Automobile rear floor structure

A rear floor and automobile technology, which is applied to the upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems of poor stiffness and strength of the rear floor, NVH performance degradation, easy deformation and cracking, etc., to improve local stiffness and improve NVH performance, effect of increased weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

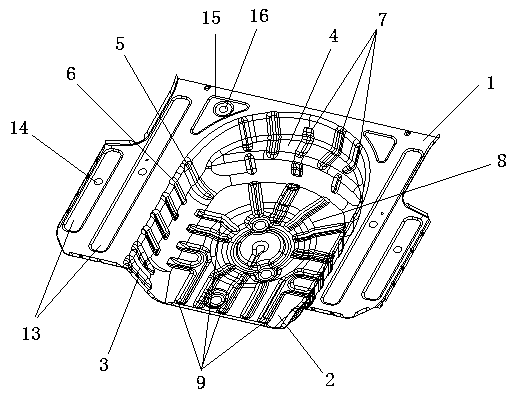

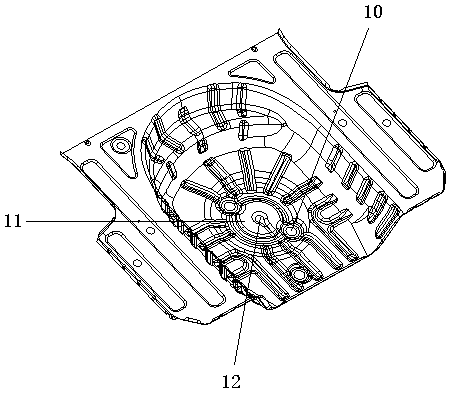

[0024] Such as figure 1 , 2 As shown, the car rear floor structure of the present invention includes an upper surface 1, a sinking surface 2 and a side elevation 3, and the sinking surface 2 is a "U"-shaped surface that is parallel and concave downwards from the upper surface 1, and the upper surface 1 The inner edge of the sunken surface extends vertically downward to the edge of the "U"-shaped sunken surface 2 to form the side elevation 3, so the side elevation 3 is a vertical "U" shape, and the arc inside the "U"-shaped side elevation 3 The shape part is a stepped boss 4, and reinforcement ribs are provided on the side facade 3, the sinking surface 2 and the stepped boss 4; 3 and the sinking surface 2 are transitioned through a circular arc, and the bending part of the stepped boss 4 is transitioned through a circular arc. Through the above settings, the structure of the rear floor of the automobile is simple, compact and coherent, strong in stability, strong and reliable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com