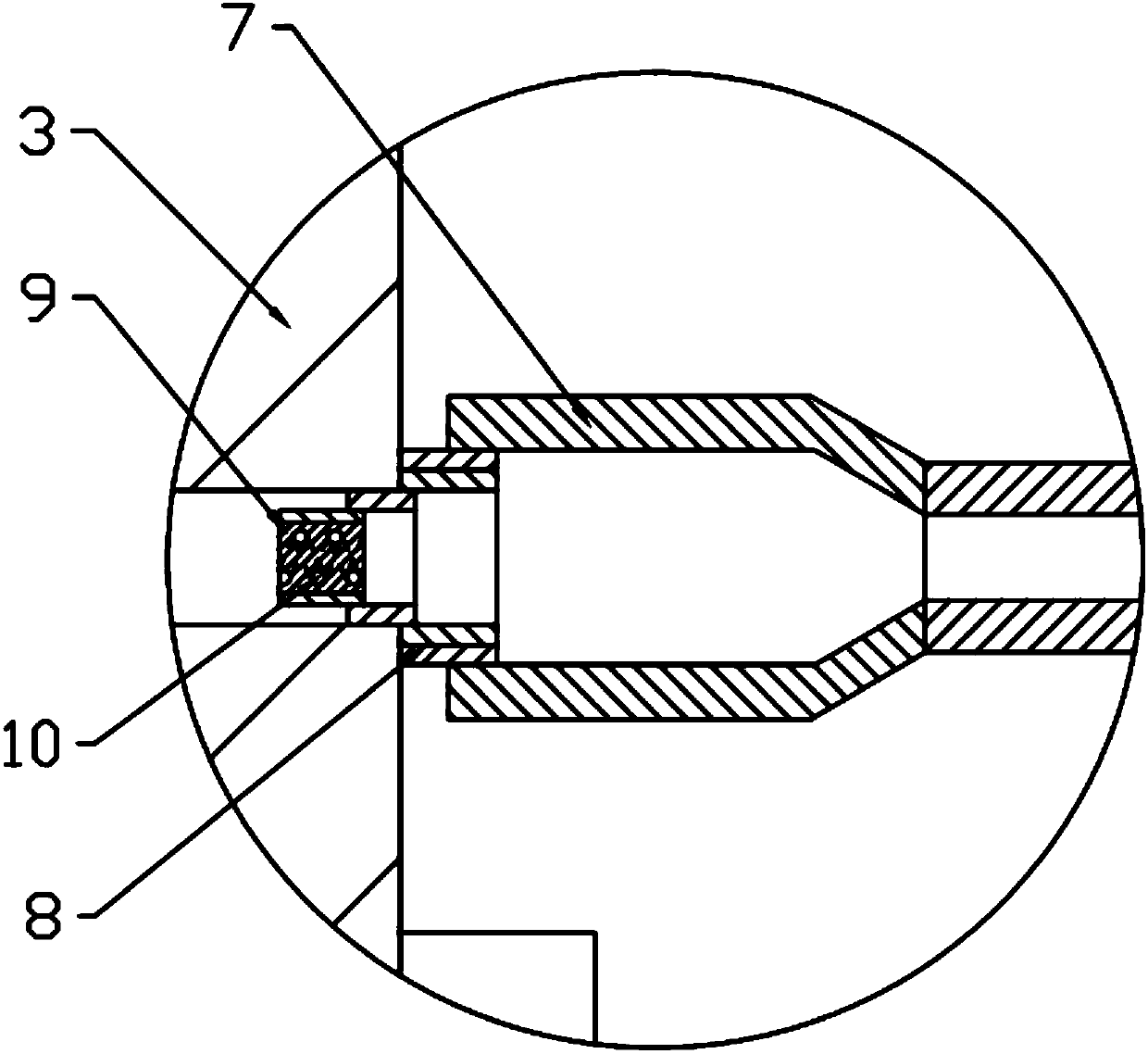

[0016] The reference signs in the drawings of the description include: frame 1, fixture 2, workpiece 3, cross hole 4, high-pressure water pump 5, metal shaped hose 6, nozzle 7, multi-section telescopic tube 8, plunger 9, water hole 10.

[0017] The embodiment of cross hole deburring device is basically as attached figure 1 and figure 2 As shown: it includes frame 1 and fixture 2 for clamping workpiece 3. Fixture 2 is installed on frame 1. High-pressure flushing device is also installed on frame 1. High-pressure flushing device includes high-pressure water pump 5, nozzle 7, multi-section telescopic Pipe 8 and flexible nozzle, one end of the nozzle communicates with the water outlet of the high-pressure water pump 5, the other end of the nozzle is installed with the nozzle 7, the nozzle 7 communicates with the nozzle, the nozzle 7 is cylindrical, and the nozzle 7 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com